In this interview, AZoSensors talks to Andrew Collier of International Gas Detectors about the evolution of 2-Wire Addressable Gas Detection and the benefits it brings.

Can you give a brief overview International Gas Detectors, the kinds of products you sell and the markets you serve?

International Gas detectors has been designing, manufacturing , installing and servicing gas detection systems world wide since 1917. Originally in the mining and oil and gas industries IGD now provide solutions across a wide range of industries and applications. From simple domestic gas detectors through to complex networks covering multiple gas hazards, with a wealth of knowledge and the capability to monitor for over 350 toxic, flammable or Oxygen hazards IGD have a solution.

Typically our products will be installed anywhere where there is a threat from a gas hazard to plant or personnel. Typical applications can be laboratory complexes, gas installations, ventilation monitoring, plant rooms, power generation, schools and colleges, horticulture and many more. IGD export world wide through a network of partner companies.

Could you please explain the basic theory behind your 2-Wire gas detection technology?

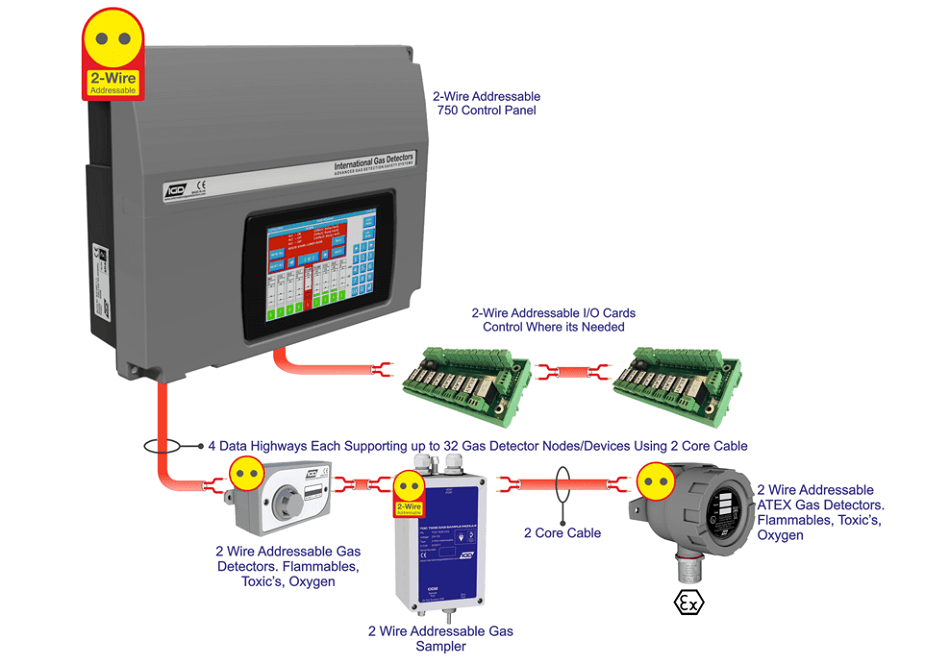

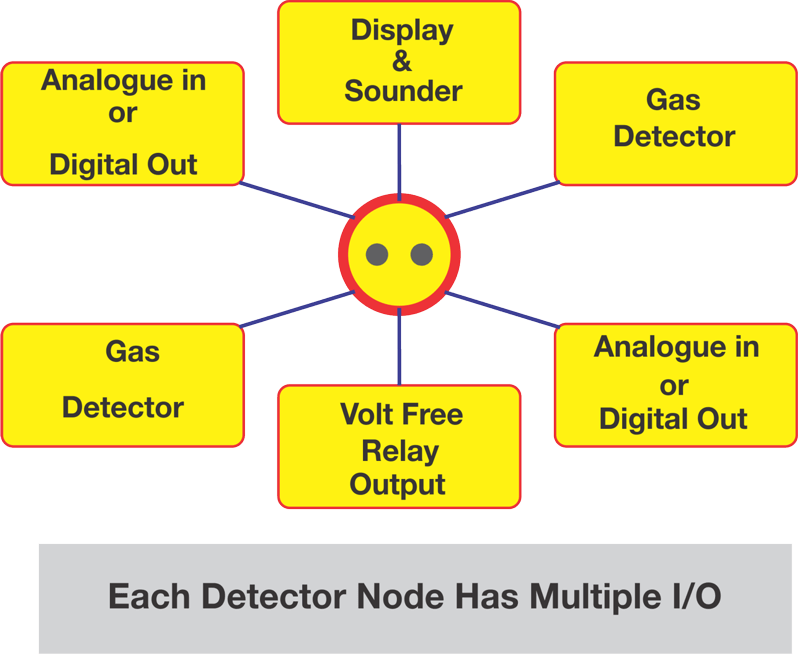

The basic idea with all our addressable gas detection, both 4-Wire and 2-Wire is to digitally network detectors. IGD pioneered the technology into the gas detection industry over 10 years ago. Our 2-Wire technology allows gas detectors to network to a controller using a 2 core cable, power and data transmission over the same wires. The detectors themselves incorporate differing detection technologies based on the gas to be detected. In addition each detector has multiple i/o options to interface to other systems. This could be as simple as a panic button interface, switching alarms or taking readings from gas meters.

How does this differ from 4-Wire or analogue gas detectors?

Gas detection systems are similar in deployment to smoke and fire systems comprising a central control panel connected to a number of detectors. Traditional UK gas detection systems have each detector directly connected by its own cable to the control panel. This results in a lot of field wiring. In addition these detectors will indicate gas levels by a changing analogue current or voltage level which is susceptible to interference. By networking detectors and communicating digitally we achieve two things;

- Reduce the install casing by as much as 70%

- Digital communication is far more reliable and allows the transfer of much more useful data

When looking at the next development of this technology IGD realised that wireless systems were not yet practical in real world situations as a safety system. If physical wiring was still necessary then the new 2-Wire systems reduce the amount of cabling to an absolute minimum. In addition the system is designed so it does not matter which way around the two cable cores are connected. So the new systems speed installation, reduce costs, reduce errors whilst providing enhanced flexibility and functionality thus future proofing installations.

What are the advantages of 2-Wire gas detectors?

