Ultrathin, lightweight, flexible, stretchable, and adherent are all common requirements for wearable sensor systems. They can also connect with human skin and accurately capture biomedical signals. With thousands of additional patents and hundreds of new firms and products, the wearable sensor market had grown to almost USD 10 billion by 2019.

Image Credit: Bignai/Shutterstock.com

Pressure and strain sensors have gotten a lot of interest recently because of their potential applications in next-generation human healthcare monitoring, such as motion sensors, machine interaction, soft robotics, and digital skin. Using pressure and strain sensors, external stimuli are converted to electrical signals such as resistance, flow, inductance, and voltage.

Wearable resistive pressure and strain sensors with piezoresistive properties should have compressible, foldable, and stretchable substrates as well as highly conductive materials. They should also have good sensitivity, quick reaction, a wide detection limit, skin tolerance, biocompatibility, and the ability to withstand many detection cycles.

Due to its flexibility and stretchability, silicone rubber polymers such as polydimethylsiloxane (PDMS) have been extensively used as pressure and strain sensor mediums. However, these materials do not meet all of the criteria, such as skin compatibility and the ability to be made from simple and renewable resources.

As a result, cellulosic materials, particularly nanocellulose, have emerged as a possible candidate for developing such sensors. Nanocellulose materials, on the other hand, must be tailored to include the necessary elements of a pressure and strain sensor.

Nanocellulose materials, for example, have limited electrical properties and some shapes have minimal compression or stretching resistance. Composites and 3D structures have been studied for the growth of advanced sensors to address these difficulties.

In this context, in a new study researchers discuss some of the prerequisites for fabricating nanocellulose 3D network structures (hydrogels and air-porous materials) that have properties that are useful for pressure and strain sensors. Recent improvements in cellulose-based pressure and strain sensors for human motion recognition are also discussed.

Discussion

Cellulose [(C6H10O5)n] is a homopolysaccharide containing a structural unit named cellobiose linked by β-(1-4) glycosidic bonds (β-D-glucan).

The initial concentration of nanocellulose influences the structure of air-porous materials and hydrogels. As a result, the higher the nanocellulose concentration, the larger the fiber interlacement and the smaller the ice crystal size, resulting in narrower holes.

