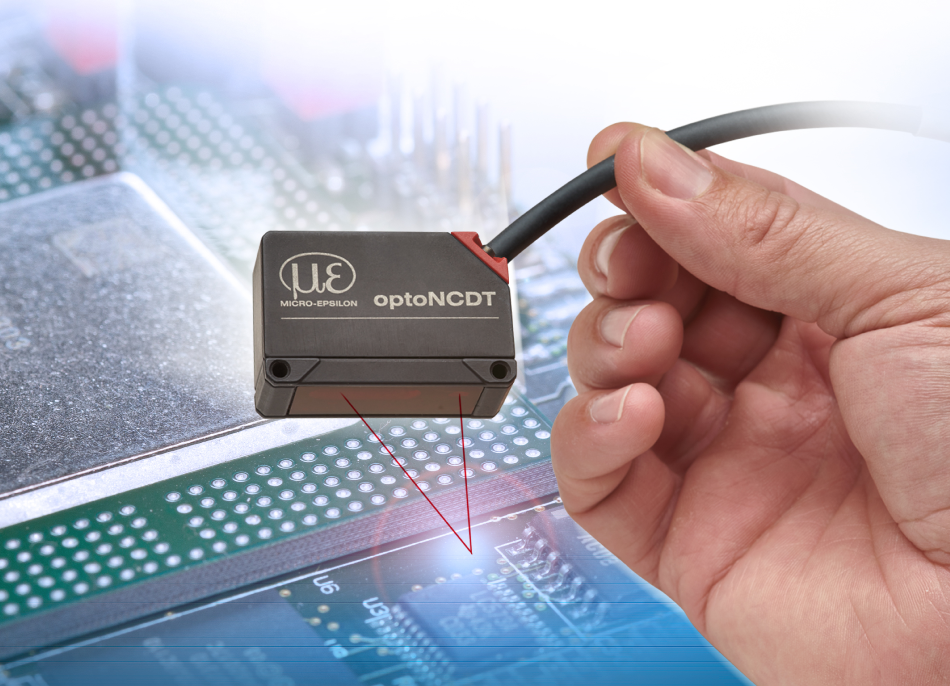

Extremely high production speeds and high precision are needed when manufacturing PCBs. So smart optoNCDT displacement sensors from Micro-Epsilon are utilized in pick-and-place machines.

They carry out reliable quality monitoring in the micrometer range. In PCB production, among other things, they examine the position of integrated components and measure the scribe lines of PCB panels.

Extremely compact design, high performance, and reliable signal adjustment with changing surfaces are the most vital characteristics of innovative laser triangulation sensors which ensure high precision results.

Whether it is medical devices, smartphones, or machine tools – almost every electrical device has a PCB. Yet, these devices are getting more efficient, smaller, and quicker, whereas the development cycles are becoming increasingly shorter.

This also means that the boards have to become much more powerful by utilizing highly integrated components. Miniaturization of individual components and switches, in addition to ever-growing packing density are crucial elements to fulfill the required performance.

The exact positioning of electronic components is vital to make sure that current in the form of information signals or electrical energy signals flows easily through the components.

For PCB manufacturing, these must be in the right place and also on the right level in order to properly connect them. The components must not be tilted in order to achieve smooth function.

High Requirements for the Measuring System

Sensors that examine the position of highly-integrated components in the line must overcome a series of challenges. Mainly, these are a small diameter of the focus due to extremely small components, high speed due to the highly dynamic production process, and high spatial resolution because of the minimal displacement changes which have to be detected.

Micro-Epsilon has designed the smart optoNCDT 1420 laser triangulation sensors for high-tech applications. These laser sensors do not affect the PCB or the highly-sensitive components and measure without contact. The non-contact measuring procedure allows the laser sensors to gather and process the measurement values very quickly.

