A common assumption among a majority of the end-users of sensors is that solids can be reliably tracked only by using a costly technology, like radar, or by derating the distance of an ultrasonic sensor by 50%. As a matter of fact, this assumption has been effectively accepted by the industry itself.

However, this article seeks to contest this idea and asks whether this is true or simply an accepted myth. Figuring out how to combine the right sensor properties with the materials and application needs is the ultimate way to save cost and assure reliability.

Individuals should ask themselves and the suppliers “what makes a product a consistent sensor for every application?” All product models are not completely standalone products for all kinds of applications, and this applies to any type of technology.

The reason for this is all models are not a 'one size fits all' solution, with the same transducer or sensor being the perfect match for every special variation that may change from one situation to another.

However, it is a general phenomenon for individuals to purchase many of the same kind of product to outfit everything within their cost.

It is acceptable to do this if the environments and materials are sufficiently similar where they actually do not change, or if the product turns out to be the ideal fit with the best value because that would reduce the cost along the way.

This article assesses the enormous realm of solids and the standard performance of ultrasonics when utilized with solids and, at the same time, it questions the general practices of derating ultrasonic distance ranges by 50% and the over-implementation of more complicated and costly technologies instead of better-valued alternatives.

It also focuses on how a consistent transducer, and the manufacturer’s expertise with the science of sound, considerably influences the performance, reliability, and quality of the ultrasonic sensor for use in any kind of environment.

Ultrasonics can be used much more effectively in a wide range of environments, including for use with solids, although the industry has a mistaken belief of how to apply the technology in these environments.

Ultimate performance results can be obtained by interpreting what kinds of features in the ultrasonic design, of the sensor and the transducer, affect the reliability of the sensor when used with or in solids.

Ultrasonic sensors are a highly economical solution for measuring solids, and identifying a method to select the most consistent products helps control across the required outcome, reduces the cost of ownership, and may even decrease the requirement for more costly technologies.

Overview

Solids are different from liquids and come in a wide range of sizes and shapes. Ultrasonics, in the industry, are traditionally the preferred product for use with liquid-level measurement and also, on the other end of the spectrum, collision avoidance.

But the real functionality of how ultrasonics work (or can be ideally used) in such applications has not been completely understood because they are 'accepted.'

Similarly, it is 'accepted' that when there is a requirement to track a solid material, one must look at the stated distance range of an ultrasonic sensor and reduce it in half to obtain the right precision and realize a consistent measurement.

The fact is that this is an over-generalization and usually makes the customer eventually choose a more expensive product than is needed to satisfactorily and adequately do the job.

End users are often convinced to purchase either an overpowered ultrasonic system or a more costly technology alternative, like radar. This article seeks to question the concept of what is 'accepted.'

All ultrasonic devices operate in the same fundamental way—they send a brief pulse of ultrasonic sound toward a specific target, which subsequently reflects back to the sensor.

Such kinds of sensors quantify the time from when the sound pulse is sent until the echo comes back to the sensor and use the speed of sound in the medium to estimate the distance to the target.

But not all ultrasonic sensors are created the same. With regard to solid measurement, end-users should consider using better-matched products for every application because this would be much more economical.

End-users should have more conversations about the materials they are tracking and how specific sensor features can be either a hindrance or help to both their tracking requirements and to the bottom line.

There might also be situations where a well-informed ultrasonics producer can provide a modified or new product that decreases cost and exceeds in a certain scenario. To be a quality product with excellent reliability, all aspects of the sensor should work reliably and properly to make sure that precise distance measurements are continuously achieved.

While a few individuals may think that quality does not impact the overall consistency of an ultrasonic sensor, that is simply not the case.

This article highlights the fact that actual quality results in durable products that continue to fulfill specifications and perform for years and even decades. But if it does not, it is not the real quality and it is definitely not reliable.

People who understand this basic point will save costs on their projects, and for their firms, because they will invariably select high-quality sensors, manufactured with high-quality parts, which will exceed expectations in terms of performance for a remarkable period of time.

This will prevent the costly downtime that comes with using substandard products.

There are many factors that can impact sensor reliability, particularly when utilized with solids. This article will discuss a few of these factors in the following sections. The type of beam angle, the quality of the transducer construction, and the general nature of the solid material that one is attempting to track are all crucial factors.