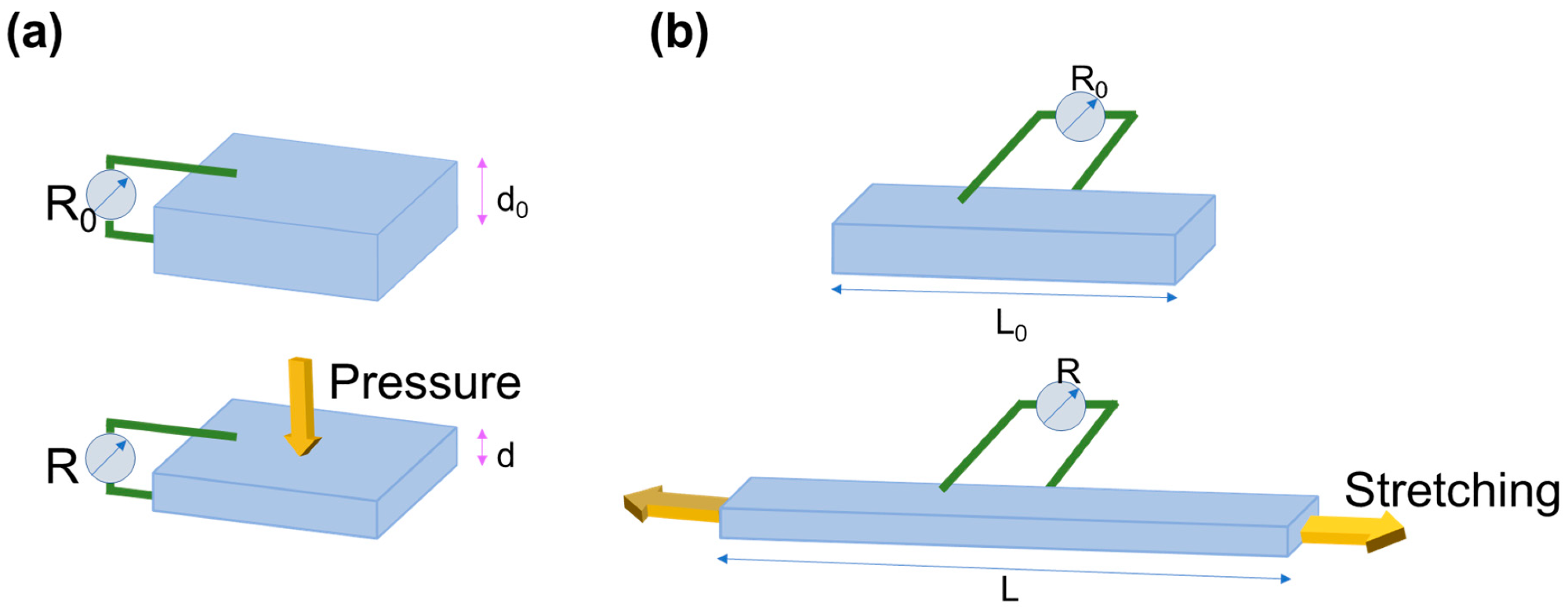

The electrical resistance changes in a material produced by structural deformation are termed piezoresistivity. The main functioning mechanism of a pressure sensor, as shown in Figure 4a, is based on the resistance change caused by the applied pressure. Resistance change, compression pressure, and sensitivity are three key performance characteristics of the sensor.

Figure 4. Schematic demonstration of working mechanism of (a) pressure sensor and (b) strain sensor. Image Credit: Basarir, et al., 2022

As shown in Figure 4b, the piezoresistive strain sensor’s operating principle is based on the sensor’s resistance changes as a result of the applied strain.

Directional freezing, freeze-drying, and carbonization were used to create the aerogel. Despite the fact that the BC fibers were totally converted to carbon during the carbonization process, they served as binding sites between the MXene sheets, resulting in a continuous and wave-shaped lamellar macrostructure.

The sensor had quick response times (167 milliseconds) and recuperation times (121 milliseconds), as well as the ability to identify facial emotions like puffing and smiling.

As a result, Zhai and colleagues created graphene-based highly sensitive sensors with waterborne polyurethane, cellulose nanocrystal, carbon nanotubes, and graphene to make use of the benefits of 2D nanomaterials. This air-porous material had pore diameters ranging from 110 to 180 μm with a three-dimensional lamellar structure.

Furthermore, this sensor demonstrated great mechanical performance, with just negligible damage after 800 cycles, as well as outstanding resistance response stability.

Researchers made carbonized bacterial nanocellulose (CBC) sheets and mixed them in with CNF suspensions. They then used directional ice-templating and freeze-drying to create CBC-CNF aerogels. The carbonized flakes were found to be spread across the CNF-based pore walls, and the aerogel had a porous structure with well-aligned channels. Ultimately, the sensor was employed to detect wrist and knee bending with success.

Figure 6a shows a macro view of a typical sensor containing 10% MWCNT. The addition of 10% MWCNT culminated in a homogeneous deposition of nanotubes on the cellulose fibers.

This cellulosic sponge sensor has excellent mechanical properties when put under pressure. The layered structure is crushed as the pressure applied to the sponge rises, and the electrical resistance is lowered as a result of the increased contact area of the conductive polypyrrole layer and possible enhanced electron transport pathways.

The finished hydrogel had compressible and elastic properties that were ideal for devices that required recovery. This hydrogel displayed quick, stable, and reversible activity when evaluated as a sensor applied to the index finger.

The actual current variations were explored by affixing the hydrogels to a finger and bending it at various angles, proving the sensor’s sensitivity to finger bending.

The resulting hydrogel is elastic and rebounds after the force is released.

Table 1 shows that the number of investigations and experiments using cellulosic materials for pressure sensors is still fairly restricted. However, this does not negate the importance of enhancing and developing this field. Performance, consistency, repeatability, and, most importantly, the sensitivity of such sensors must all be improved.

When compared to commercial sensors used in clinical applications, the pressure sensors perform better, especially in terms of sensitivity in the low-pressure area, as shown in Table 1.

