VEGA is revolutionizing radar level measurement with the VEGAPULS 6X. The following briefly lists the instrument’s significant benefits:

- Fast configuration

- Simple commissioning and setup

- Highest standards of security

- Easy operation

Video Credit: VEGA Grieshaber KG

Deciding on an Instrument is No Longer Complicated

VEGA, a leading manufacturer of switching, level, and pressure instrumentation, has created a radar sensor that is ideal for all applications: VEGAPULS 6X.

One for all

No matter whether in liquids or bulk solids, or under challenging circumstances, such as high temperature, dust, or intense pressure, VEGAPULS 6X gives exact measurement results.

Confined areas, caustic substances, such as chlorine, humidity, and deposits on the sensor have no impact on the measurement outcome.

The instrument is always ideal for the task at hand: The configurator makes it simple for users to quickly put together a sensor that meets their unique requirements with a few mouse clicks. They do not have to be concerned about factors, such as operating frequency, a sufficient connection, or the medium’s DK value.

The setup and commissioning are simple: The sensor can be set up such that it only has to be placed and electrically connected if all the application’s specifics are understood.

What About Safety Considerations?

Image Credit: VEGA Grieshaber KG

A thorough safety concept is included with this radar sensor for continuous level measurements. The SIL-certified sensor lowers the risks in safety-critical applications due to its high operational dependability and safety qualities.

It also complies with IEC 62443’s stringent requirements in terms of cybersecurity. The new radar chip created by VEGA makes all of this feasible.

How Does Communication Work?

