Over 50 years ago, Dynisco developed the first liquid-filled capillary melt pressure transducer. This technology has demonstrated that it is extremely stable, accurate and repeatable for high pressure and high temperature pressure measurements.

However, changes in environmental temperature can still occur throughout the extrusion process. Such temperature changes – mainly apparent during startup - can generate moderate to severe shifts in output.

It is widely accepted that a pressure transducer will need some level of calibration to re-zero the unit at process temperature subsequent to installing the pressure sensor on the process.

If the temperature fluctuates during the process or when re-zeroing the pressure at startup becomes an issue, the Dynisco™ SPX-T Series is the perfect solution.

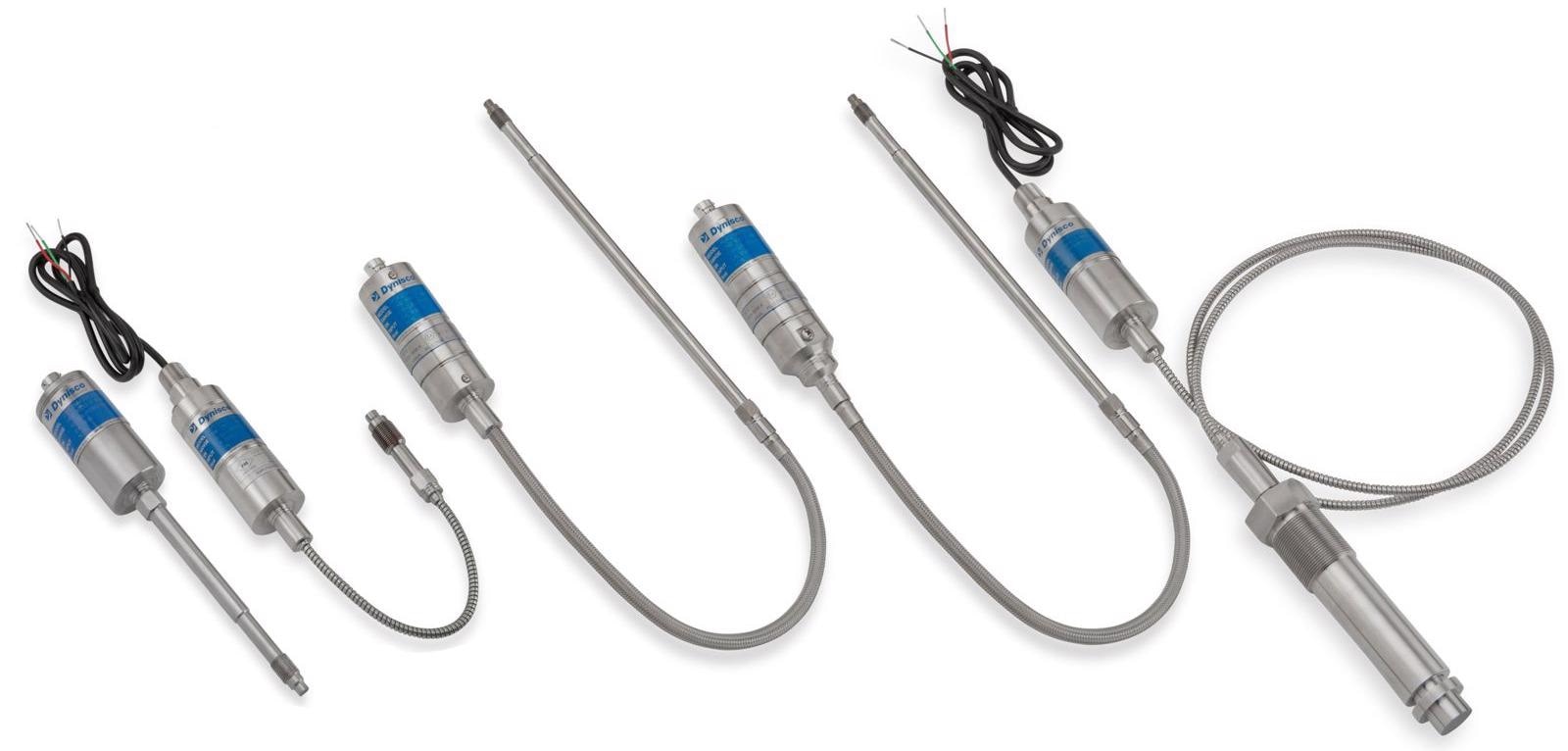

Image Credit: Dynisco

The SPX-T is a smart pressure transmitter that incorporates a novel process temperature compensation and Dynalarity™.

This amplified transmitter is an all-welded construction developed for use in hazardous locations and can be acquired in a range of processes and electrical connections. As well as HART™ communication, process temperature output is also available.

Temperature-related drift is limited, and accuracy is enhanced because temperature compensation is predicated on an RTD measurement that compensates for variations in the process temperature.

With the SPX-T series, it is not necessary to re-zero for temperature changes post-installation. DynaLarity utilizes a progressive algorithm that will linearize offsets as a result of process effects on the sensor. Combined Temperature Compensation and DynaLarity facilitate as much as an 80% decrease in temperature-related drift.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.