VCAs are increasingly becoming a valuable solution for various precision motion applications. The demand for smaller and higher accuracy linear motion control components has been rising, expanding the range of applications where these actuators are utilized.

They are employed in a growing number of mission-critical equipment, including ventilators used to assist patients in breathing and guiding the arms of spacecraft designed to collect asteroids.

Voice coil actuation (VCA) technology was initially designed for use in audio speakers. However, in recent years it has found its way into a wide range of applications, including medical, industrial process, and space applications, due to its ability to provide precise and reliable motion control.

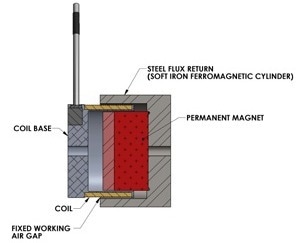

While VCA technology (depicted in Figure 1) has been around for decades, it has remained a mystery to many design engineers, mainly because its application spaces were previously quite limited.

As a result, many designers had to rely on less flexible solenoid-based devices. However, with the advent of powerful microcontrollers and efficient drivers, implementing advanced linear motion designs using VCAs has become more accessible and cost-effective.

When an engineer develops a product that necessitates highly reliable, repeatable, and controllable motion control, it is advisable to consider using voice coil actuators (VCA). This type of actuator provides a multitude of advantages to the engineer.

VCAs are simple and robust yet capable of achieving exact precision as per the input. VCAs accelerate smoothly and quickly to any position within their stroke with minimal hysteresis, limited only by the system's position-sensing precision and driver capability.

These qualities make VCAs ideal for medical devices, robotics, and industrial process equipment applications.

Figure 1. Linear Voice Coil Actuator. Used in a wide range of medical and industrial applications, an axial voice coil actuator is composed of a permanent magnet within a moving tubular coil of wire, inside a ferromagnetic cylinder. When current runs through the coil, it becomes magnetized and repels against the magnets, producing an in-and-out, back-and-forth motion. Image Credit: Sensata Technologies, Inc.

Staying Alive - Precision Control in Medical Devices

The medical industry is an application area that requires the utmost precision. Medical devices, such as drug-dispensing pumps and ventilators, require accurate measurement and management of every microliter of liquid or air.

To achieve this, a VCA-based solution provides precise motion control in medical flow-management systems, increasing accuracy without added complexity or bulk.

The challenges of designing medical devices extend beyond strict performance and regulatory standards, including the need for small, lightweight devices that allow for portable use by caregivers moving between rooms in a facility.

The demand for optimal performance in a limited space makes a VCA solution ideal. In particular, linear voice coil actuators can be designed to meet the ultra-small size and exacting motion control requirements essential in the medical industry.

These miniature VCAs are often utilized to control ventilators' inhalation and exhalation valves, providing the required air and necessary reliability for life-critical applications (as shown in Figure 2).

Figure 2. VCAs such as Sensata’s LAH08-15-000A are often used to control inhalation and exhalation valves on ventilators as their precision, reliability, and small size meet the demands of life-critical applications in the medical industry. Image Credit: Sensata Technologies, Inc.

One of the benefits of utilizing VCA motors is their ability to operate in both directions, as well as the presence of permanent magnets and magnetic latches.

These features allow the VCA to remain in a fixed position at either end of a stroke in the event of a power outage, ensuring valves remain either open or closed during disruptive power situations.

These compact VCAs have a diameter of only 0.75 inches and a weight of 2.3 ounces, yet can deliver a peak force of almost two pounds during an operating stroke of ±2 mm with low hysteresis, zero cogging, high acceleration, and long cycle life.

This precise linear motion control is also suitable for other precision medical systems, such as anesthesia machines, ultrasound probes, blood analyzers, and laboratory equipment.

Like the medical industry, military and aerospace equipment demand precise operation in various environmental conditions, making it imperative for the equipment to be rugged and accurate.

In such cases, custom solutions may be necessary to ensure that all performance specifications are considered during the initial equipment design.

Fail-Safe Operation on Spacecraft

Sensata's engineers developed a customized moving magnet VCA to meet the harsh requirements of a spectrometer moving mirror on the OSIRIS-Rex spacecraft.

