AZoSensors speaks with Anna Maria Coclite from TU Graz about her research into a material with multisensory characteristics that make it a thousand times more sensitive than human skin. This novel skin-like hybrid material has numerous fields of application, for instance, in the healthcare sector.

In your research, you describe a material with multisensory characteristics as a ‘holy grail’ in the technology of intelligent artificial materials. Why is this, and what inspired you to try and develop such an integral material?

A multisensory material is a material that responds to several stimuli by changing its characteristics. This makes it highly adaptable to the environment and very versatile, as it can then be used for several applications; as a sensor for artificial/electronic skins or within wearable electronics, as an actuator for soft robotics, etc.

Nature is full of examples of integrated materials, e.g., in our body, but also within plants. The skin of humans and animals is a fascinating ensemble of several materials and mechanisms that work together to perform several functions: protection, sensing and thermal regulation, to just name a few. The challenge of recreating/improving such an integrated system - artificially - is what inspired my research.

Can you provide an overview of the innovative process you and your team used to develop your advanced electronic skin?

Other examples of electronic skins are based on layer systems, where the sensing material is a homogeneous horizontal foil between the electrodes. This type of architecture leads to a low lateral resolution in the sensors, as the stimuli location cannot be determined with very high precision.

The precision or lateral resolution of human skin is 1 mm2.

We instead developed vertical sensing rods with a diameter of 500 nm that sense independently from one another. This allowed us to achieve unprecedented lateral resolution, a thousand times smaller than the resolution of human skin in a fingertip.

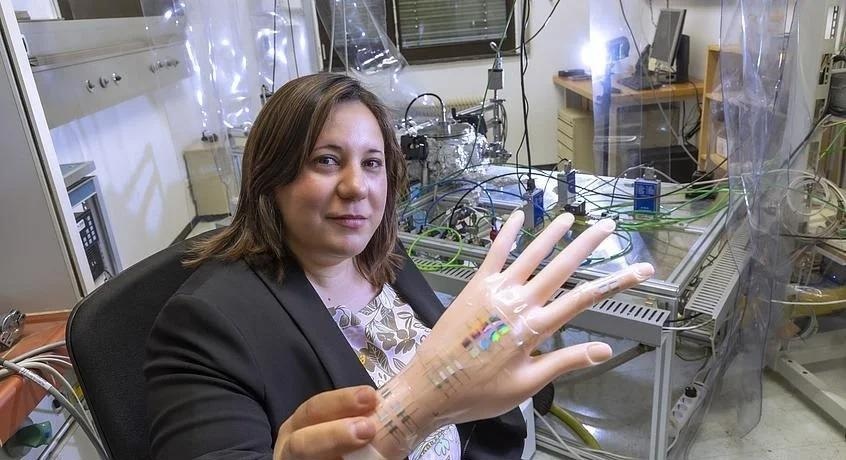

Image Credit: Lunghammer - TU Graz

To create the vertical rods, we used a template with some wells, and we filled them with our sensing material. The method used is called chemical vapor deposition. The sensing material was synthesized and transferred to the template from the vapor phase. We chose to use vapors to coat the wells of the template conformally so that the sensing material would adhere to both the vertical and horizontal walls of the wells instead of filling them from the bottom up, as it would have happened if one had used a liquid.

Your hybrid material is even more sensitive than a human fingertip. What are the multisensory characteristics that this three-in-one hybrid material is able to sense?

The material senses temperature, humidity and pressure, but the advancement compared to the human fingertip is not to do with what is sensed but rather the precision with which it senses. The stimuli can be detected with a precision that is a thousand times higher than human skin. This could detect, for example, much smaller objects that the human touch does not feel.

How does the novel material work? How is it able to sense changes in temperature, pressure, and humidity?

The hybrid material is made of a core that depending on temperature and humidity, expands or shrinks. The shell of the hybrid material is made of piezoelectric zinc oxide. When the core expands, it deforms the piezo, which then produces an electrical signal.

The changes in pressure, for example, a touch, are sensed directly by the piezoelectric shell of zinc oxide. The electric signals produced by temperature, humidity and pressure are then measured by electrodes forming pixels, similar to a TV.