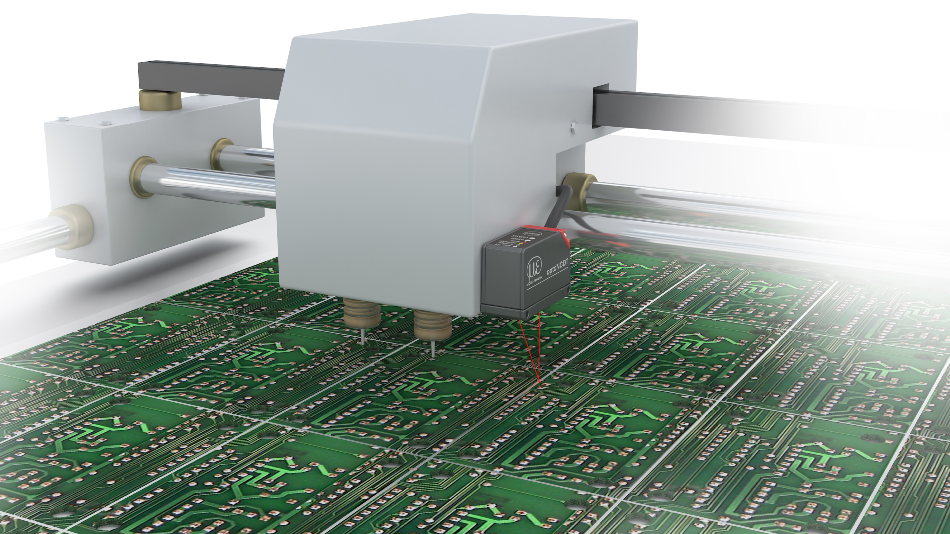

Quality Control in Electronics Production

In the quality control of PCB production, the sensors are placed so that they can measure the PCB from above. A traversing system guides them over the PCBs and its highly-integrated components. They detect dynamic processes directly in the production line, with a measuring rate up to 4 kHz.

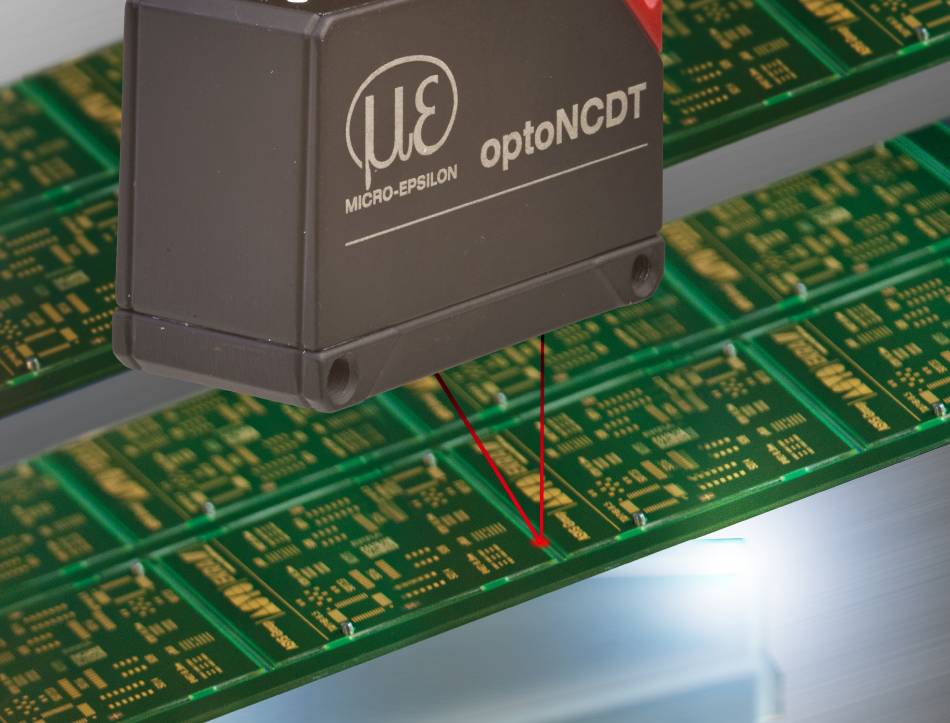

At only 46 x 30 mm, the sensor’s compactness and its integrated controller allow it to be integrated in restricted installation spaces. The smallest possible diameter of the light spot is only 45 x 40 µm, which permits high precision measurements on fine pins, as the light spot is able to be projected sharply onto them.

Optimum precision is required with the manufacturing of PCBs. The smart optoNCDT displacement sensors from Micro-Epsilon carry out reliable quality monitoring in the micrometer range.

Using modern sensors like the optoNCDT 1420 laser triangulation sensors reduces waste, enhances the quality, and lowers costs. The smart laser sensor reliably measures distance, displacement, and position with a repeatability from 0.5 µm.

