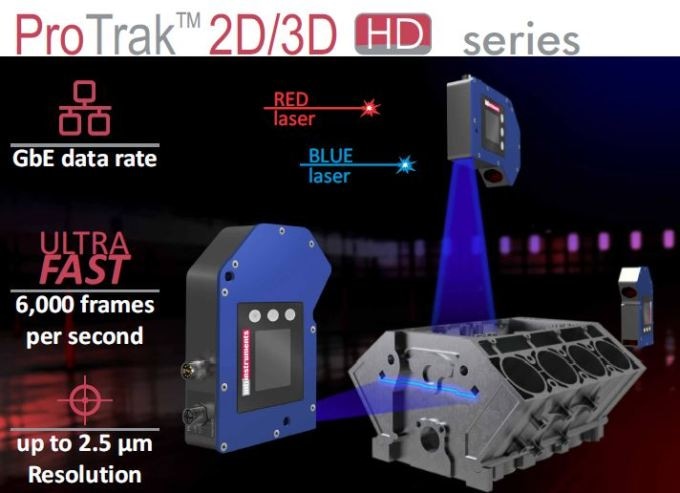

The MTI ProTrak™ laser displacement sensor is designed to meet the most challenging industrial application. The system offers an ultra-fast speed of 6,000 frames per second with up to 2.5 µm resolution and has a measuring range of up to 800 mm. It is a vital measurement tool for process automation, quality control, and tool automation control. The laser sensor is able to detect a variety of shapes and finishes and will offer users the measurement accuracy whether with individual targets or targets on a rapid conveyor belt. The calibrated line scan output signifies that users no longer need to assemble their own multiple laser/camera systems and then work out how to calibrate it. The MTI ProTrak™ laser displacement sensor offers unmatched features for different types of applications.

Features

The key features of the ProTrak™ HD laser displacement sensor are listed below:

- TCP/IP GbE

- CE compliant

- 1 gigabit per second transfer rate

- Built-in display and control panel

- 12 million measuring points

- Robot compatible, IP-67

- GbE data rate

- Red laser and blue laser

- Highly precise resolution of up to 2.5 µm

- Accurate and repeatable measurements from highly reflective to dull surfaces

- Accuracy is autonomous of environmental light and material variation

- NI LabVIEW Driver, SDK included

- Accessories available for extreme environments

- Select from different laser class (3R, 3B, or 2M)