Some solids are based on chemicals, some are dense, some are bulky, some have dust, and all have variations. A few solids need to be monitored within a highly controlled and specified distance range, whereas others are not so rigorously regulated. Certain solids combine with liquids to produce a slurry, whereas others are maintained in low humidity.

The electroacoustic transducers that send the pulses of sound and receive the reflected echoes inside a product could create some confusion for the average buyer.

Similar to the old adage 'buyer beware,' many people fear the risk of choosing a substandard product, and hence they often end up buying a much more costly or relatively more powerful product than is actually needed.

The craftsmanship of the transducer design, and the quality of the transducer, can considerably impact the performance and reliability of the sensor where it is utilized. If an ultrasonic sensor provider has more knowledge about the physics associated between the materials and the sensor it will operate with, it would be better for the buyer.

Most often, customers do not clearly disclose their monitoring situation. There could be many reasons for this but whatever that can be shared with a well-informed manufacturer will lead to a better-matched product for the application.

There are two crucial areas that influence the reliability of the transducer that should be taken into consideration. The first area is to make sure that the transducers have the right mechanical and electroacoustic design for every application. The second area is how the transducers are manufactured.

The Relationship Between Design and Application

The mechanical and acoustic design of the real sensor is interrelated in several respects because one influences the other. Hence, a robust understanding of both areas is crucial for the proper design of the transducer.

But there are also some distinct differences between the two. The acoustic items comprise the attenuation of sound, frequency, beam angle, and beam type, among others.

The mechanical items comprise the materials employed in fabrication so that the transducer does not hold up and also performs well in various applications, mediums and environments.

The association between the mechanical and acoustic design items with the environment is crucial for the design and evaluation of the reliability of ultrasonic transducers and sensors.

Different solids can influence the reflectivity of the echo and thus impact the apparent performance and reliability of ultrasonic level sensors in these environments. Based on the density, the physical features of the kind of solid measurement application will help a sensor salesperson to correctly guide a buyer.

But people should consider this aspect meticulously—are they are looking for guidance in choosing the right product? Are they going through a distributor or a manufacturer? Are they speaking to a firm that has an inherent knowledge of the advantages of the different products that can be used?

Are they actually buying a product that will provide the perfect value for their business, or is actually the ideal value to the individual selling it to them? Are customers being guided to a more costly product that will also increase the cost of ownership for their business, but is possibly the accepted solution?

It may be in customers’ best interest to do some critical thinking before committing to a technology product or type. Based on their application, customers may place more emphasis on reliability than precision.

Similarly, customers may place more emphasis on precision than range and they may have a greater need to track inside a particular range with more reliability than is needed beyond what is specified.

All these are crucial data to communicate when choosing a sensor. An understanding of the density, physical structure, and nature of the solid and how it impacts the echo of an ultrasonic will allow customers to find out the type of ultrasonic that they may prefer to try.

Certain materials can impact some ultrasonic performance more than other ultrasonic performance, and a few materials have a more dramatic impact than others.

When this was looked more closely, it was found that certain materials ultrasonics may have to be derated for distance. But not by the suggested 50% for use with all solids. In a few cases, materials ultrasonics only had to be derated by 25% to 30%, and in other scenarios, only by 40%.

The amount that one must derate the ultrasonic sensor is also influenced by the quality of the transducer, the beam angle, and how far away the sensor actually needs to be to the target material.

A few close-range midrange ultrasonic sensors, like MassaSonic FlatPack, have wide beams that are developed for use with irregular sensors that work well with solids and the inconsistent nature of how they accumulate inside a bin or tank.

The burst of sound from the sensor creates a well-defined echo from the smooth surface of a liquid. But a turbulent surface or a non-uniform surface created by solid material in the tank can scatter the reflected echo and it will not be correctly identified by a sensor that has a narrow beam angle.

A wide beam angle will generate detectable echoes. The solid material in the tank, like grain, can also create a sloped surface, rather than the flat-level surface produced by a liquid.

This can make the sound beam reflect off from the sensor so that the echo cannot be identified. Equally significant is the design of the radiation pattern of the transducer.

A majority of the ultrasonic sensors employ transducers that apply the teachings of U.S. Patent 3,928,777 and U.S. Patent 4,011,473 issued to Frank Massa in 1975 and 1977, respectively. For any frequency of operation, transducers with this design have a 10° beam angle, or 8° system beam angle.

