Capillary rheometer is one of the most widespread melt rheometer techniques to discover the rheological characteristics and flow behavior of polymer materials under standard processing environments.

In this test method, a piston is used to force a molten polymer sample to flow through an interchangeable capillary die. The piston moves down at a range of speeds and forces are applied on the material.

The shear rate is determined by the rheometer according to the capillary die geometry at each individual piston speed. Due to this, it is crucial for the operators to employ an appropriate die type that offers the required testing condition for the specific application or material.

Dynisco offers a range of capillary dies with various entrance angles, diameters and lengths. As shown in Figure 1, each die has a unique part number, and the part number of each die is located on the edge side of the die.

Figure 1. The part number of a capillary die from Dynisco. Image Credit: Dynisco

Die Entrance Angle

The flow patterns of melt at the entrance of the capillary die is impacted by the entrance angle. Dies with a lower entrance angle restrict the creation of re-circulating corner vortices along with having more stable energy consumption and flow at the die’s entrance.

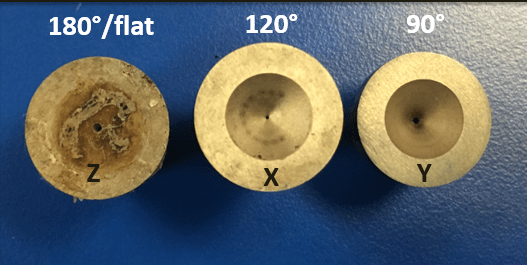

A lower angle also decreases elastic deformation in the polymer melt and benefits the shear flow. Capillary dies with entrance angles of 60° (W), 90° (Y), 120° (X) and 180° (Z) are supplied by Dynisco. Three dies with three different entrance angles are presented in Figure 2.

Figure 2. Capillary dies with various entrance angles from Dynisco. Image Credit: Dynisco

Die Length

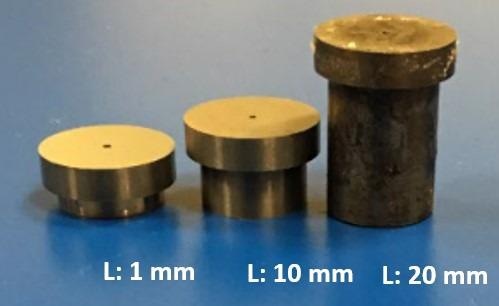

Dies with a longer length yield fewer percentage errors caused by a decrease in pressure in the entrance. In simpler terms, increasing the die length increases the amount of fully developed flow inside of the capillary die compared to the entrance area.

This is the case because time dependency is exhibited by viscoelastic polymer melts. When a longer die is used, the polymer melts remain inside the die for longer, which causes the material to forge the elastic deformation applied at the die entrance.

A long die (L>15 mm) is recommended for the measurement of shear viscosity. A short die (L<15 mm) is recommended for the measurement of elastic characteristics, for example, the wall slip velocity, the die swell ratio, and others. Three dies with varying lengths are depicted in Figure 3.

Figure 3. Dies with various lengths from Dynisco. Image Credit: Dynisco

Die Diameter

The applicable range of the shear rates in the rheometer is impacted by the diameter of the die. Dynisco supplies capillary dies with diameters varying from 0.3 mm to 3.00 mm, which allows the rheometer to generate shear rates ranging from 0.02 1/s to 277,000 1/s.

Capillary dies with diameters of 0.75 to 1.5 mm normally generate shear rates, which are equivalent to those produced by an injection molding or extrusion procedure.

Dies with a larger diameter reduce entrance pressure drop, extensional deformation, die swell, and slippage and yield lower shear rates. Two dies with different diameters are presented in Figure 4.

Figure 4. Dies with various diameters from Dynisco. Image Credit: Dynisco

Acknowledgments

Produced from materials originally authored by Azadeh Farahanchi from Dynisco.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.