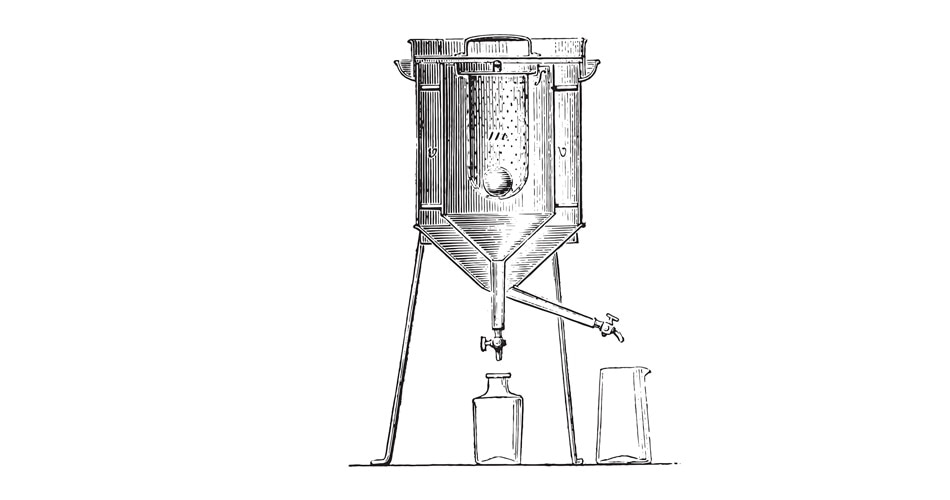

Whether you are new to calorimeters, or know a lot about them, calorimeters are tool to measure the various heat parameters in a chemical reaction or a physical change in a reaction, including the temperature change, the enthalpy and the specific heat capacity.

Reaction calorimetry is a non-invasive, non-destructive, real-time technique that yields important kinetic data, as well as providing safety data for scale-up and hazardous processes. It is a useful tool for determining whether the heat production in your reactions are viable, and for detecting any unexpected behaviour, when you’re looking to scale up your reaction process.

Reaction calorimetry provides a step-by-step analysis of the safety, scalability and criticality of your reaction process. It can also provide information that enables the user to identify issues related to the mixing, mass transfer and heat transfer processes in a reaction system.

If you are looking to take a reaction up to large scale, aside from deducing the safety data, these calorimeters can also aid in determining the correct temperature, stirring or the dosing profile.

As a general class of calorimeter, if your reaction involves heat transfer process or is largely exothermic in nature, these calorimeters will provide the user with the necessary information as to whether the process is viable from a health and safety perspective.

Interested in Calorimeters?

Interested in Calorimeters?

Heat-Flow Reaction Calorimeters

Heat flow calorimeters measure the input and output of heat energy between the reaction vessel and a surrounding thermostatically controlled jacket. The temperature of the jacket is controlled to keep it a constant temperature, allowing for an accurate temperature difference to be recorded. The jacket is to there to act as a heat source/sink with a (virtually) infinite heat capacity.

The monitoring of the heat transfer process between the jacket and the reaction vessel is performed through thermally conductive thermopiles which contain a large number of thermocouple junctions. These junctions are evenly spread out around the reaction vessel to monitor the temperature in multiple locations, so that the output readings do not suffer from localised heating errors.

The heat flow relies on the Seebeck effect. This is when an electric potential (also known as a thermoelectric force) is observed through the connection of two wires, with different metallic compositions, that are joined at both ends to the thermocouple junctions and subjected to different temperatures.

Heat flow experiments are performed through a series of steps. Firstly, the jacket and the vessel are at equilibrium to produce no heat flow. As the temperature of the reaction changes it creates a thermoelectric force which is converted into heat using the calibration constant of the calorimeter.

Heat-Balance Reaction Calorimeters

Heat balance calorimetry involves the heating/cooling of the liquid inside of the surrounding jacket to create a variable temperature that allows the reaction vessel to maintain a constant temperature (or within a required range).

These calorimeters require an accurate knowledge of the reaction systems heat capacity. Within this, the user needs to consider both the heat capacity of the reacting sample and the parts of the system in contact with the sample.

This is to ensure that the heat capacity is taken account in areas where the heat exchange takes place. This takes place once the system has reached thermal equilibrium, and at the end of the reaction.

This calorimeter is useful in reactions that involve a large volume change, as the regulated jacket temperature provides sufficient control to keep the whole system within the intended temperature range. It also provides a high resolution of the change in temperature and is often used for reactions which involve many heating and cooling cycles.

Constant Flux Calorimeters

A constant flux calorimeter utilises a heating jacket with a constant cooling/heating flux, which keeps the internal liquid at a constant temperature. These calorimeters use jackets with varying geometries and can often work at low temperatures. So, reactions which either require cold reagents, or a cold reaction temperature, can be thermally regulated with this type of calorimeter.

The contents of the reaction vessel are kept thermally constant, and when the reaction takes place alleviating heat, the jacket temperature is instantaneously increased by a step. The increase of this step is measured by the calorimeter and contains all the necessary information for the deduction of the heat capacity of the substrate(s) inside the reaction vessel.

One main advantage of this calorimeter is its ability to control the temperature under extreme environmental changes. As such, they are much simpler to use when there is going to be large changes in the temperature of the reaction vessel; and significant changes do not tend to affect the output results (or the calibrations), unlike in other calorimeters.

Power Compensation Calorimeters

In power compensation calorimeters, a constant cooling load is applied to the jacket which allows it to maintain the reaction temperature to a given fixed temperature. This method requires no calibration before or during the process so is often used to obtain rapid results.

Power compensation calorimeters offer a very direct method to quantify the process power and the enthalpy of the reaction. The reaction vessel is isothermally controlled and the jacket is normally set to a temperature below the desired reaction temperature. The calorimeter gets its name because the temperature is offset through the addition of power.

These calorimeters deduce the heat of the reaction by monitoring the amount of power supplied to a compensation heater located in the reaction vessel. The heat absorbed by the heater is determined by the difference between the initial electrical power and the required power at the time of the measurement. It is similar in its approach to heat-flow calorimeters and is often produced as a multi-use calorimeter which can utilise both heat-flow and power compensation methods.

Interested in Calorimeters? Request More Information

Interested in Calorimeters? Request More Information

Sources:

Syrris: http://syrris.com/applications/reaction-calorimetry

Mettler Toledo: http://www.mt.com/us/en/home/products/L1_AutochemProducts/Reaction-Calorimeters-RC1-HFCal.tabs.custom5.html

Molecular Energetics Group (University of Lisbon): http://molenergetics.fc.ul.pt/Heat_Flow_Cal_01.html

Principles of Thermal Analysis and Calorimetry: 2nd Edition, Chapter 8- Gaisford S., et al, RSC Publications,

Systag: https://www.systag.ch/applications/reaction-calorimeter.html

Image Credit: Shutterstock.com/MorphartCreation

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.