Table 1. Properties of the pressure sensors prepared with cellulosic materials. Source: Basarir, et al., 2022

| Material Type |

Conductive

Material |

Cellulose

Type |

Sensitivity (kPa−1) |

Detection

Limit (kPa) |

Response

(ms) |

Recovery

(ms) |

Cyclic

Stability |

Human Body

Monitoring |

Ref. |

| Air-porous |

MXene |

Bacterial cellulose |

12.5 |

- |

167 |

121 |

100,000

(50% strain) |

Finger bending

Wrist bending

Elbow bending

Face expression

Arm pulse

Jugular venous pulse |

[39] |

| CNT/Graphene |

CNC |

0.25 |

0.112 |

- |

- |

- |

Finger bending

Wrist bending

Elbow bending

Squatting

Walking

Running |

[13] |

| Carbonized bacterial cellulose |

TEMPO CNF |

0.003–0.358 |

0.0025 |

50 |

110 |

10,000 |

Wrist bending

Knee bending

Finger touch

Breath blow |

[40] |

| Multiwalled carbon nanotube (MWCNT) |

Cotton balls |

0.0159–0.0197 |

- |

20 |

20 |

- |

Finger compression |

[14] |

| Polypyrrole |

Cellulose microcrystalline |

58.9 |

- |

- |

- |

10 |

- |

[41] |

| Hydrogel |

Lignin carbon |

CNF |

- |

- |

- |

- |

- |

Finger bending

Elbow bending

Palm gripping |

[42] |

| Silver nanoparticle |

TEMPO CNF |

9.5 |

- |

- |

- |

1000 |

Face expression

Elbow bending

Neck forward

Walking

Jumping |

[15] |

| MXene |

CNC |

- |

- |

- |

- |

- |

- |

[43] |

The researchers explain how cellulose may be used to make strain sensors. However, before researchers get started, it is indeed important to note that one of the key differences between pressure and strain sensors is how the external force is applied.

The BC nanofibers and MWCNTs entangle, with the MWCNTs adhering tightly to the BC surface, providing the aerogel with electrical characteristics. ΔR/R0 increased when stress was applied and then decreased when stress was released, which was linked to reducing and rising interparticle distances, accordingly.

The sensor has a gauge factor of 21 and a response time of 390 milliseconds. In fact, the sensor was mounted to a latex glove to monitor finger motions. When the finger was bent and unbent, resistance increased and decreased.

This hydrogel had high conductivity and the LED indicator lit, moreover, as the hydrogel was stretched from 0 to 300%, the light intensity of the LED gradually decreased.

The hydrogel sensor was also linked to the index finger, and the ΔR/R0 increased as the bending angle enhanced.

The frequency of resistance signals slowly increased upon stretching to 10%, 50%, 100%, and 150%, and the ΔR/R0 was nearly the same value under repeated stretching of each strain, implying the sensor’s repeatability and consistency.

The brightness of the diode bulb decreased with the increasing strain, implying the hydrogel’s conductivity. Furthermore, the ΔR/R0 gradually increased with stretching, and the resistance almost recovered to its initial value once the strain was released.

The resulting hydrogel sensor demonstrated good sensor performance, with fast and reversible response when the strain amount was changed.

The reduced elasticity of cellulosic materials makes them difficult to use as strain sensors, as evidenced by the lower number of research reports collected in Table 2. These could, however, be an opportunity for sensors that necessitate low strain adjustments to detect. Eventually, when comparing these sensors to commercial ones used in medical applications, researchers can see that they achieve a high degree of gauge factor.

Table 2. Properties of the strain sensors prepared with cellulosic materials. Source: Basarir, et al., 2022

| Material Type |

Conductive

Material |

Cellulose

Type |

Gauge

Factor |

Response

(ms) |

Cyclic

Stability |

Human Body

Monitoring |

Ref. |

| Air-porous |

Multiwalled

carbon nanotube (MWCNT) |

Bacterial cellulose |

21 |

390 |

1000 |

Finger bending |

[17] |

| Hydrogel |

Na+ Fe3+ |

Carboxymethyl cellulose |

1.99 (0–50%)

4.02 (50–600%) |

260 |

- |

Finger bending

Wrist bending

Elbow bending

Swallowing

Speaking |

[18] |

MWCNT

Carbon black |

Bacterial cellulose |

0.725 (0–60%)

2.216 (60–145.2%)

5.010 (145.2–200%) |

- |

- |

Wrist bending

Elbow bending |

[44] |

Carbonized

lignin |

CNF |

- |

- |

- |

Finger bending

Wrist bending

Elbow bending |

[42] |

| Zn2+ |

TEMPO CNF |

1.70 |

- |

500 |

Finger bending

Wrist bending

Elbow bending

Knee bending

Neck movement

Speaking |

[45] |

| Polyaniline |

Bacterial cellulose |

0.85 |

560 |

200 |

Finger bending

Wrist bending

Elbow bending

Knee bending |

[46] |

Conclusion

Researchers summarized the findings of pressure/strain sensors based on nanocellulose-based hydrogels and air-porous materials in this paper. It was proved how this extraordinary biomaterial could be tailored to produce sensors with excellent performance and sensitivity.

