For more than 60 years, Dynisco pressure sensors have been put to use in a wide range of applications all over the world.

As the original patent holder for the melt pressure sensor employed in extrusion, Dynisco has maintained its status as a global industry leader in this technology by closely working with end-users to meet the ever-changing demands of the plastics market.

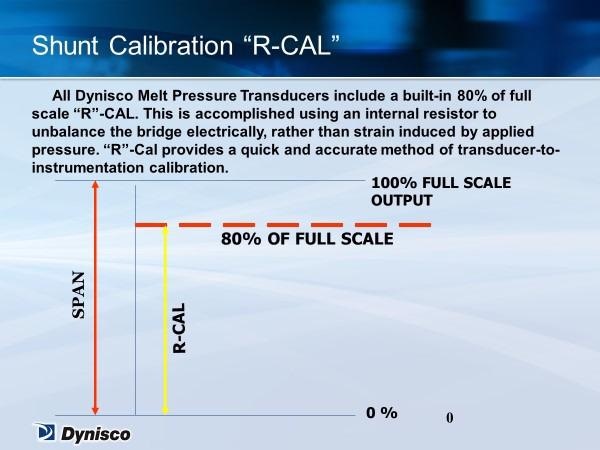

This article highlights the unique feature known as ‘R-Cal,’ which is a standard for the bulk of the Dynisco pressure sensor product portfolio.

R-Cal stands for ‘resistance calibration,’ and it is used to influence a known signal output from the pressure sensor, which with no pressure present is at rest.

The signal can be measured in millivolts, milliamps, or volts and is scaled to exactly 80% of the full-scale value.

When a pressure source is absent, confirmation of the instrumentation scaling can be complicated. Thus this feature offers a means to test that the sensor and instrumentation have been appropriately scaled together.

For example:

A Dynisco model PT462E-10M-6/18 possesses a signal output range of 0-33.3 mV (3.33 mV/V). The pressure range is 0-10,000 psi, +/- 0.5% of the full-scale range.

When engaging the ‘R-CAL’ via the two dedicated pins CAL 1 and CAL 2, there will be precisely 80% signal output which is the equivalent of 26.64 mV.

If the instrumentation has been correctly scaled on the display, the user should expect to observe 8000 psi, while the R-CAL has been shunted via an attachment of the dedicated pins.

A number of instruments, including the Dynisco UPR900 (UPR800/UPR700/UPR690), have an integrated sequence for carrying out this calibration check.

The following slide shows what this feature looks like:

Image Credit: Dynisco

It is of key importance to note that this procedure is used to confirm that the instrumentation is accepting the signal range in the appropriate manner and is not intended as a means for verifying the mechanical response to the pressure of the sensor itself.

In order to verify pressure is being read correctly by the pressure sensor, the user requires a calibrated pressure source, such as a hydraulic pump or a deadweight tester.

For this purpose, Dynisco model PPS1100 (Portable Pressure Source) is available, which can facilitate pressure ranges up to 10,000 psi.

R-Cal is a feature that has assisted several users in the verification of their instrumentation without having to take out equipment from the process. This feature is one of the many that separates Dynisco pressure sensors from its competitors.

Contact Dynisco’s team of experts to find out more about features that may be available for any models you are currently using so that Dynisco can help facilitate your continuous improvement efforts.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.