Columbia Series DT3716 sensors were developed to precisely monitor both strain and temperature on curved mounting surfaces. These sensors have a DIN standard 1000Ω platinum RTD that delivers precise temperature measurements at the exact site of sensor attachment, in addition to the precision, robustness and easy installation of the flight-qualified Series DTD2684 sensors.

Similar sensors have been used to monitor the expansion of the rocket body. They can also be used in several military and industrial applications that involve explosive body applications, pipe expansion measurement, aircraft surface load and all other types of engine monitoring.

Series DT3715 sensors are tailor-made to calculate circumferential strain near the diameter of the surface on which it is mounted. That particular mounting radius is custom-made into the sensor body to offer a method of controlling operator alignment method in sensor mounting.

There are models available to compensate for typical materials used in aircraft structural manufacturing, as well as for alternative materials as needed. The Columbia Model 5802 Strain Gage Amplifier may additionally power and signal condition the sensors’ strain and temperature outputs.

Note: Exports from the United States are subject to the Export Administration Regulations (EAR) and/or the International Traffic in Arms Regulations (ITAR) authorization procedures.

- Strain & Temperature Outputs

- Choice of Cylindrical Mounting Radius

- Self-Temperature Compensating

Specifications

Operational

Table 1. Source: Columbia Research Laboratories, Inc.

| Operational 1 |

Series DT3715 |

| DC Input Resistance |

1000Ω, ±2% |

| DC Output Resistance |

1000Ω, ±2% |

| Sensitivity |

1,025 (±1 %) mV/V/1000 μϵ |

| Rated Excitation Voltage |

10.0 VDC |

| Linearity |

±0.5% Max. |

| Zero Strain Offset |

±0.5 mV/V Max. |

| Operating Range |

-3500 to +5000 μϵ |

| Sensitivity Shift |

±0.005% / °F |

| Hysteresis, Repeatability |

±0.013% Max. |

| Zero Shift |

±0.00025 mV/V/°F Typ. |

| Creep |

<0.5%, 5 Min. @ 5000 μϵ |

| Temperature Sensor |

Platinum RTD, 1000Ω @ 0 °C DIN EN 60751, Class 2B (0.3 mA Max. Current) |

Environmental

Table 2. Source: Columbia Research Laboratories, Inc.

| Environmental 2 |

Series DT3715 |

| Temperature Range |

-54° to +125 °C |

| Vibration |

30 g, 10 Hz to 2 KHz |

| Humidity |

MIL-STD-202 Method 103B |

| Salt Spray |

MIL-STD-202 Method 101D (168 Hours) |

| Insulation Resistance |

100 Meg. min @ 500 VDC |

| Dielectric Strength |

1050 VRMS, 60 Hz, 1 Min. |

| Altitude |

Sea Level to 70,000 Ft. |

| Shock |

100 g, 11 mSec |

| Flammability |

MIL-STD-202 Method 111A |

| Fluids |

Resistance to short term exposure to fuel, lubricating oils and hydraulic fluids |

Physical

Table 3. Source: Columbia Research Laboratories, Inc.

| Physical |

Series DT3715 |

| Size |

0.562"Sq (Thickness Varies w/ Specified Mounting Radius) |

| Encapsulation |

Silicone Rubber per MIL-S-23586A Type I, Class 2, Grade A |

| Weight |

Approx. 15 gms (Depending on radius selected) |

| Matrix |

0.001" Polyimide |

| Leads |

#26AWG, Teflon Ins, SPC, 24" Nom. |

1 @25 °C. 2 Installed Gage

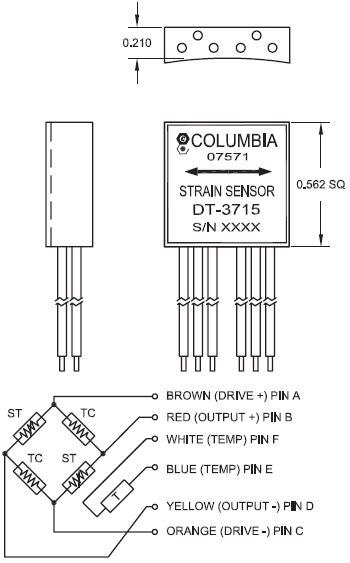

Schematic Diagram

Image Credit: Columbia Research Laboratories, Inc.

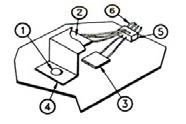

Typical Installation of Old Style Strain Gages. 1. Bolt or rivet removed from assembly; 2. Dummy gage(s) bonded to “Z Tab” of same material as structure; 3. Active gage bonded to structure under test; 4. “Z Tab” mounted to structure with bond or rivet; 5. Strain gage leads interwired and soldered to junction block and 6. Entire unit covered with protective material. Image Credit: Columbia Research Laboratories, Inc.

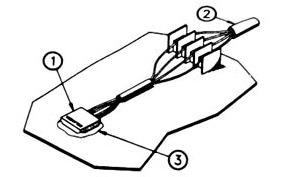

Installation of Columbia Strain Sensor. 1. Strain Sensor bonded to surface under test; 2. Leads connected to wire harness and 3. Coat sensor and wires with waterproofing material. Image Credit: Columbia Research Laboratories, Inc.

Ordering Information*

Table 4. Source: Columbia Research Laboratories, Inc.

| Model |

Lead Length |

Compensating Material |

| DT3715-1 |

24" |

Aluminum 7075-T6 or 7050-T73651, IVD |

| DT3715-2 |

24" |

Steel, AISI 4130 or HP9-4-.20 |

| DT3715-3 |

24" |

Titanium TI-6AL-4V Annealed |

| DT3715-4 |

24" |

Carbon/Epoxy MMS 549 Type 1 |

* Mounting Radius Required upon Ordering.

Advantages

- Twice as much output

- A higher level of precision

- No compromise on structural integrity

- Installation time is reduced

- Optimal temperature compensation