Dynisco has accumulated almost 100,000 different configurations during its seven decades of operation. So how is one the right one for a particular task? A sensor is usually defined via the following specifications:

- Pressure Range

- Process connection

- Electrical output and connection

- Capillary configuration (rigid/flexible)

There are a lot more variables that come into play, but it is best to start it simple and explore these four specifications first and foremost.

Image Credit: Dynisco

Pressure Range

Generally, estimation of the pressure inside a plastics processing machine can be performed well enough to establish a good pressure range for a sensor. The standard working pressure should be within 20%-80% of the sensor's pressure range in order to ensure optimal balance between accuracy and lifetime.

Process Connection

Over time, a standard has been developed for threaded connections in plastics processing which is the ½”-20UNF thread with a conical sealing face.

There might be circumstances where various thread sizes or a flange connection is necessary. There are a number of options available from Dynisco to meet customer needs relative to the process connection.

Image Credit: Dynisco

Electrical Output

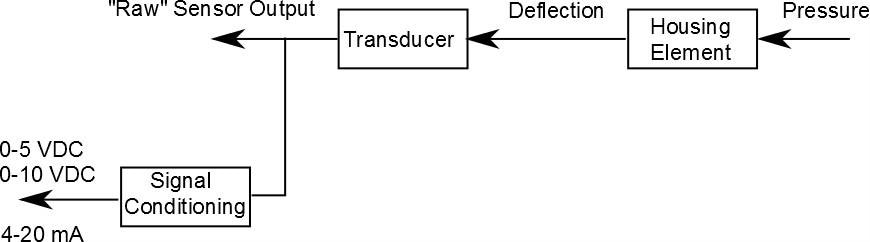

A pressure sensor is an electro-mechanical device that produces an electrical signal of a mechanical effect (pressure deflects a thin piece of metal) via a strain gauge.

The strain gauge adjusts its resistance by following the deflection of the metal piece. In the most fundamental case, the signal resulting from the strain gauge can be directly employed to feed a read-out device to display the pressure.

For the accommodation of industry-standard equipment like process control equipment, Dynisco offers sensors with various amplified output options like 4-20 mA or 0-10 V.

Image Credit: Dynisco

Capillary Configuration

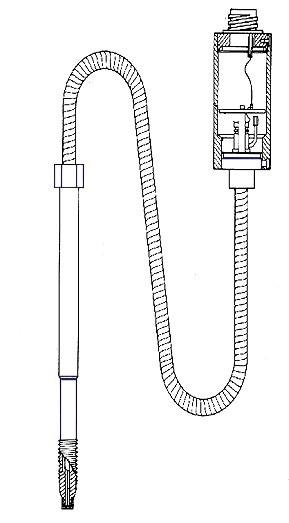

Typically, a pressure sensor has a liquid-filled capillary which bridges the process diaphragm (which is deflected by the process pressure) and the measuring diaphragm (where the strain gauge is bonded to).

This capillary is needed to generate a heat barrier, as the strain gauge does not have the capacity to withstand the usual process temperatures during plastics processing.

Also, the electronics of the sensor need to be isolated from any heat sources as much as possible. To establish an appropriate mounting location for the electronics can, a wide range of combinations of rigid stem and flexible connection lengths are available.

Image Credit: Dynisco

Download a Dynisco data sheet for information on the main product lines (e.g., PT or ECHO series) and specifications established in this article. As previously mentioned, there are often other parameters to consider, for example:

- Approvals and certifications

- Diaphragm coatings

- Diaphragm materials

When considering these points, it is possible to significantly narrow down the selection process and select the appropriate product for your needs.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.