The rise in popularity and uptake of electric vehicles cannot simply be put into words; one has to look at the data. Research carried out by the International Council on Clean Transportation (ICCT) in 2017 determined that global annual electric vehicle sales were increasing nearly at an exponential rate.1

Image credit: Merit Sensor Systems

By the end of 2020, more than 10 million electric cars were navigating roads across the world.2

Electric vehicles are appealing to buyers for many reasons: they produce fewer emissions, can be operated at significantly lower costs and offer improved long-term prospects compared to gasoline-fueled cars.3–5

However, one of the greatest challenges in getting more people to convert to electric vehicles has long been the limited range that they can travel on a single charge.6 However, this obstacle is steadily being overcome.

Incremental improvements in battery technology are on the rise, and the maximum range of electric vehicles is extended with each advance, making electric vehicle ownership a more viable option for a future generation of drivers.

The Importance of Cooling Systems in Electric Vehicles

Attempts at improving battery capacity, however, can present certain challenges. The main question is related to cooling. Batteries generate heat when they charge and discharge. Therefore, the more energy a battery stores and the more quickly it charges or discharges, the more heat it will tend to create.

Vehicles that are entirely electric are equipped with a cooling system that maintains particular temperature limits in the vehicle’s power electronics and battery packs. The main role of the cooling system is to ensure that the battery temperature remains within safe operating limits.

If the lithium-ion battery pack’s temperature in any given cell gets too hot, it can provoke a chain reaction known as thermal runaway, in which the complete battery pack experiences catastrophic exothermic decomposition.7

Preventing overheating and thermal runaway is, of course, critical. The majority of EV cooling systems aim to keep battery packs at their optimum operating temperature most of the time.

Usually, this means a close-to-uniform temperature distribution in the 15 - 35 °C range.8 If temperatures are allowed to significantly vary throughout the pack or fall outside this particular range, then charging times and efficiency can be negatively affected resulting in a reduction in the service life of the battery.

EV Cooling Technologies

Electric vehicles employ various cooling technologies to manage the temperature of power systems: air, fins and liquid cooling.

Fin cooling is a simple and economical passive cooling mechanism that has been demonstrated to be successful in the world of electronics.

Effectively, building power-intensive components to feature fins and ridges as opposed to flat faces increases their surface area, thereby improving the rate at which they can dissipate heat to their surroundings.

However, fins have limited application in electric vehicles as they can increase the weight of power systems significantly.

Air cooling, the circulation of relatively cool air across the surface of a hot object, is another comparatively simple technology as it will cool it down more rapidly.

Air cooling is typically cost-effective and has been employed in some electric car models (including early models of the Nissan Leaf). However, this system can be relatively energy-intensive, and cars that are dependent on air cooling can run into trouble in hot weather.8

Liquid cooling is the most efficient way of controlling the temperature of batteries and power systems in electric vehicles.

Piping liquid coolant throughout power systems facilitates effective heat removal and while it is comparatively expensive and complex, it offers more precise temperature control of electronic systems and battery packs in electric vehicles.

As manufacturers are driving towards installing increasingly higher capacity battery packs in electric vehicles, the demands that these cooling systems must be able to cope with are also increasing.

Liquid cooling systems are becoming more crucial and complex as charging rates and battery capacity increase.9,10 Liquid cooling systems in today’s electric vehicles may necessitate subdivision of the cooling system into several circuits and heat exchange between battery coolant and A/C system refrigerant.

The Role of Pressure Sensors in EV Cooling Systems

Pressure is a key parameter in an electric vehicle’s liquid cooling system. Pressure sensors are vital components both for feedback for cooling system regulation and optimization as well as being able to detect pressure loss that could suggest a leak.

As liquid cooling systems grow in complexity, the demand for accurate and robust pressure sensors for EV cooling systems is now greater than any time before.

Merit Sensor Systems designs and manufactures a wide range of high-performance pressure sensors appropriate for demanding EV applications. The TR series sensors have been developed to offer precise pressure measurements in harsh media such as gases, oils and refrigerants.

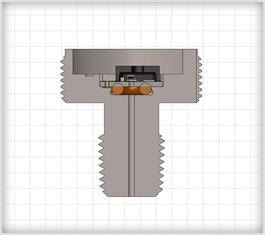

TR series pressure sensors incorporate a hermetically sealed die that is able to take pressure measurements from the backside, where the media only comes into contact with the ceramic substrate, glass and gold-tin eutectic solder.

TR series sensors also offer accurate, dependable and robust pressure sensing in complex EV fluid system applications while rated for temperatures from -40 °C to 150 °C.

Figure 1. TR-Series face sealing integration (MeriTrek starter Kit) into metal/plastic housing. Image Credit: Merit Sensor

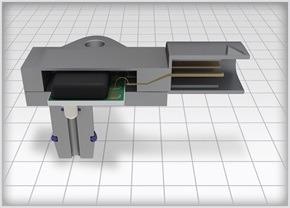

TVC series sensors have been optimized for measuring mid-to-high pressures in refrigerant gases up to 2,000 kPa.

Mounting the silicon die sensing element at the top of a ceramic pressure port means the TVC sensors have the capacity to measure backside pressure while separating the media from internal electronics, offering reliable and robust pressure (burst pressure 5x) measurements over a prolonged service life, even in harsh media.

Figure 2. TVC-Series easy integration in metal/plastic housing with radial sealing (o-ring). Image Credit: Merit Sensor

With simple sealing and electrical connections, TR and TVC series pressure sensors have been engineered for seamless integration into complex fluid system pipelines and rapid connectors owing to reliable face and radial sealing.

To discover more, contact Merit Sensor Systems and find out how its pressure sensors offer a series of unparalleled advantages in EV systems.

References

- Lutsey, N. & Nicholas, M. Update on electric vehicle costs in the United States through 2030. (2019).

- Global EV Outlook 2021 – Analysis. IEA https://www.iea.org/reports/global-ev-outlook-2021.

- How green are electric cars? | Environment | The Guardian.

- Running Costs of EVs: How much it costs to buy and run an electric car | OVO Energy. https://www.ovoenergy.com/guides/energy-guides/how-much-does-it-cost-to-charge-and-run-an-electric-car.html, https://www.ovoenergy.com/guides/energy-guides/how-much-does-it-cost-to-charge-and-run-an-electric-car.html.

- How long before we run out of fossil fuels? Our World in Data https://ourworldindata.org/how-long-before-we-run-out-of-fossil-fuels.

- The real barriers to electric vehicle adoption. MIT Sloan https://mitsloan.mit.edu/ideas-made-to-matter/real-barriers-to-electric-vehicle-adoption.

- Feng, X., Ren, D., He, X. & Ouyang, M. Mitigating Thermal Runaway of Lithium-Ion Batteries. Joule 4, 743–770 (2020).

- Chen, D., Jiang, J., Kim, G.-H., Yang, C. & Pesaran, A. Comparison of different cooling methods for lithium ion battery cells. Applied Thermal Engineering 94, 846–854 (2016).

- Design of Direct and Indirect Liquid Cooling Systems for High-Capacity, High-Power Lithium-Ion Battery Packs on JSTOR. https://www.jstor.org/stable/26169002.

This information has been sourced, reviewed and adapted from materials provided by Merit Sensor.

For more information on this source, please visit Merit Sensor.