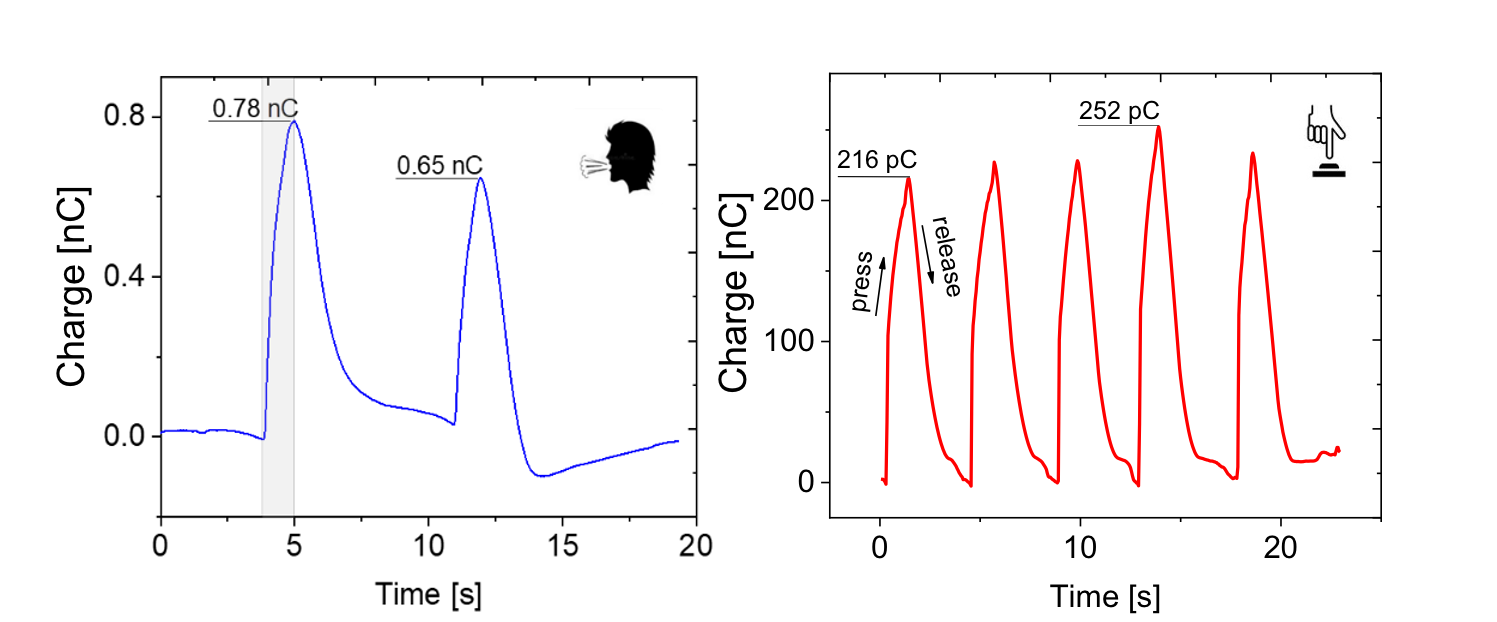

How did you test the efficacy of your material, and what did you discover?

We exposed the devices to different humidity, temperature and pressure stimuli, from very small to very large. So far, we have a response when the relative humidity is higher than 70%, the temperature is sensed between 30 °C and 50 °C, and force up to 20 N (more or less the force applied by a strong touch) can be detected.

Image Credit: TU Graz

How does this material compare to conventional sensors?

There are no standard ways of comparing conventional sensors with laboratory-scale developed ones. For humidity, we have seen a three-fold improvement in sensing speed. For the other stimuli, the sensing speed is very dependent on how fast the stimulus itself is applied.

The lateral resolution is much higher than in other sensors as a minimum area of 2 mm2 can be sensed by conventional sensors, while ours can sense an area of 0.25 mm2.

Our devices are also much thinner than conventional sensors.

What are the potential fields of application for this skin-like hybrid material? What industries would benefit from this novel material and why?

Industries working on robotics or prostheses could benefit from this skin-like device since it could be used to gain sensory information. On the other hand, also industries working on integrating sensors in miniaturized devices (e.g., watches, textiles, glasses) could also benefit from this material.

For example, the integration of such sensors in a smartwatch could give precise information on skin hydration. Embedding such materials in textiles could be used to detect very tiny objects (e.g., bacteria) approaching the human body.

After the success of your initial study, what are the next steps for your research?

We are working on making the material even thinner and more flexible, with an extended temperature range. We are also testing the stability for extended cycles of stimuli exposure

When it comes to upscaling the production of the material, what equipment would you need, who would provide it, and what partners do you hope to accompany you on this journey?

The equipment we used for the production of the material, for the chemical vapor deposition process mentioned before, is actually the one that is currently used for integrated circuits, transistors, and packaging. The involvement of companies that already have the equipment available would definitely help the upscaling of the production of such material.

About Anna Maria Coclite

Anna Maria Coclite has been an Associate Professor in the Institute of Solid State Physics of the Graz University of Technology since January 2018, after being Assistant Professor at the same institution since 2013. From 2010 to 2013, she was a postdoctoral associate at the Massachusetts Institute of Technology. She received her Ph.D. degree in Chemical Science from the University of Bari, Italy, in 2010.

Anna Maria Coclite has been an Associate Professor in the Institute of Solid State Physics of the Graz University of Technology since January 2018, after being Assistant Professor at the same institution since 2013. From 2010 to 2013, she was a postdoctoral associate at the Massachusetts Institute of Technology. She received her Ph.D. degree in Chemical Science from the University of Bari, Italy, in 2010.

She is the co-leader of the “Advanced Material Science” inter-faculty Field of Expertise at TU Graz since 2020. Her research interests focus on materials science and advanced methods for thin film growth, including thin film technologies, nanomaterials, and surface chemistry. In 2016, she won the prestigious European Research Council (ERC) Starting grant to fund her research on “Smart Core-shell sensor arrays for artificial skins.”

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.