From an installers perspective the systems are fast and simple to install using a normal electrical contractor. From a specifiers point of view the systems flexibility means there are no surprises. As requirements change from clients the systems flexibility can easily accommodate the change in specification. From the end users perspective these systems can generate their own reports for health and safety management for example event reporting, system health, snap shot reports etc. As sites evolve extra detection can be easily added or removed from the network. The systems can be easily integrated to site wide building management systems and or remote monitoring using GSM technology.

Where did the idea behind this innovation come from?

IGD considered the wealth of data from existing installations and consulted with our installers and partner companies. All of them wanted more for less but in subtly different ways. Installation crews want something that is fast and easy to deploy without lots of extra training. Clients want systems with sales advantages particularly in costs and features. End users need systems that enhance their safety and add value by making it easier to demonstrate compliance to health and safety requirements. IGD’s new 2-Wire systems offer something to all these groups with a win-win for all concerned.

Are there any recent examples of how a 2-Wire has replaced a 4-Wire or analogue gas detector and been a success?

Recent success stories include installations in Qatar in residential complexes with up to 320 detection points per building and multiple building monitored to a central location. The requirements continually evolved during procurement and install. 2-Wire was able to accommodate this providing an effective efficient solution.

A clean room installation in the UK benefitted from the systems flexibility as the need for the system to interface to other systems became apparent. Although not considered during the design phase, the additional interfaces included with each detector were utilised to achieve the new requirement with minimal disruption.

A recent overseas installation benefitted from the 2-Wire system due to the topography of their site. Needing to monitor for gas detection spread over a large site the client was amazed that by cascading control panels the overall system could communicate over 3KM to cover their site.

Who do you think will benefit most from the 2-Wire gas detector?

The beauty of the new 2-Wire systems is that people benefit at all levels. Wether its Easier specification, faster cheaper installs or enhanced safety and reporting everyone benefits at all levels.

2 wire gas detection systems from IGD

What’s next for International Gas Detectors?

IGD has a long history of innovation and that won’t stop. Current 2-Wire systems benefit mid to high range clients and systems. We are currently looking at introducing this technology to smaller systems with enhanced connectivity to smart devices and the IOT. More and more people are interested in the environment around them and IGD are considering ways in which we can usefully help them.

About Andrew Collier

Andrew Collier has been the Managing Director of the ‘Gas Detectors Ltd’ group of companies since 1996. Originally trained as a design engineer and working in a diverse range of companies encompassing power transmission, Instrumentation, Lens Manufacture and mass spectrometry, Andrew joined the group in 1988.

In 2007 Andrew lead the successful management buy out of the group from the existing owner, Mr Richard Oliver and has continued to develop the company, its team , products and services.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.