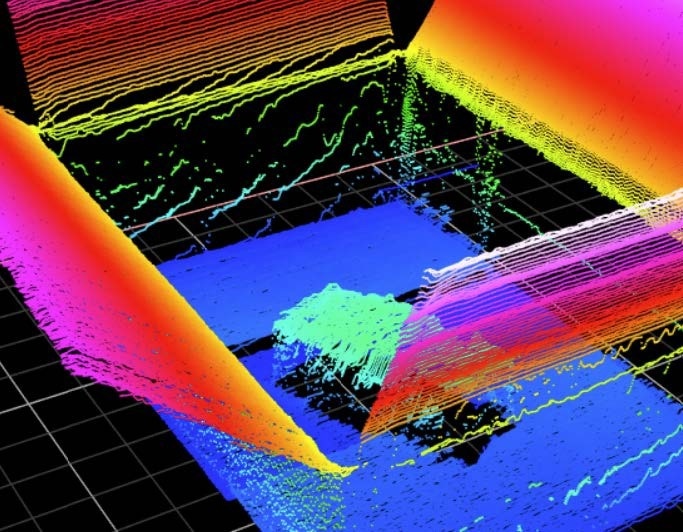

Automation is increasingly embraced by packaging and logistics providers in their efforts to minimize product packaging waste.

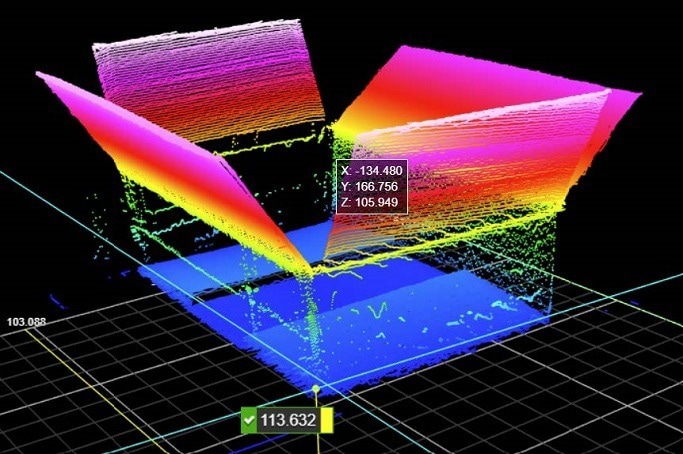

After placing a customer order inside the box, determining the remaining space within the package becomes essential for calculating the appropriate quantity of box filler material required. Excessive filler may impede proper box closure, whereas insufficient filler could damage packages.

Image Credit: LMI Technologies Inc.

Solution Summary

The Gocator 2880 sensor can be used to determine the volume of remaining space inside the box. This enables the interior examination of taller boxes effectively.

The scan output is then connected to the onboard surface processing tools of the Gocator. Detailed instructions for this process can be found in the support file below, accessible through the Emulator.

Image Credit: LMI Technologies Inc.

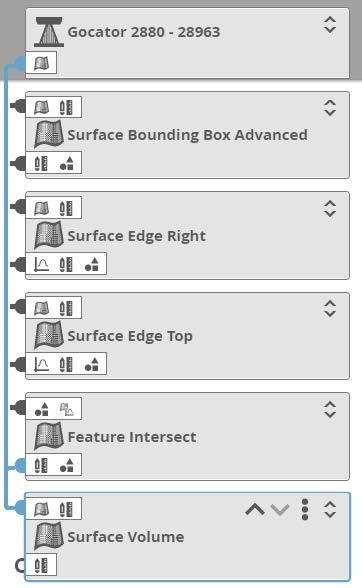

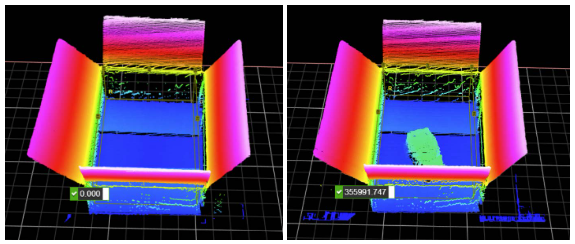

Surface Bounding Box Advanced

Given that boxes on the conveyor belt may be situated at varying positions, the Surface Bounding Box Advanced tool is employed to detect the location of each box. This information serves as a reference point for aligning other tools.

