The majority of bioreactors are designed around traditional pH / ORP sensors. Due to apprehensions about connectivity with the bioreactor, operators may not consider Arc intelligent pH sensor technology. This article explores how ORP sensors and intelligent pH sensors can connect to traditional bioreactors.

Image Credit: Hamilton Process Analytics

Benchtop Bioreactors

In laboratory and R&D cell culture applications, benchtop bioreactors often have fully integrated pH electronics and associated calibration and configuration logic.

Proprietary connectors unite pH sensor cables with bioreactors. Examples of these proprietary connectors are displayed below:

Image Credit: Hamilton Process Analytics

The Hamilton Arc ECS pH/ORP Adapter is specialized to function perfectly with benchtop bioreactors. The adapter cable powers Arc sensors and switches the digital pH measurement signal back to a standard millivolt output recognized by the bioreactor.

The adapter is fully compatible with the optional Wi 1G Bluetooth Wireless Adapter, allowing mobile devices with the ArcAir software to view, configure, and calibrate the Arc pH/ORP sensor.

Hamilton offers two Arc ECS pH/ORP Adapter models:

- The Ref 243168-XX comprises a male BNC connector – which is common in specific Applikon and Eppendorf bioreactor models.

- The Ref 243169-XX has open leads to enable the addition of specialty connectors in the field or hard wiring to transmitter terminals.

Hamilton additionally offers the Arc ECS pH/ORP Adapter in custom configurations with the bioreactor connector installed at the factory.

Hamilton Arc for Traditional Bioreactors Using an ECS Adapter

Video Credit: Hamilton Process Analytics

Production Bioreactors

Larger bioreactors utilized in pilot and production frequently adopt custom Programmable Logic Controller (PLC) in their design. For pH control, the PLC needs a 4 to 20 mA analog input – which can come from a pre-existing pH transmitter or, in the context of Arc sensors, from the sensor directly.

Connecting Arc pH/ORP Sensors to the PLC

Arc pH/ORP sensors are suitable for direct connection to PLCs since they have 4 – 20 mA analog and Modbus digital outputs (no secondary transmitter is required). This saves cost and valuable panel space when designing novel bioreactors. Wiring connection options are shown below.

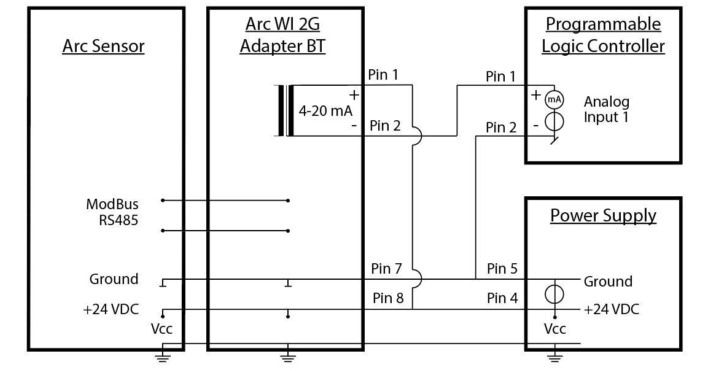

4 - 20 mA, 4-Wire with Wireless Adapter

A four-wire connection paired with a wireless adapter, like the Arc Wi 2G Wireless Adapter, is the standard wiring setup for the Arc sensor's 4 to 20mA connections to the PLC. This design offers galvanic isolation of the 4 to 20 mA outputs. It is the optimal choice for installations where wireless communication is required.

Image Credit: Hamilton Process Analytics

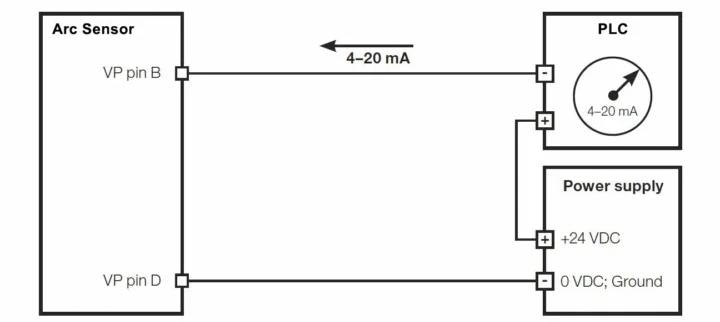

4 - 20 mA, 2-Wire Connection

A 2-wire connection scheme can also be used for Arc pH sensors. This simple connection method is less prevalent as it does not support the addition of Wi Bluetooth wireless adapters. No galvanic isolation is required in this wiring scheme.

Image Credit: Hamilton Process Analytics

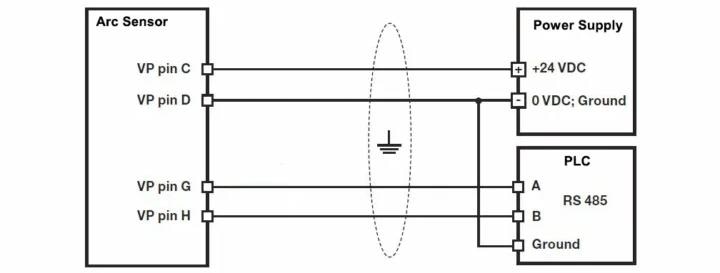

Modbus RS485 Serial Communication

All Arc pH sensors have Modbus RS485 digital communication as a standard feature. Power and signal are separated in these installations. Modbus does require additional programming at the PLC; therefore, the Hamilton programmers manual should be consulted.

Image Credit: Hamilton Process Analytics

Connecting Arc pH/ORP Sensors to Transmitters

Most pH transmitters are manufactured around sensors and, therefore, need a millivolt input signal. Although less common, Arc sensors can be connected to a pre-existing transmitter using the Arc ECS pH/ORP Adapter. The user can still benefit from offline calibration, as well as the advanced diagnostic and reporting features inherent in Arc sensor technology.

As most transmitters use terminal strip wiring, Ref 243169-XX is the optimal choice. The panel or cabinet used for the transmitter should also enclose the power supply and electronics enclosure of the adapter.

To avoid errors, temperature compensation of the pH measurement must be set to manual at 25 °C (as this compensation is performed already within the Arc electronics).

This information has been sourced, reviewed and adapted from materials provided by Hamilton Process Analytics.

For more information on this source, please visit Hamilton Process Analytics.