Yeast management, encompassing yeast propagation, addition, and control of harvested yeast, is crucial during beer production as it profoundly influences taste and quality. Implementing a defined yeast management is essential, yet the process is far from straightforward.

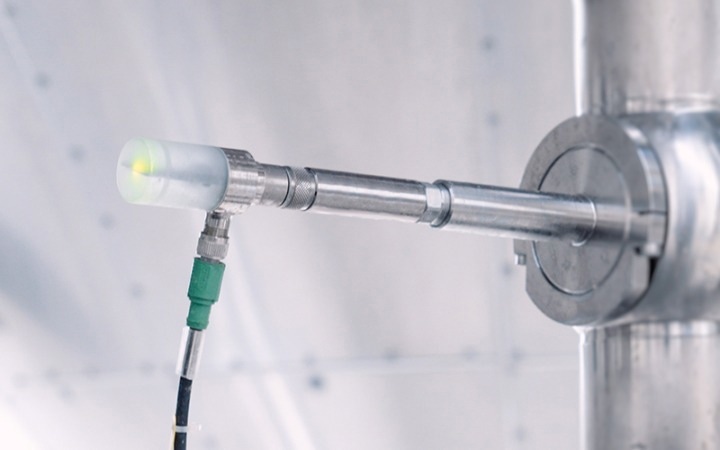

Image Credit: Hamilton Process Analytics

This article discusses the challenges and solutions to optimizing yeast management using sensor technology.

Challenges

- Counting cells manually is expensive and time-consuming.

- Foam formation during sampling makes volume determination difficult.

- The yeast tank may not be homogeneous.

- Results are not 100% reproducible due to operator variation.

The Solution

Continuous in-line monitoring of viable yeast cells, using Hamilton’s Incyte Arc viable cell density sensor, helps control the key processes in a fermentation cellar. This device will improve product consistency and reduce time and financial losses.

Image Credit: Hamilton Process Analytics

Advantages

- The quality of propagation yeast is reproducible.

- Finding the ideal time for yeast addition is easy.

- The fermentation processes are reproducible – attributable to the optimal dosage of viable cells.

- Optimum yeast harvest saves time and cost.

Image Credit: Hamilton Process Analytics

How Kulmbacher Brewery uses Hamilton's Incyte Arc Sensor

Video Credit: Hamilton Process Analytics

This information has been sourced, reviewed and adapted from materials provided by Hamilton Process Analytics.

For more information on this source, please visit Hamilton Process Analytics.