Researchers conclude, however, that the field is still in its early stages, with the major question being the optimization of microstructures and porosity of elastic materials with different functions for elevated sensors.

In conclusion, the comprehensive variety of different air-porous materials that can be fabricated from cellulose has yet to be explored—for example, sensors with optimized mechanical characteristics could cover wider pressure ranges.

Self-assembly of 2D nanomaterials with nanocellulose yielded impressive outcomes, particularly for air-porous pressure sensors—however, only a few studies have been conducted. As a result, more research into the impact of varying 2D nanomaterials and freezing conditions on sensory properties is required.

Overall, the design possibilities for skin-friendly/conformal and elevated wearable pressure/strain sensors for health care tracking based on various nanocellulose-based materials are massive and convincing.

Journal Reference

Basarir, F., Kaschuk, J. J., Vapaavuori, J. (2022) Perspective about Cellulose-Based Pressure and Strain Sensors for Human Motion Detection. Biosensors, 12(4), p. 187. Available Online: https://www.mdpi.com/2079-6374/12/4/187/htm.

Reference and Further Reading

- Sreenilayam, S.P., et al. (2020) dvanced materials of printed wearables for physiological parameter monitoring. Materials Today, 32, pp. 147–177. doi.org/10.1016/j.mattod.2019.08.005

- Nasiri, S & Khosravani, M R (2020) Progress and challenges in fabrication of wearable sensors for health monitoring. Sensors and Actuators A: Physical, 312, p. 112105. https://doi.org/10.1016/j.sna.2020.112105

- Mordor Intelligence (2020) Wearable Sensors Market-Growth, Trends, Covid-19 Impact, And Forecasts (2022–2027); Mortor Intelligence: Hyderabad, India.

- IDTechEx (2020) No Wearable Sensors 2018–2028: Technologies, Markets & PlayersTitle; IDTechEx: Cambridge, UK.

- Duan, L., et al. (2020) Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Progress in Materials Science, 114, p. 100617. doi.org/10.1016/j.pmatsci.2019.100617.

- Wang, X., et al. (2021) Research progress of flexible wearable pressure sensors. Sensors and Actuators A: Physical, 330, p. 112838. doi.org/10.1016/j.sna.2021.112838.

- Wang, X., et al. (2017) Flexible Sensing Electronics for Wearable/Attachable Health Monitoring. Small, 13, 1602790. doi.org/10.1002/smll.201602790.

- Trung, T Q & Lee, N -E (2016) Flexible and Stretchable Physical Sensor Integrated Platforms for Wearable Human-Activity Monitoring and Personal Healthcare. Advanced Materials, 28, pp. 4338–4372. https://doi.org/10.1002/adma.201504244.

- Nesser, H & Lubineau, G (2021) Strain Sensing by Electrical Capacitive Variation: From Stretchable Materials to Electronic Interfaces. Advanced Electronic Materials, 7, p. 2100190. doi.org/10.1002/aelm.202100190.

- Chen, J., et al. (2018) Polydimethylsiloxane (PDMS)-Based Flexible Resistive Strain Sensors for Wearable Applications. Applied Science, 8, p. 345. doi.org/10.3390/app8030345.

- Gao, Y., et al. (2021) Flexible and sensitive piezoresistive electronic skin based on TOCN/PPy hydrogel films. Journal of Applied Polymer Science, 138, p. 51367. doi.org/10.1002/app.51367.

- Fu, Q., et al. (2021) Emerging cellulose-derived materials: A promising platform for the design of flexible wearable sensors toward health and environment monitoring. Materials Chemistry Frontiers, 5, pp. 2051–2091. doi.org/10.1039/D0QM00748J.

