In this interview, AZoSensors talks to Glen Ahearn and Arnaud Crastes from Teledyne Dalsa about infrared imaging, the current technology and recent advances.

What are some of the traditional applications of IR technology, and what technology was Teledyne Dalsa providing in this field?

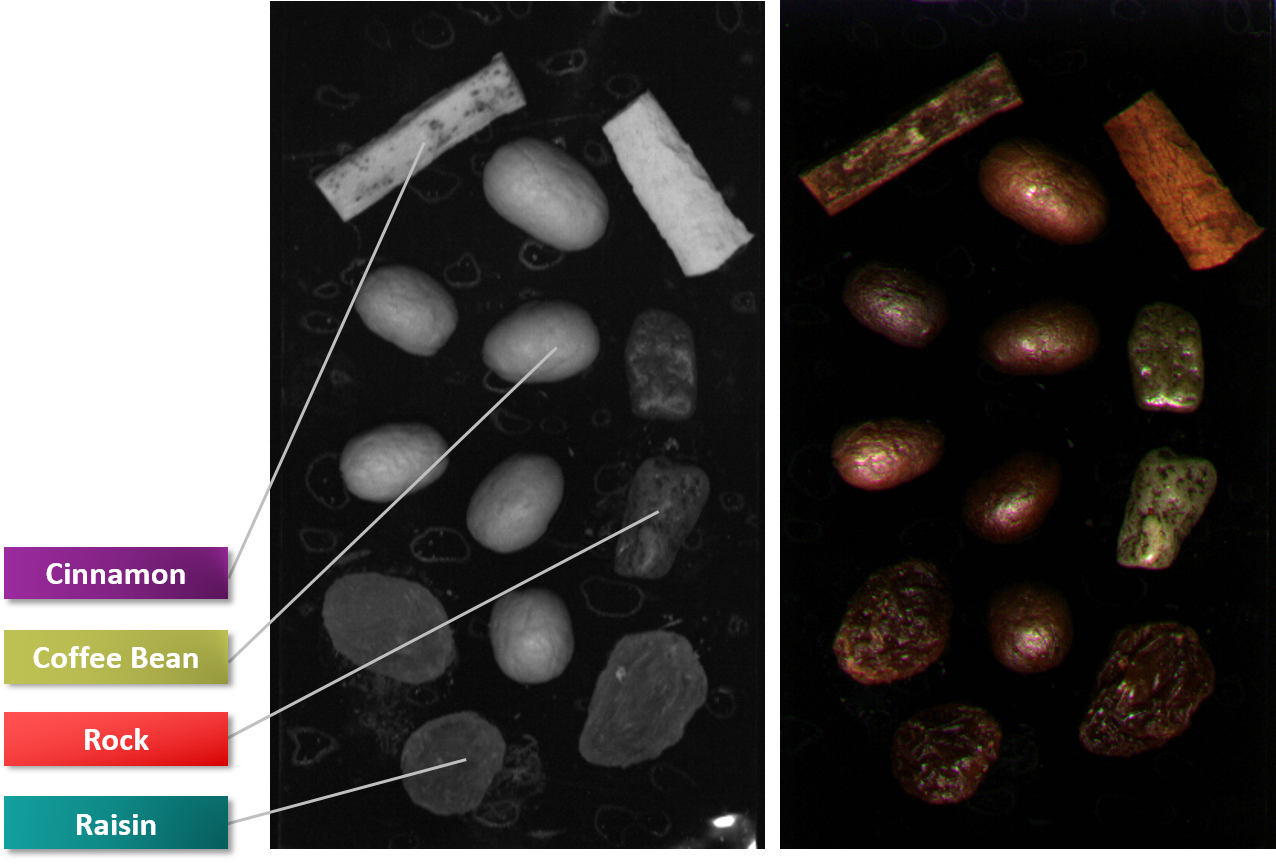

Some traditional applications using IR technology include food production and sorting, optical sorting, solar panel inspection, recycling, silicon wafer inspection, and general-purpose machine vision.

Recognizing that many of these applications are difficult to perform using visible light, Teledyne DALSA developed the Linea SWIR. The camera enables manufacturers to differentiate materials and detect moisture, as well as the ability to more easily identify foreign contaminants in their product stream.

Image credit: Teledyne Dalsa

What were some of the industries that were taking advantage of this tech, and how were they putting it to use?

Many industries are using SWIR technology, namely, solar panel manufacturers where SWIR can see through silicon to image the target on the back of the wafer. SWIR is able to identify defects, cracks, and saw marks inside or on opposite sides of the wafer as well as identify dead spots, weak areas, and weak cells.

Food sorting relies on SWIR to detect moisture, bruising and foreign objects. For example, determining apple quality is difficult with visible light which tends to stop at the skin of the fruit. SWIR can see water density and distribution more clearly inside the apple. This indicates key physical attributes that will help predict the measurable ‘quality’ of the apple, texture, water binding capacity, and specific gravity. The abnormalities in texture and density can indicate bruising, allowing the fruit to be caught and removed where there is less likelihood of waste.

Packaged goods are another industry that utilizes SWIR technology for fill level inspection in opaque bottles. SWIR is able to detect moisture content to determine if bottles are only half-filled. In addition, SWIR is used for pharmaceutical inspection to determine if blister packs have damaged or missing capsules.

