From mobile phones to vehicles, the modern world depends on the power of batteries. As global demand increases, improving battery efficiency is vital for environmental sustainability and product performance. Due to the huge scale of battery use today, even minuscule gains in efficiency can have a huge impact.

Image Credit: Superior Sensor Technology

This article explores the role of pressure sensors in enhancing battery efficiency. It also examines battery market trends, the optimization of battery systems, related challenges, and future outlooks. Improvements in this area rely on innovations in design, materials, and advanced controls and sensing. Pressure sensors are a vital tool that can extend the performance and lifespan of batteries by monitoring their conditions.

Market Trends

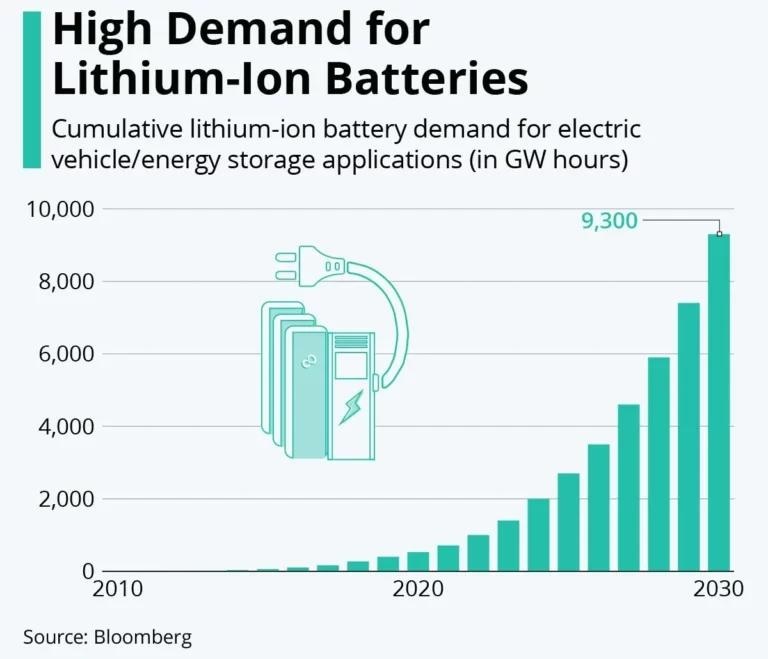

The rise of mobile devices, electric vehicles (EVs), and renewable energy storage has prompted rapid growth within the battery market in recent years.

The largest share of growth lies in the EV field. As EVs have become more mainstream, the demand for lithium-ion batteries has proliferated. McKinsey & Company speculates that between now and 2030, EV battery capacity will grow at a compound annual growth rate (CAGR) of 30%, nearing 4,500 gigawatt hours (GWh).

Mobile devices are also responsible for a large part of the market. J. P. Morgan Chase reports that consumer electronics account for 15% of lithium-ion battery demand. Battery growth in this area remains vital as more energy-intensive mobile devices enter the market.

Grid energy storage also drives market growth as more renewable energy comes online. Battery storage enables the optimization and stabilization of grids. Wood Mackenzie suggests that global energy storage capacity will grow at 31% CAGR through to 2030 and provide 741 GWh of cumulative capacity.

Pressure Sensors Explained

Pressure sensors are used in batteries to monitor their internal pressure conditions and allow the early detection of abnormal pressure buildup, which can lead to hazards such as thermal runaway.