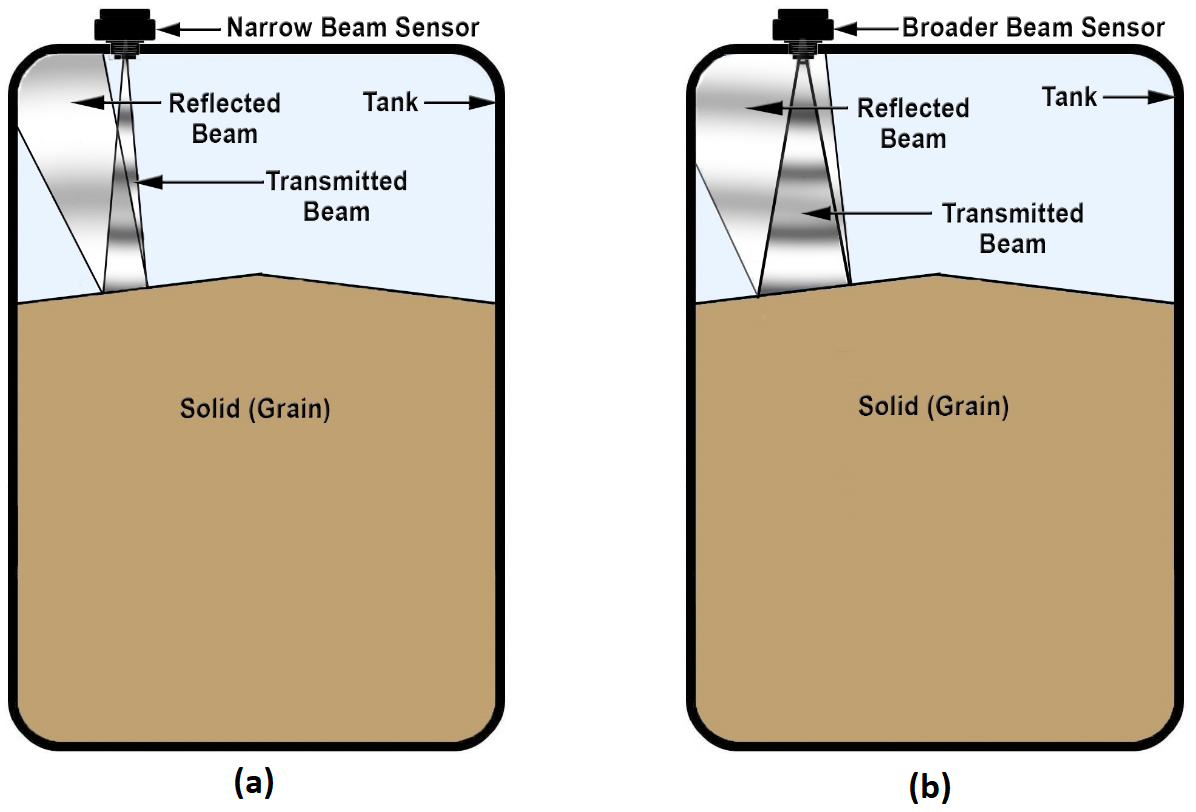

While this is excellent for flat-reflecting surfaces, a wider beam angle is required if the reflecting surface is uneven, turbulent, or tilted in relation to the axis of the sound beam. Figure 1 shows a pair of tanks comprising a solid material, like grain, with a slightly sloped surface induced by the penetration of the grain in the tank from the top.

Figure 1(a) illustrates how the echo produced from a narrow beam sensor reflects from the sloped surface of the material inside the tank away from the transducer, which means it cannot be detected.

Figure 1(b) illustrates that the echo from a wider beam sensor comes back to the transducer after reflecting from the same sloped surface of the material inside the tank, and hence it is detected.

Figure 1. Illustration showing a narrow beam sensor and a broader beam sensor mounted on tanks with their conical beams reflecting from the sloped surface of solid material such as grain. (a) Narrow beam reflects away from sensor and echo is undetected. (b) Broader beam reflects back to sensor and echo is detected. Image Credit: Massa Products Corp.

Developing a transducer that is adapted for the environment will provide more precise outcomes, and it will aid the ultrasonic in its performance within the medium for an extended period of time. Both the materials and acoustics should be fashioned to obtain the required operation in the environment.