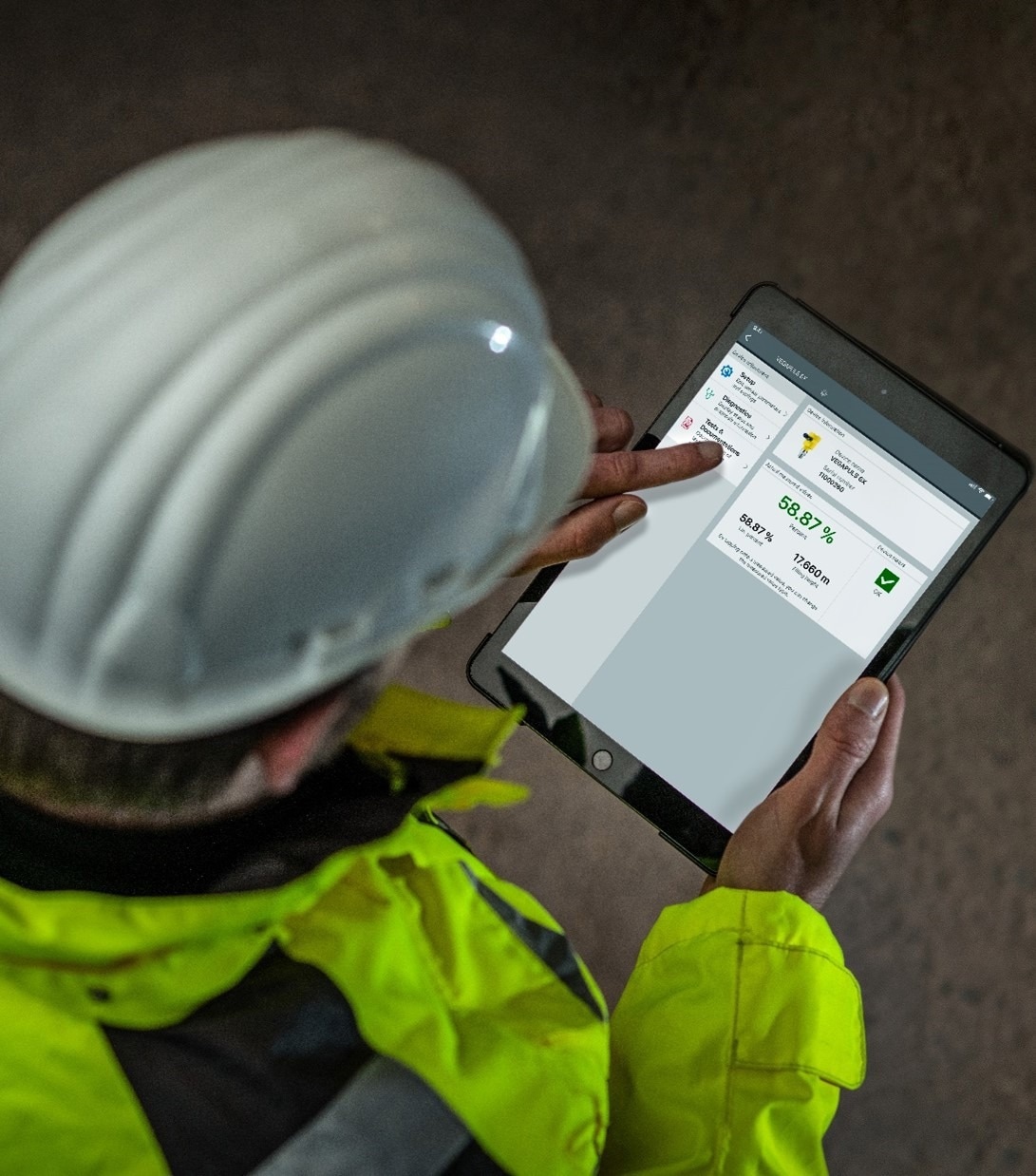

The instrument can be adjusted in a number of different ways. The proven PLICSCOM display and adjustment module, whose menu layout is intended to be easy to understand, has been given by VEGA for sensor adjustment directly at the measuring point.

Image Credit: VEGA Grieshaber KG

A PC or laptop running PACTware can also be utilized to change the level sensor. A wireless adjustment option via Bluetooth on a smartphone or tablet is provided by the VEGA Tools App.

- The most important technical data:

- Process temperature: –196° to 450° C

- Process pressure: –1 to +160 bar

- Measuring range: 120 meters

- Measuring accuracy: +/–1 millimeter

Video Credit: VEGA Grieshaber KG

VEGAPULS 6X: The Ideal Radar Sensor for Level Measurement

The sensor is the result of more than 30 years of expertise in the field of radar measurement technology. More than a million radar sensors that are currently in use globally in chemicals, energy, food, oil, and gas, among many others.

The VEGAPULS 61, 62, 63, 64, 65, 66, 67, 68, and VEGAPULS 69 sensors that came before it, which operated at 80 GHz, 26 GHz, and 6 GHz, are all combined into a single instrument. No matter the process circumstances, VEGAPULS 6X provides precise measurement results and, owing to the non-contact measuring approach offers maintenance-free operation.

Related Applications

Chlorine storage tank

Level measurement and point level detection in storage tanks for chlorine

The chemical and diffusion resistance of the materials in the manufacturing equipment is put under a lot of stress during the synthesis and storage of chlorine. When choosing sealing materials, extensive process expertise and experience are needed.

It is crucial to the long-term, secure and successful functioning of the facility. The instrumentation’s dependability is of utmost importance since operations can only be stopped with significant expense and plant disruption.

Image Credit: VEGA Grieshaber KG

- Measuring task

- Level measurement and point level detection

- Measuring point

- Measuring range up to

- Medium

- Process temperature

- Process pressure

- Special challenges

- Very aggressive medium with a strong tendency to diffuse

- Reliable

- All materials are fully chemically resistant

- Cost effective

- Universal application, independent of product characteristics and process conditions

- User-friendly

- Maintenance-free operation

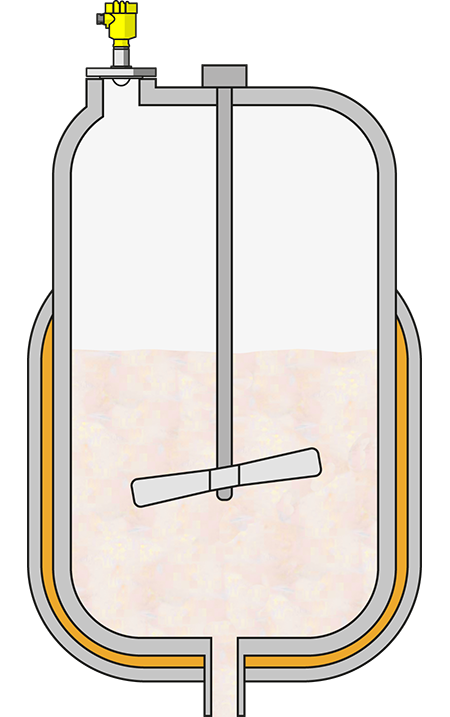

Reactor

Level ,easurement in an aluminum powder suspension reactor

An intermediary step in the manufacturing of titanium sponges is aluminum powder suspension. The suspension of aluminum powder undergoes the removal of vanadium oxide trichloride in the reactor.

On the product surface, there is intense turbulence when the suspension of aluminum powder is supplied into the reactor. The level in the reactor has to be precisely measured and monitored to optimize the process.

Image Credit: VEGA Grieshaber KG

- Measuring task

- Measuring point

- Measuring range up to

- Medium

- Aluminum powder suspension

- Process temperature

- Process pressure

- Special challenges

- Low dielectric constant, confined spaces, strong turbulence on the product surface, condensation

- Reliable

- Reliable measurement despite small dielectric constants

- Cost effective

- Reliable measurement of the entire reactor volume

- User friendly

- Simple mounting and setup

This information has been sourced, reviewed and adapted from materials provided by VEGA Grieshaber KG.

For more information on this source, please visit VEGA Grieshaber KG.