Image Credit: LMI Technologies Inc.

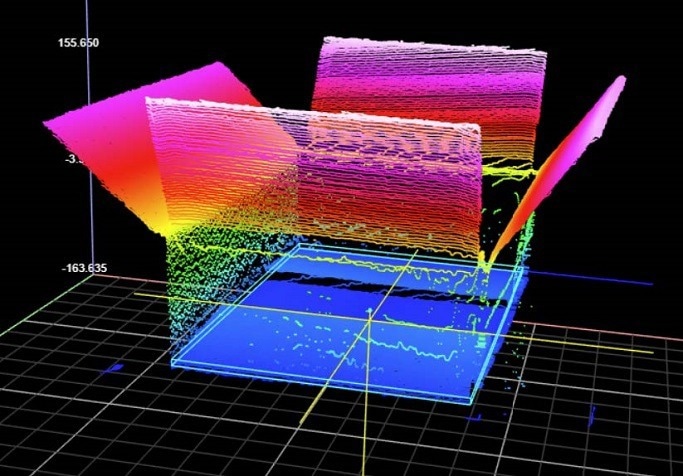

Surface Edge

For precise measurement of empty space, the Surface Edge tool is deployed to identify the right side of the box. This tool is also utilized to locate the top edge of the box, enabling the creation of two perpendicular lines intersecting at the box's corner.

Image Credit: LMI Technologies Inc.

Feature Intersect

The Feature Intersect tool processes the line coordinates obtained from Surface Edge Right and Top. It then produces an intersecting point, serving as an anchor for subsequent measurements.

Image Credit: LMI Technologies Inc.

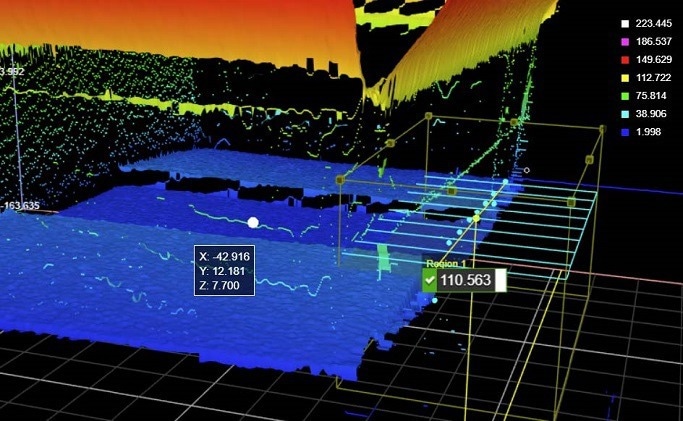

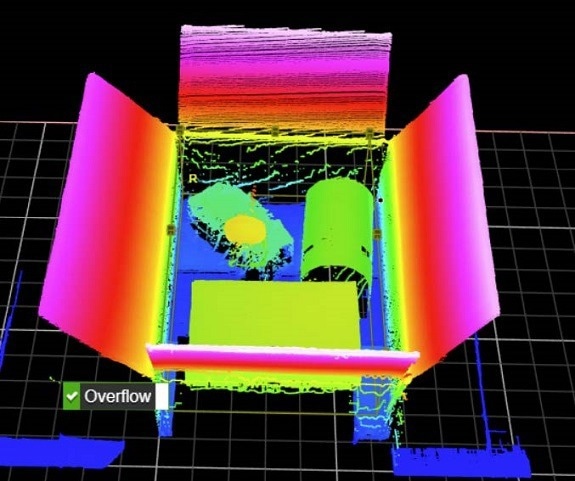

Surface Volume

A straightforward volume measurement is conducted in the concluding phase of this process. This measurement employs the Feature Intersect coordinates as an anchor point, ensuring an accurate assessment of the empty space within the box, irrespective of its position or orientation.

Image Credit: LMI Technologies Inc.

Image Credit: LMI Technologies Inc.

This information has been sourced, reviewed and adapted from materials provided by LMI Technologies Inc.

For more information on this source, please visit LMI Technologies Inc.