The reliability and quality of the sensor customers are using, or building, is again considerably improved by the quality of the transducer within. Figuring out the materials and the acoustics can give users an edge.

Acoustic characteristics tend to alter in different mediums and can provide a wrong impression that they will not operate as good as other technologies.

When the supplier of transducers/sensors is really knowledgeable with regard to the materials and the acoustic properties, as well as skilled in the development of electroacoustic devices, one will find several new truths relating to the performance, cost-effectiveness, reliability and success of sonar and ultrasonic measurement in a wide range of mediums and applications. This saves both time and cost.

To study this idea in more detail, the acoustics are further discussed. Transducers can be developed to work at various ultrasonic frequencies and to have different patterns of acoustic radiation.

Sound energy is absorbed as it moves through the atmosphere. If the frequency is higher, the attenuation of the sound pressure for every inch in the path from the transducer to the target and then back to the transducer will be larger.

Hence, if the distance to the target is greater, the frequency of the transducer will need to be lower. An acoustic expert will be able to identify what the proper beam pattern and frequency should be for any specified application.

It is not right to believe that specific applications need some beam width or “standard” frequency. The expertise of a transducer designer about a certain application will result in a better sensor and transducer, ensuring a performance that outpaces all others.

Sensor Reliability

A sensor is essentially a system that comprises the sensor housing, electronics, and the transducer. The reliability of the ultrasonic sensor is considerably influenced by the quality of the transducer and the association between the materials and the electronics.

This underscores the idea of working with a firm that actually can consider customers’ application concerns to either suggest or design the ideal product for use with the solid they need to track.

A lower level of complexity in electronics and a higher quality transducer lead to a better sensor that is also more cost-effective. If a sensor is developed to enable users to record and visualize the ultrasonic waveforms, they can be used to find out if there are any reflecting objects that could trigger unwanted echoes or false alarms.

The potential to modify the detection thresholds enables users to account for and prevent unnecessary reflectors, and thus obtain more robust detection of targets in case of poor reflectivity or scattering that may be present with the solid material.

This aspect raises the overall consistency of the ultrasonic sensor and boosts the potential to obtain the required outcomes without the need to considerably derate the ultrasonic sensor.