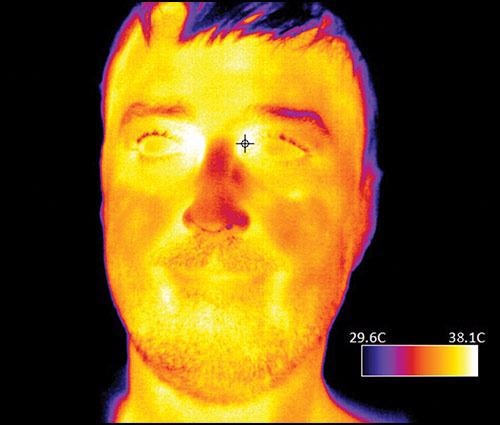

Why has thermal imaging become such an important technology during the COVID-19 pandemic?

IR thermography doesn’t require irradiation or expensive equipment and presents no health hazard. Infrared radiation emitted from our body can be detected, and with information about the ambient environment, used to estimate core body temperature and potentially detect who is running a fever.

Can you explain how this has created the need for new, more adaptable technology?

Detecting elevated skin temperature from a distance without physical contact has obvious advantages for both patients and practitioners – thus the rise in the use of spot meters and thermal cameras.

A full-face imaging approach using thermal (long-wave infrared) cameras has the potential to be more accurate (with many pixels on the canthus area for example), consistent, and thorough than a single-point sampling approach. A thermal image can include a temperature reference (from a black body radiator for example) in the scene for much higher accuracy and reliability, and an automated imaging system can free hands to do other temperature tasks. The speed of measurement is also a key advantage.

How have the needs of Teledyne’s customers changed in relation to these new challenges?

COVID-19 caused a spike in demand for high accuracy radiometric readings. Recently, advances in detector fabrication and lower costs have made LWIR imaging more accessible for consumer and industrial markets. This is clearly the best approach to a fever diagnostic.

Can you explain how Teledyne Dalsa is providing technology to meet these needs?

Our Calibir GXM uncooled LWIR cameras are ideally suited for industrial monitoring applications requiring radiometric measurements such as welding, sintering, baking, smelting, and firefighting. The automotive sector is the main user of sintered components, which are common in systems for transmission, engine, chassis, and exhaust. Other typical applications for temperature measurements can be found in food production, solar cell production, printed circuit board inspection, in the hot rolling of steel, in the testing of layer deposition in semiconductors, or in the inspection of shapes in response to temperature changes.

With an expanding customer base and businesses turning to thermal imaging that may never have taken advantage of it before, what challenges has this brought Teledyne Dalsa?

We saw more opportunities to expand our LWIR camera family by developing the MicroCalibir. This compact, low-power uncooled thermal camera platform features the smallest VGA IR core module on the market making it ideal for OEM drones, handhelds, helmet-mounted, and vehicular integration products.

Image credit: Teledyne Dalsa

What future changes do Teledyne Dalsa foresee within this market, and how will it approach these changes?

An extremely wide variety of industries worldwide are either moving towards or enhancing their existing use of thermal imaging technology for more efficient operations and processes. As such, we are also recognizing the need to address the diverse demand. We continue to see the future of thermal imaging expanding in defense and security, surveillance as well as in consumer and industrial markets.

Are there any pieces of equipment that Teledyne Dalsa is particularly proud of?

We are extremely proud of our infrared imaging product line for both SWIR and LWIR applications. The Linea SWIR GigE camera features a cutting-edge InGaAs sensor and uses SWIR light not visible to the human eye to handle challenging imaging applications by seeing and detecting what other technologies can’t. Our uncooled LWIR microbolometers, Calibir GX and MicroCalibir deliver outstanding thermal imaging performances, and enable us to meet the demands of a wide variety applications including defense, machine vision, firefighter security and surveillance, unmanned drones, environmental monitoring and most recently, detecting elevated skin temperature.

Can you explain how Teledyne Dalsa’s technology stays one step ahead in an ever-advancing field?

We look to the market and the voice of the customer to guide us in our infrared imaging solution development. We have the resources and ability to develop a wide variety of infrared solutions but being able to provide solutions that solve real problems (challenging problems) is our core goal.

As part of our development process, ease of use is key. We want to ensure that our customers can easily integrate our technology into their imaging systems. This means that everything needs to be as clear, intuitive, and logical as possible. This includes our camera design, software, documentation, support, and everywhere our customers interact with our products and our organization.

We also provide our customers with the flexibility to evolve with Teledyne DALSA as their systems needs and technology needs evolve. This means straightforward migrations to new sensors and even interface technology as needed.

About the interviewees

Glen Ahearn is a Sales and Application Support Manager at Teledyne DALSA. He has been in the vision industry for 38 years and has worked for companies that pioneered developments in the vision industry.

Arnaud Crastes is the Business Development Director at Teledyne Imaging Inc. Arnaud has more than 25 years of technology experience in program management, marketing and engineering in both visible and IR imaging system. He specializes in systems engineering, test and measurement of IR cameras and sensors, and modeling of system performance. He holds eight patents in ROIC architecture, lens and system design.

This information has been sourced, reviewed and adapted from materials provided by Teledyne DALSA.

For more information on this source, please visit Teledyne DALSA

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.