Sponsored by CSEMOct 23 2020

Through the combination of a germanium microlens array, long wave infra-red bolometer, and an interference filter matrix, a compact portable multispectral system was created that was suitable for direct quantitative gas detection. Many regulated gases have absorption lines in the long wave infra-red, for example methane, NH3, N2O, SF6, and Freon.

Some applications include helping firefighters to locate dangerous gas leakages like ammonia, gas leakage monitoring in industry and specifically those dealing with compressed gases, like Low-Density PolyEthylene production with hyper compressors or fuel gas control on Liquefied Natural Gas carrier ships.

Detection in the thermal infrared wavelength region has applications in environmental testing, life science, agriculture and medical markets. Recent advances in Long Wave Infra-Red (LWIR) technologies are responsible for this fast market expansion, in particular the apparition of cost-effective LWIR bolometers cameras and the invention of IR glass, which enables inexpensive LWIR optics for high volume applications.

A number of materials and gases have direct spectral signatures in the LWIR, for instance ammonium sulfate or greenhouse gases. These elements are identified and quantified by attributing and quantifying these absorptions or reflections lines.

CSEM combines thermal imaging, filters and signal processing methods in this study to visualize and identify materials by utilizing their infra-red spectral signatures. This is useful to monitor gas emissions, gas leakage, or to distinguish materials.

One example of a use case was to help firefighters detect ammonia, which is highly toxic and common in the cooling systems of modern buildings. In these instances it is crucial for the firefighters to locate the ammoniac leakage so that they can isolate and seal it quickly.

Some other industrial use cases are when gas leakage monitoring can avoid large air pollution, the decrease of greenhouse gas contributions, monitoring in cargo ships for loss during transport, or minimizing explosion risks in industrial sites. A multispectral optical system in the LWIR is being developed by CSEM, it is composed of up to 35 spectral wavelengths.

A bolometer with 1024 x 768 pixels is utilized as the detector. Each wavelength forms its own spectral image in a narrow spectral band given by passing through a dedicated filter (Ref to patents: WO2018115320 & WO2018113939).

This provides 35 imagelets with a resolution of around 150 x 150 pixels. CSEM is developing Fabry-Perot filters based on porous metallic mirrors, which will result in cheaper filters when created in large quantities with microfabrication technologies and processes (patent pending) as an alternative to commercial interference filters.

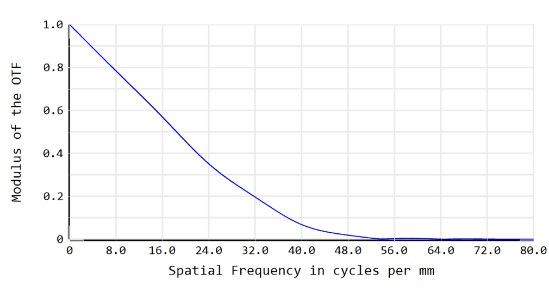

Figure 1. Image simulation and MTF quality parameter. Image Credit: CSEM

Optical simulation software (ZEMAX) was utilized to reproduce the optical system. Figure 1 shows an image simulation and a typical quality parameter (Modulation transfer function MTF). Figure 2 shows a picture of the 35 imagelets.

Figure 2. Example of an image with 35 imagelets. Image Credit: CSEM

By using a gas cell with IR transparent window, the system has been tested with different gases (NH3, N2O, SF6). The cell was filled with a target gas at different pressures. Imagelets at different wavelengths were collected.

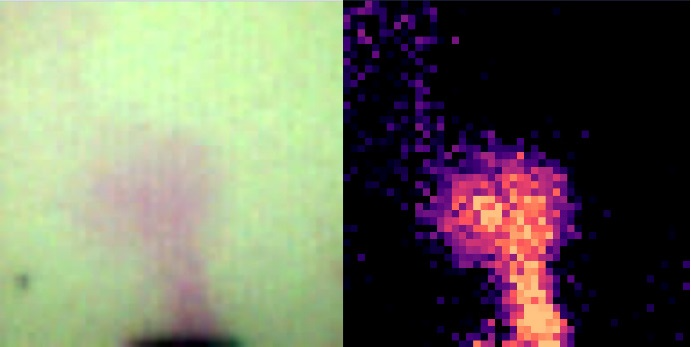

As anticipated, the absorption of the gas at the specific wavelength can be visualized directly on images (Figure 3 left). The software identifies the gas and can estimate its absorption (Figure 3 right).

Figure 3. Visualization of NH3 vapors coming out from a bottle: left composite image (left), concentration map (right). Image Credit: CSEM

It was possible to demonstrate the feasibility of visualizing a gas with a specific absorption in the Long Wave Infra-Red using the latest technology of thermal imaging and filters. Detection in the range of dozens ppm.m for gas like SF6 can be attained.

The system can be adapted to different gas panels by changing the microarray of filters and is portable. This project was performed in the frame of CSEM's MIP program, and CSEM would like to thank the Canton of Neuchâtel and the Swiss Confederation for their financial support.

Acknowledgments

Produced from materials originally authored by G. Voirin, C. Kündig, N. Cantale, B. Timotijevic, N. Niketic, R. Ischer, M. Krieger and L. A. Dunbar Revol from CSEM.

This information has been sourced, reviewed and adapted from materials provided by CSEM.

For more information on this source, please visit CSEM.