Launched in 2016, this spacecraft was designed to reach Asteroid Bennu by 2018 and return samples to Earth by 2023.

The customized VCA was incorporated into the OSIRIS-Rex Thermal Emission Spectrometer's moving-mirror assembly (OTES), facilitating accurate positioning for surface scanning as the spacecraft approached the asteroid.

To ensure high reliability and fail-safe operation, the VCA was explicitly designed with redundant technology, low outgassing, and high precision for exact motion control positioning.

To meet the size, weight, and power constraints, the VCA was manufactured in a compact housing measuring approximately two inches in diameter by three inches in length.

Sensata developed the actuator with near-zero emissions by minimizing adhesives or inks, using spaceflight-approved materials and mechanical assembly methods within a clean manufacturing process to eliminate outgassing.

High-energy Neodymium Iron Boron magnets were also incorporated to provide superior operating efficiencies.

This customized magnet solution and clean assembly methodology were applied to various actuators with varying sizes measuring 12-65 mm in diameter and 12-75 mm in length (at mid-stroke). These high-performance VCAs are ideal for semiconductor, military, space, and test and measurement applications (Figure 3).

Figure 3. High-precision voice coil actuators, such as Sensata’s model LA05-05, meet the high purity and low outgassing requirements for semiconductor, military, and space applications. Image Credit: Sensata Technologies, Inc.

Smooth Operations - Low Friction in Industrial and Processing Applications

The transportation of goods from one location to another is a widely used application. However, it can be challenging to achieve consistent motion, especially in continuously operating applications where excessive friction can impede profits and lead to work errors that decrease yields.

In such instances, it is ideal to use Voice Coil Actuator (VCA) solutions that offer precise, bi-directional position control, low hysteresis, and minimal friction, as demonstrated by the VCA depicted in Figure 4.

The VCA's symmetrical flex circuit design is critical to achieving low friction by preventing movement-induced friction, and a solid brass ball cage is used to minimize friction further.

This design results in operating performance with a hysteresis of just 10 mN, compared to similar-style actuators that deliver between 50 and 200 mN. The VCA boasts a peak force of 4.7 N, a total stroke of 7.4 mm, and a compact size of just 38 mm in diameter by 48.3 mm in length.

Figure 4. VCAs deliver low hysteresis/friction for reliable and precise motion control in a compact package. Image Credit: Sensata Technologies, Inc.

Tools to Speed Up Development

The availability of design tools to assist engineers in comprehending and implementing various technologies is crucial to their successful adoption. This is also applicable to Voice Coil Actuators (VCAs).

Sensata's Voice Coil Actuator Developer's Kit (Figure 5) is an example of a self-contained kit containing a VCA equipped with a feedback sensor and a programmable controller with PC-compatible motion control software.

These kits enable users to leverage the advantages of VCAs without having to specify the necessary electronics for a complete control system.

Using such tools, designers can rapidly create an actuation system and showcase a functional design that features velocity, position, force, reciprocation, and acceleration control to address nearly any application.

Figure 5. Self-Contained Voice Coil Actuator Developer Kits enable designers to quickly evaluate and implement a VCA-based motion solution. Image Credit: Sensata Technologies, Inc.

Moving Forward with VCA Technology

Enabling advanced precise linear motion in any location offers significant advantages for both established and emerging application areas, eliminating past obstacles related to cost or complexity.

One such application involves integrating a VCA into an electric-vehicle charging system, allowing for optimal energy transfer by lifting and aligning the coil from the floor to the one in the bottom of the vehicle. High-resolution 3D printers benefit from precise printer-head positioning achieved through VCA technology.

The range of applications benefiting from VCA technology continues to expand as engineers leverage VCAs to tackle intricate, delicate, or sensitive motion-related challenges.

Crucially, successful adoption of VCA technology necessitates identifying and developing the appropriate solution for a given application, taking into account the technology’s inherent strengths and the user’s specific requirements.

This information has been sourced, reviewed and adapted from materials provided by Sensata Technologies, Inc.

For more information on this source, please visit Sensata Technologies, Inc.