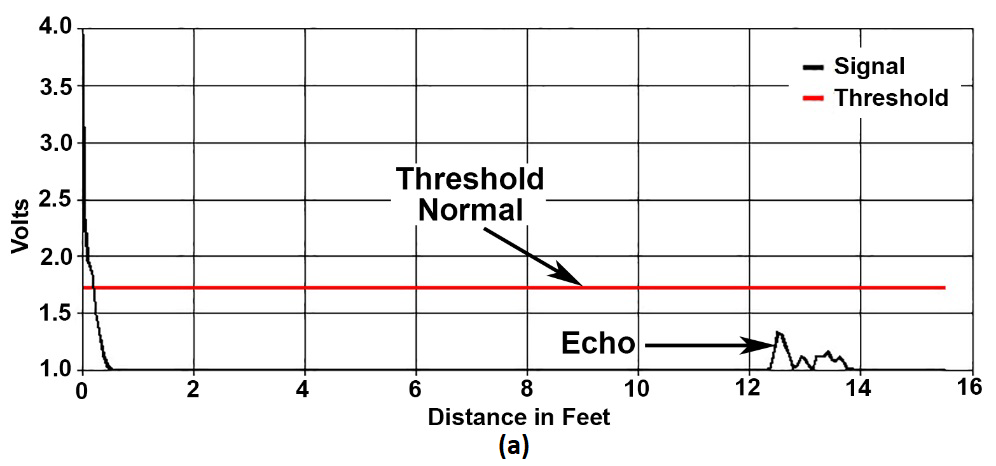

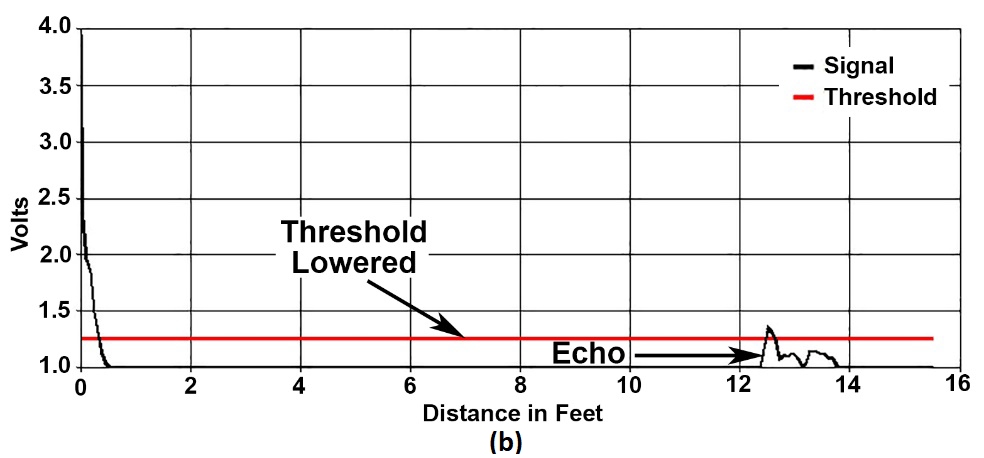

Waveform capture enables troubleshooting, which facilitates rapid, real-time assessments. Figures 2(a) and Figure 2(b) show how a target echo looks like when it is reflected from the surface of plastic pellets—a material that can scatter the sound. The waveforms demonstrate how the threshold of detection can be decreased to record a small echo without the presence of unusually high background noise.

- It is highly beneficial to use sensors that enable users to view a plot of the received echo versus range.

- Users can see if there is any peculiar electrical noise pick-up, ringing, or false targets.

- Thresholds are generally set higher to make sure that false echoes are not identified from potential ringing or electrical noise pickup that could take place in certain installations.

- A smaller echo from a poorer reflecting target, like solids, may still be above the background noise but will be below the “normal” target threshold detector.

- If a target is low due to poor reflectivity but is still above the electrical noise or background ringing for the installation, the threshold can be decreased to detect the echo.

Figure 2. (a) Ultrasonic waveform showing typically what occurs with scattering or poor reflectivity, echo strength is below the threshold. (b) Ultrasonic Waveform from a 95 kHz MassaSonic® PulStar® Plus Sensor with the Same Targets as in Figure 2(a), but with the detection threshold lowered to detect the target. Massa Products Corp.

Fabrication

Manufacturing is not a simple assembly but much more than that. To properly design high-quality and highly reliable sensors and transducers, it is crucial to have a high level of understanding, expertise, and skilled workmanship, and also cooperation between design engineering and production so that the best possible product is developed.

The facility must have high-quality procedures and controls in place. The production line should have the right processes, tools, and fixtures to regulate the manufacturing quality.

Highly qualified individuals should also be employed to build sophisticated instruments. They should be trained in the proper methods to construct, seal and test the ultrasonics. All these aspects will considerably decrease and even prevent the failure rate of the products.

Conclusion

Firstly, extensive knowledge in the design and development of electroacoustic transducers is the significant factor that influences the reliability and quality of an electroacoustic sensor. Secondly, it is crucial to ensure that the proper features of the sensor design correspond with the special chemical and physical challenges posed by the solid material.

This comprehensive understanding is required to optimize an electroacoustic sensor to work properly in caustic and challenging environments. Regular transducers are not as 'plug and play' as previously assumed.

All ultrasonics do not need to be derated by half for each solid measurement, and radar and other more costly alternatives may not be the ideal solution. The assumption is that they have singularly contributed to the common misconception that ultrasonic sensors are not reliable when employed in specific environments.

Midrange ultrasonics can be a practical, valid and value-added solution to users’ solid monitoring requirements. If a sensor and transducer are improved for the environment, then ultrasonic technology is an effective, low cost option for level measurement that will translate to a lower cost of ownership.

Massa Products Corporation designs, engineers, and produces all its systems and transducers in-house and has done so for more than seven decades. Massa’s design is fluid, right from conception through to production, and this is the case for systems, sensors and transducers employed in almost all environments.

Massa Products Corporation has the same quality controls in place for the sonar systems produced for the U.S. Navy in all commercial and industrial products. Some MassaSonic products utilized in industry and deployed in the 1980s are still operating in the field without any need for replacements.

The company has produced sophisticated sonar products utilized on the submarines that protect the U.S. people for many years with zero rejects.

This information has been sourced, reviewed and adapted from materials provided by Massa Products Corp.

For more information on this source, please visit Massa Products Corp.