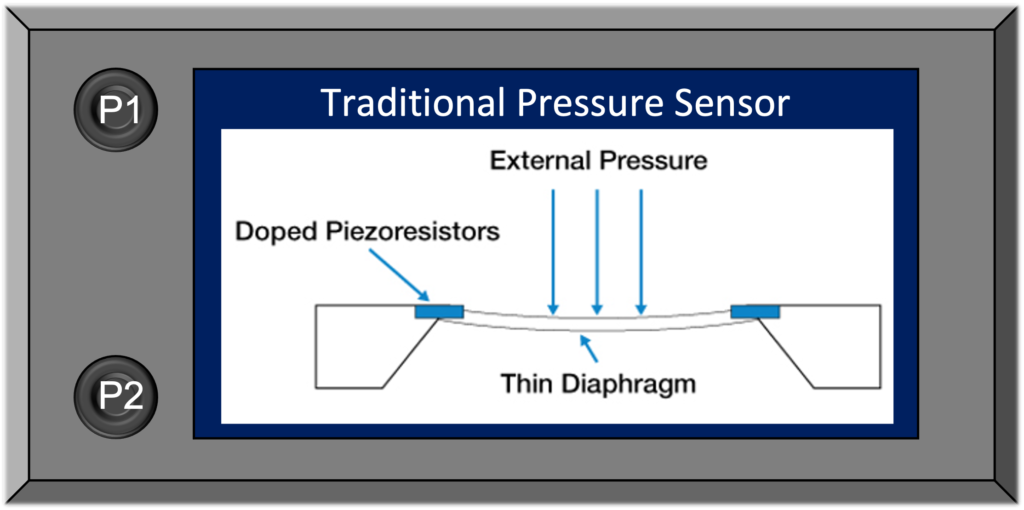

Using a piezoresistive transducer, such sensors convert pressure into electrical signals. Membranes or diaphragms in the pressure sensors deflect under applied pressure, causing a change in the resistance of the piezoresistors in the membrane. This change in resistance is then registered and converted into a pressure reading.

Figure 1. Internal workings of a pressure sensor. Image Credit: Superior Sensor Technology

Critical applications of pressure monitoring include:

- Thermal Runaway Detection: A buildup in pressure usually precedes thermal runaway. Pressure sensors can provide an early warning to prevent battery failure. Detecting a rise in pressure early allows for preventative safety measures such as cooling or disconnecting the battery.

- State of Charge (SOC) Estimation: Internal pressure changes can also indicate the SOC level as, during charge or discharge cycles, gases are generated or consumed. SOC information allows for improved adaption of charging rates and the depth of discharge to maximize lifespan and performance. Supplementing voltage data with pressure readings allows for more robust estimation algorithms for SOC and state of health.

- Mechanical Stress Monitoring: Internal swelling and material degradation can also alter the pressure. Abnormal pressure changes can be indicative of material fatigue or physical damage within battery cells prior to complete failure. Continually monitoring changes in pressure can help identify damage to batteries or aging effects.

Figure 2. Image of a swollen battery. Image Credit: Superior Sensor Technology

Incorporating pressure sensors into batteries provides significant improvements in lifespan, safety, reliability, and efficiency. Pressure monitoring is likely to become standard practice as costs decrease and sensors integrate components. Additional data dimensions can be invaluable across applications.

Pressure Sensor Challenges

While pressure sensors offer great potential for enhancing battery efficiency, integrating them into pack designs presents some challenges. The primary difficulties are cost and integration. Pressure sensors add cost to battery packs, which can impair their application. There are also expenses associated with integrating them into the pack design and collecting and evaluating the sensor data.

Integrating pressure sensors into the pack design is an additional challenge. The sensors occupy physical space within the battery cells or packs, and the packaging design must protect the sensors. The sensors also need connections and wiring for data transmission. Battery pack designs must, therefore, consider the seamless incorporation of pressure monitoring.

A third challenge lies in analyzing and utilizing pressure sensor data. The sensors produce large data sets that necessitate analytics. Companies require the knowledge and tools to transform that data into valuable insights and diagnostic information. The data also provides an opportunity for artificial intelligence and machine learning to harness sensor output to offer continuous improvement.

The Future of Pressure Sensors

The future of battery pressure sensors is bright. Market projections suggest robust growth as the benefits become more widely known. Quicker implementation will be driven by improvements in technology. Advancements in microelectromechanical systems will enable accurate, affordable, and compact sensors. Enhanced data analytics tools will offer richer insights from sensor data and enable improved monitoring and safety.

Decreases in cost are driven by ongoing innovation. As prices continue to drop, pressure sensors can be integrated more widely without a significant price increase. As innovation progresses and costs decrease, it will become harder to overlook such sensors, and they will become standard components in batteries. Their essential health monitoring and safety benefits are too substantial to overlook. Utilization will increase to meet the growing market demands for safe, high-performing, efficient batteries.

Figure 3. Surging lithium-ion battery demand through 2030. Source: Bloomberg

Conclusion

As consumer demand for EVs, grid storage, and mobile devices grows, the demand for longer battery life and improved reliability increases. Pressure sensors are an important tool for optimizing performance and preventing failures. Their distinct features unlock the full potential of current battery chemistries.

Monitoring battery pressure using sensors optimizes charging rates and prevents swelling. This is essential as batteries become bigger and more powerful. Precise pressure data enables batteries to operate closer to their limits without the risk of explosion or fire. Their widespread adoption could substantially enhance battery cycle life, capacity, and safety while decreasing expenses.

Developments in pressure sensor technology will enable safer, smarter, and more efficient batteries. As batteries are playing more important roles in various industries, enhanced pressure monitoring is critical for meeting future energy storage demands.

This information has been sourced, reviewed, and adapted from materials provided by Superior Sensor Technology

For more information on this source, please visit Superior Sensor Technology