Another vital prerequisite for reliable measurements on PCBs is a measuring procedure that can measure different materials, from metals to plastics, which is why the laser triangulation principle is the ideal choice. So, laser sensors from Micro-Epsilon supply the innovative Auto Target Compensation (short: ATC) feature.

The sensor measures on permanently changing surfaces, from shiny and reflecting targets to matt black, plus from bright to dark, especially with a PCB. The ATC makes sure that the exposure time adapts to the conditions presented by the respective measurement object.

In order to establish the measurement values, the laser sensor projects a red laser point at a wavelength of 670 nm onto the target. In order to hit the optical system of a CMOS line, the laser light is back-scattered in a certain reflection angle.

Just a small amount of light would reach the receiving matrix with quickly changing objects from bright to dark, without Auto Target Compensation. In contrast, the intensity would be too high when quickly changing from shiny objects to dark surfaces. The result would be inaccurate or even useless in both instances.

So, via the Auto Target Compensation, the Micro-Epsilon sensor regulates the exposure time and also the intensity of the light emitted during the measurement task in such a way that the reflection on the CMOS line is in the perfect range.

Next via the three-point relationship between the laser diode, the measuring position on the object and the depiction on the CCD line, the sensor calculates the distance values with micron accuracy. The values which are established can be fed in as digital or analog output signals into the plant and machinery control system.

Measuring Scribe Lines on PCB Panels

The scribing of predetermined breaking points into the panels for depaneling is another application in PCB manufacture. A PCB is made up of several panels or smaller PCBs which go through the production as one large PCB. As it simplifies board assembly, this type of bundling is needed for production reasons.

Usually, the scribe lines are generated by two opposing saw blades which cut a V-groove into the board, which should enable the small PCBs to be easily and cleanly depaneled, i.e. separated from one another, by the end of the production processes. The scribe lines are around 400 µm wide.

The scribe lines of the PCB panels must also be measured precisely. Here, the optoNCDT 1420 laser sensor is utilized, this is ideally suited to this application because of its unique combination of precision and speed with a compact design.

It is necessary to measure the scribe lines of PCB panels exactly. In this instance, the optoNCDT 1420 laser sensor is also employed because of its unique combination of precision and speed combined with a very compact design for this application.

The sensor detects inline if the keyway was milled into the panels exactly. The panels will break during the production process if the scribe line is too thin, which consumes resources and can cause damage to the machines.

The panels would fray during depaneling and break irregularly if the grooves are not milled deeply enough, which means that they no longer fulfill the quality requirements and a lot of waste is created.

Conclusion

The smart optoNCDT 1x20 displacement sensors are designed especially for the high requirements placed by Industry 4.0. Using modern sensors like the optoNCDT 1420 laser triangulation sensor from Micro-Epsilon ensures quality improvements while saving money and reducing waste.

The smart laser sensor measures distance, displacement, and position reliably, with a repeatability from 0.5 µm. Its extremely small measurement spot detects even the smallest of components, like pins on PCBs, with high accuracy.

With over 4000 measurement values per second, this sensor is designed for highly dynamic processes like those found in additive manufacturing or the electronics industry. Its small design and the integrated controller allow easy integration into systems and machines even when installation space is low.

Compact laser triangulation sensors

The intelligent surface control can balance the fluctuating intensity of the light, which is reflected during the measurement process when brightness or color changes quickly.

Especially with PCBs where bright and dark as well as matt and shiny objects are next to each other, this is a major advantage for achieving stable and micrometer-precise results.

The intuitive web interface enables the user to operate the sensor. It provides predefined setups for different measurement tasks. Additionally, up to eight user-specific settings may be stored and exported.

The signal peak selection, video signal display, and a freely adjustable signal averaging allow the optimization of measurement tasks. The ROI function (region of interest) permits, e.g., for interfering signals to be filtered out.

Fast commissioning is also possible. With easy measurement tasks, the user can use the multifunction button on the sensor. The characteristics which are combined by the optoNCDT 1420 are as unique as its design, which received the Red Dot Design Award.

This information has been sourced, reviewed and adapted from materials provided by Micro-Epsilon.

For more information on this source, please visit Micro-Epsilon.