- Zhai, J., et al. (2021) Flexible Waterborne Polyurethane/Cellulose Nanocrystal Composite Aerogels by Integrating Graphene and Carbon Nanotubes for a Highly Sensitive Pressure Sensor. ACS Sustainable Chemical Engineering, 9, pp. 14029–14039. doi.org/10.1021/acssuschemeng.1c03068.

- Zhang, H., et al. (2019) Flexible and Pressure-Responsive Sensors from Cellulose Fibers Coated with Multiwalled Carbon Nanotubes. ACS Applied Electronic Materials, 1, pp. 1179–1188. doi.org/10.1021/acsaelm.9b00182.

- Wang, S., et al. (2021) Skin-inspired nanofibrillated cellulose-reinforced hydrogels with high mechanical strength, long-term antibacterial, and self-recovery ability for wearable strain/pressure sensors. Carbohydrate Polymers, 261, p. 117894. doi.org/10.1016/j.carbpol.2021.117894.

- Chen, C., et al. (2020) Highly strong and flexible composite hydrogel reinforced by aligned wood cellulose skeleton via alkali treatment for muscle-like sensors. Chemical Engineering Journal, 400, p. 125876. doi.org/10.1016/j.cej.2020.125876.

- Hosseini, H., et al. (2018) Conductive bacterial cellulose/multiwall carbon nanotubes nanocomposite aerogel as a potentially flexible lightweight strain sensor. Carbohydrate Polymers, 201, pp. 228–235. doi.org/10.1016/j.carbpol.2018.08.054.

- Zhang, H., et al. (2020) Dual physically cross-linked carboxymethyl cellulose-based hydrogel with high stretchability and toughness as sensitive strain sensors. Cellulose, 27, pp. 9975–9989. doi.org/10.1007/s10570-020-03463-5.

- Brenes, R.G.R.., et al. (2021) Production and Processing for Biomedical Applications. ChemNanoMat. doi.org/10.1002/cnma.202100329.

- Mali, P & Sherje, A P (2022) Cellulose nanocrystals: Fundamentals and biomedical applications. Carbohydrate Polymers, 275, p. 118668. doi.org/10.1016/j.carbpol.2021.118668.

- Divya., et al. (2021) Nanobioengineered Sensing Technologies Based on Cellulose Matrices for Detection of Small Molecules, Macromolecules, and Cells. Biosensors, 11, p. 168. doi.org/10.3390/bios11060168.

- Li, T., et al. (2021) Developing fibrillated cellulose as a sustainable technological material. Nature, 590, pp. 47–56. doi.org/10.1038/s41586-020-03167-7.

- Wang, L., et al. (2021) Review on Nonconventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications. Biomacromolecules, 22, pp. 4037–4059. doi.org/10.1021/acs.biomac.1c00640.

- Larsson, P.A., et al. (2019) Towards optimised size distribution in commercial microfibrillated cellulose: A fractionation approach. Cellulose, 26, pp. 1565–1575. doi.org/10.1007/s10570-018-2214-4.

- Yi, T., et al. (2020) From Cellulose to Cellulose Nanofibrils—A Comprehensive Review of the Preparation and Modification of Cellulose Nanofibrils. Materials, (Basel), 13, p. 5062. doi.org/10.3390/ma13225062.

- Serra-Parareda, F., et al. (2021) Tuning morphology and structure of non-woody nanocellulose: Ranging between nanofibers and nanocrystals. Industrial Crops and Products, 171, p. 113877. doi.org/10.1016/j.indcrop.2021.113877.

- Wahid, F., et al. (2021) Bacterial cellulose and its potential for biomedical applications. Biotechnology Advances, 53, p. 107856. doi.org/10.1016/j.biotechadv.2021.107856.

- Mokhena, T C & John, M J (2020) Cellulose nanomaterials: New generation materials for solving global issues. Cellulose, 27, pp. 1149–1194. doi.org/10.1007/s10570-019-02889-w.

- Zhong, C., et al. (2020) Industrial-Scale Production and Applications of Bacterial Cellulose. Frontiers in Bioengineering and Biotechnology, 8, p. 1425. doi.org/10.3389/fbioe.2020.605374.

- Wei, Z., et al. (2021) Nanocellulose based hydrogel or aerogel scaffolds for tissue engineering. Cellulose, 28, pp. 7497–7520. doi.org/10.1007/s10570-021-04021-3.