- Models available from short range to ultra-long range

5 Measurement Ranges Available

- 60 mm

- 130 mm

- 260 mm

- 520 mm

- 800 mm

A quad B encoder input is available to sync Y dimension

- Welding

- Thickness

- Warpage

- Run-out

- Flatness

- Profiling

- Step height

- Alignment

- Fill height

- Displacement

- Angle measurement

- Dimensional gauging

- Structural dynamics

- Adhesive bead inspection

- Expansion/contraction

- Presence/absence of product

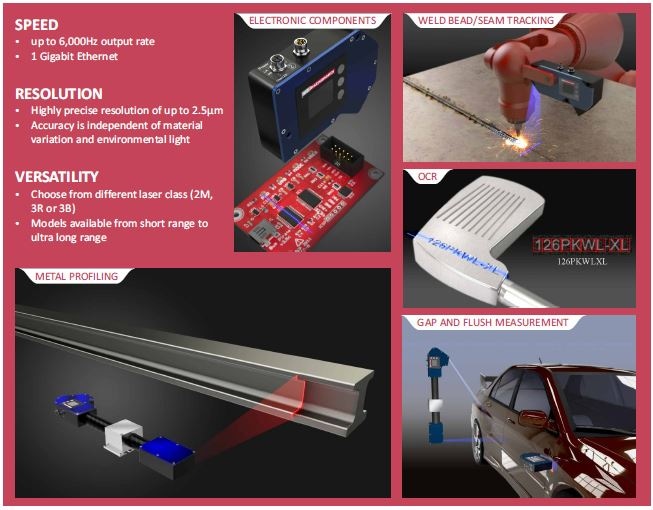

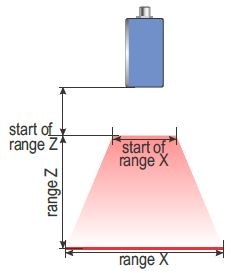

Line Scanner Measurement Principles

The ProTrak™ HD makes use of the triangulation principle to attain a 2D height profile of target surfaces. A laser line generator projects a diverging line that has a starting dimension of initial range x and maximum width dimension at end of range x. The line is then diffusely reflected back onto the CMOS camera array via focusing lenses. The CMOS line profile image is processed by the inner electronics and an X-Z calibrated array output is delivered for the application or display software at a 6 kHz update rate. When the sensor is moved along the target, the application software is able to construct a 3D image of the target. The encoder inputs permit synchronization of the motion with X-Z calibrated data.

| Model |

PT-HD 60/30/52 |

PT-HD 130/50/110 |

PT-HD 260/150/230 |

PT-HD 520/290/455 |

PT-HD 800/450/720 |

| Start of Range Z |

mm |

70 |

83 |

215 |

390 |

600 |

| Z Range |

mm |

60 |

130 |

260 |

520 |

800 |

| Resolution Z |

µm |

2 to 4.9 |

3.2 to 14 |

9.6 to 22 |

17.8 to 43 |

28 to 67 |

| Start of Range X |

mm |

30 |

50 |

150 |

290 |

450 |

| X End |

mm |

52 |

110 |

230 |

455 |

720 |

| Resolution X |

µm |

17 to 26 |

9.6 to 22 |

79 to 120 |

151 to 238 |

235 to 361 |

| Linearity Z |

µm |

9 |

13 |

26 |

52 |

80 |

| Model |

PT-HD 60/30/52 |

PT-HD 130/50/110 |

PT-HD 260/150/230 |

PT-HD 520/290/455 |

PT-HD 800/450/720 |

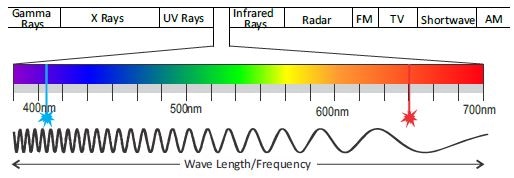

| Laser Color |

RED |

BLUE |

RED |

BLUE |

RED |

BLUE |

RED |

BLUE |

RED |

BLUE |

| Wave Length |

660 nm |

405 nm |

660 nm |

405 nm |

660 nm |

405 nm |

660 nm |

405 nm |

660 nm |

405 nm |

| Laser Class |

| 2M Product # |

8000-1034-060 |

8000-1035-060 |

8000-1034-130 |

8000-1035-130 |

8000-1034-260 |

8000-1035-260 |

8000-1034-520 |

8000-1035-520 |

8000-1034-800 |

8000-1035-800 |

| 3R Product # |

8000-1036-060 |

8000-1037-060 |

8000-1036-130 |

8000-1037-130 |

8000-1036-260 |

8000-1037-260 |

8000-1036-520 |

8000-1037-520 |

8000-1036-800 |

8000-1036-800 |

| 3B Product # |

N/A |

8000-1039-060 |

N/A |

8000-1039-130 |

N/A |

8000-1039-260 |

N/A |

8000-1039-520 |

N/A |

8000-1039-800 |

A Blue laser profile provides optimal stability and accuracy on a wide variety of targets.

The blue laser facilitates a sharper line image to be produced on the 2D sensor. The higher precision profile permits higher accuracy and less image distortion even on targets with broader ranges of reflectivities such as turned or machined metal surfaces. Furthermore, the blue laser can also outperform red laser light in particular applications such as automotive window and auto frame profiling.

Software Interface

The ProfileTrak™ HD series is provided with a free SDK software and LabVIEW drivers. Each SDK comprises of the DLL for C# and C++.

A free demo program is offered to get the 2D/ 3D sensor functioning instantly on a PC so the user can visualize if a 3D profile or a 2D profile encoder input is provided. Furthermore, the PT-HD series sensors can also function with a majority of GiGE client software such as Halcon, Matlab, and NI LabVIEW.