The Forge®️ 1GigE SWIR (Short Wave Infrared) camera series utilizes Teledyne's extensive SWIR technology expertise. The new camera series features the latest Sony® Sen-SWIR InGaAs sensors in a small form factor

The camera provides high image performance and dependability for a range of machine vision applications. It provides the perfect mix of performance, size, and GigE reliability for industrial imaging and has a broad spectral range from 400 nm to 1700 nm.

Extended Spectral Range

Capture images ranging from visible light to SWIR (400 to 1700 nm) to improve detection and analysis in various materials and applications.

Compact and Balanced Design

The compact housing strikes a balance between image performance and size. It is ideal for space-constrained settings without sacrificing image quality.

GigE Performance and Reliability

Improve GigE driver performance with the Spinnaker® SDK, Sapera™ Processing, and a robust Trigger-to-Image Reliability (T2IR) framework.

What is SWIR?

Short-wave infrared (SWIR) imaging uses wavelengths ranging from 900 to 1700 nm, just beyond visible light. Unlike visible light, SWIR can penetrate materials like silicon, plastics, and fabrics to varying degrees, revealing previously hidden details. This makes SWIR technology ideal for various industrial applications requiring precise material detection and quality inspection.

Benefits of SWIR

Enhanced Material Detection

Identify and differentiate materials based on their distinct spectral signatures and detect moisture, chemical composition, and thermal properties with high precision.

Improved Visibility in Challenging Conditions

The new camera offers better contrast and image clarity through opaque materials, in low light, and in fog. This makes it perfect for use in medical diagnostics, hot and muggy settings, and hazy outdoor settings.

Non-Destructive Testing and Quality Control

The Forge 1GigE SWIR camera permits nondestructive testing, which permits internal structure inspection without harming the object. This is essential for food sorting and industrial quality control.

Flexible Application with Narrowband Filters

Imaging at particular wavelengths improves material detection and condition monitoring. Narrowband filters are essential for a wide range of applications, including industrial inspection, scientific research, recycling, food production, and agriculture.

Application Use Cases

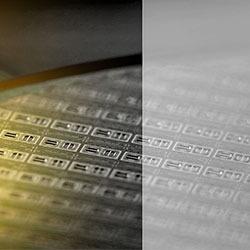

Semiconductor Inspection

Image Credit: Teledyne FLIR LLC

Extremely accurate and thorough imaging to identify defects and variations

Food Sorting

Image Credit: Teledyne FLIR LLC

Improved identification of fruit and vegetable defects, bruises, and moisture content.

Medical Imaging

Image Credit: Teledyne FLIR LLC

Excellent imaging qualities for a range of medical applications.

Material Sorting

Image Credit: Teledyne FLIR LLC

Efficient recognition and classification of various materials in manufacturing and recycling.

On-Camera Features

Factory Pixel Correction

Fix pixel flaws to produce better image quality.

Sequencer with Region of Interest (ROI)

Pin-point inspection optimizes the inspection process for specific parts of interest by allowing for the sequential, targeted inspection of individual areas.

Logic Block and Counter

This technology enables accurate and timely imaging by precisely controlling the triggering, synchronization, and output signals to peripheral devices like light sources during image capture.

Software Support

Image Credit: Teledyne FLIR LLC

- Spinnaker SDK: Comprehensive tools for image acquisition

- Sapera Processing: Superior image processing capabilities

- Integration Options: GigE Vision compliance offers a variety of connectivity options for easy integration into current systems