- De France, K. J., et al. (2017) Review of Hydrogels and Aerogels Containing Nanocellulose. Chemistry of Materials, 29, pp. 4609–4631. https://doi.org/10.1021/acs.chemmater.7b00531.

- Sun, Y., et al. (2021) Nanocellulose-based lightweight porous materials: A review. Carbohydrate Polymers, 255, p. 117489. doi.org/10.1016/j.carbpol.2020.117489.

- Huang, D., et al. (2020) Effect of Partial Dehydration on Freeze-Drying of Aqueous Nanocellulose Suspension. ACS Sustainable Chemistry Engineering, 8, pp. 1389–11395. doi.org/10.1021/acssuschemeng.0c03688.

- Ganesan, K., et al. (2019) Influence of hierarchical porous structures on the mechanical properties of cellulose aerogels. Journal of Sol-Gel Science and Technology, 89, pp. 156–165. doi.org/10.1007/s10971-018-4828-2.

- Isobe, N., et al. (2018) Cellulose hydrogel with tunable shape and mechanical properties: From rigid cylinder to soft scaffold. International Journal of Biological Macromolecules, 117, pp. 625–631. doi.org/10.1016/j.ijbiomac.2018.05.071.

- Zhang, T., et al. (2018) Characterization of the nano-cellulose aerogel from mixing CNF and CNC with different ratio. Materials Letters, 229, pp. 103–106. doi.org/10.1016/j.matlet.2018.06.101.

- Teodoro, K.B.R., et al. (2021) A Review on the Role and Performance of Cellulose Nanomaterials in Sensors. ACS Sensors, 6, pp. 2473–2496. doi.org/10.1021/acssensors.1c00473.

- Wang, C., et al. (2019) Directional Strain Sensor Based on Anisotropic Microhoneycomb Cellulose Nanofiber-Carbon Nanotube Hybrid Aerogels Prepared by Unidirectional Freeze Drying. Small, 15, p. 1805363. doi.org/10.1002/smll.201805363.

- Chen, Z., et al. (2019) Compressible, Elastic, and Pressure-Sensitive Carbon Aerogels Derived from 2D Titanium Carbide Nanosheets and Bacterial Cellulose for Wearable Sensors. Chemistry of Materials, 31, pp. 3301–3312. doi.org/10.1021/acs.chemmater.9b00259.

- Chen, S., et al. (2021) Flexible and Sensitivity-Adjustable Pressure Sensors Based on Carbonized Bacterial Nanocellulose/Wood-Derived Cellulose Nanofibril Composite Aerogels. ACS Applied Materials Interfaces, 13, pp. 8754–8763. doi.org/10.1021/acsami.0c21392.

- Luo, M., et al. (2017) In-situ polymerization of PPy/cellulose composite sponge with high elasticity and conductivity for the application of pressure sensor. Composites Communications, 6, pp. 68–72. https://doi.org/10.1016/j.coco.2017.10.001.

- Li, M., et al. (2021) Flexible conductive hydrogel fabricated with polyvinyl alcohol, carboxymethyl chitosan, cellulose nanofibrils, and lignin-based carbon applied as strain and pressure sensor. International Journal of Biological Macromolecules, 166, pp. 1526–1534. doi.org/10.1016/j.ijbiomac.2020.11.032.

- Pi, M., et al. (2021) Robust and ultrasensitive hydrogel sensors enhanced by MXene/cellulose nanocrystals. Journal of Materials Science, 56, pp. 8871–8886. https://doi.org/10.1007/s10853-020-05644-w.

- Huang, J., et al. (2020) A Dual-Mode Wearable Sensor Based on Bacterial Cellulose Reinforced Hydrogels for Highly Sensitive Strain/Pressure Sensing. Advanced Electronic Materials, 6, p. 1900934. doi.org/10.1002/aelm.201900934.

- Hu, J., et al. (2022) One-pot freezing-thawing preparation of cellulose nanofibrils reinforced polyvinyl alcohol based ionic hydrogel strain sensor for human motion monitoring. Carbohydrate Polymers, 275, p. 118697. doi.org/10.1016/j.carbpol.2021.118697.

- Qin, H., et al. (2021) Bacterial Cellulose Reinforced Polyaniline Electroconductive Hydrogel with Multiple Weak H-Bonds as Flexible and Sensitive Strain Sensor. Macromolecular Materials and Engineering, 306, p. 2100159. doi.org/10.1002/mame.202100159.