Method A/B is an assessment that can be carried out using a melt flow rate tester to determine the melt density value of a polymer at a particular temperature.

In a Method A/B test, both a Method A test and a Method B test are carried out on the same charge of material. The melt flow rate established from Method A is equated to the Method B flow equation and is solved to determine the apparent melt density.

The benefit of performing this assessment is to determine an accurate apparent melt density, which can be employed later in a solo Method B test to gain results that are equivalent to Method A. In Method B, no weighing or manual cuts of the extrudate are involved as opposed to Method A, where weighing and manual cuts by the operator are required.

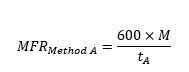

The mass melt flow rate from Method A is determined according to the mass of the extrudate(s) as per the below equation:

where (g) is the mass in grams of material acquired over time (sec). The value of ‘600’ is included to convent the unit of MFR to g/10 min.

Mass measurement of MFR using a Dynisco LMI5500 series. Image Credit: Dynisco

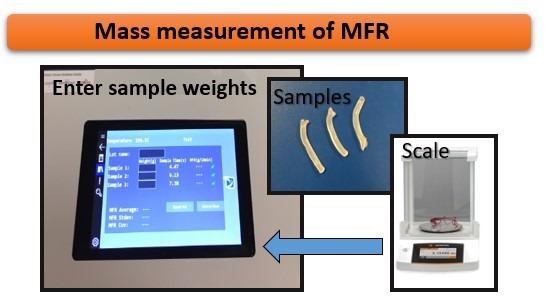

The equation below describes how the melt volume flow rate (MVR) from Method B is determined.

The value of ‘600’ is included to convent the unit of MVR to cm3/10 min.

Volumetric displacement measurement of MVR using a Dynisco LMI5500. Image Credit: Dynisco

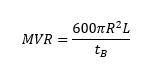

The ratio of the two values (MFR from Method A and MVR from Method B) provides a calculation for the polymer’s melt density in g/cm3 as expressed below.

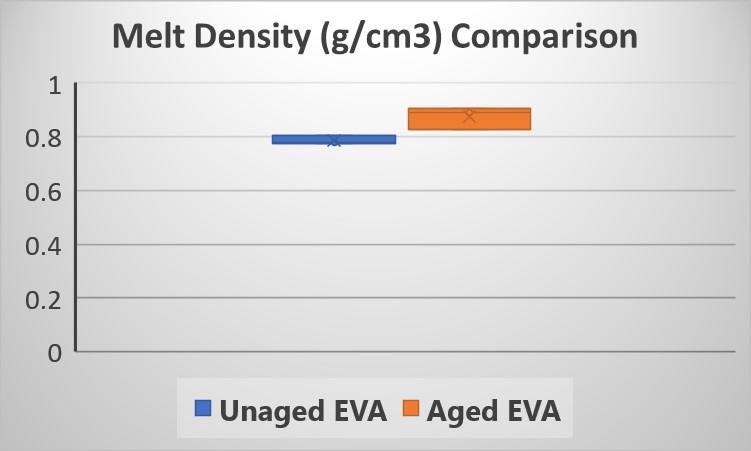

Figure 1 presents the apparent melt density results for two distinct EVA materials utilizing a Dynisco LMI series melt indexer (weight: 2.16 kg, test temperature: 190 C). For this assessment, three cutes were acquired within a one minute time interval for the Method A test and three flags with a flag length of 6.35 mm were acquired for the Method B test.

Figure 1. Apparent melt density results from Dynisco LMI series. Image Credit: Dynisco

This definition of apparent melt density forces the two test methods to correspond. The term ‘apparent’ melt density describes how the test is actually a correlation coefficient, which compels Method A and Method B to agree.

A true melt density could be identified if the extrudate were bubble-free, if there were no leakages past the tip of the plunger, and if several other small factors were taken into consideration.

MFR values can be acquired without manual weighing or cutting of the samples by using this apparent melt density value in Method B tests. It is important to note that the polymer’s melt density is a function of temperature. Additionally, the melt density of the material can be changed by fillers, reinforcing agents, among others.

Acknowledgments

Produced from materials originally authored by Azadeh Farahanchi from Dynisco.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.