Nov 26 2015

The characterisation of the pressure sensors used to develop the next generation of petrol and diesel engines is crucial to optimising their design, improving efficiency and reducing emissions. The National Physical Laboratory (NPL) has developed shock tube facilities for the calibration of these sensors under the dynamic pressure conditions that they experience in use.

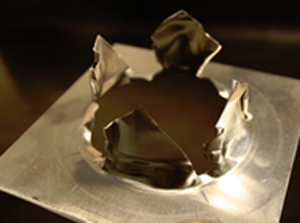

An aluminium diaphragm which is burst by gas pressure to generate a shock wave in the NPL 1.4 MPa shock tube

An aluminium diaphragm which is burst by gas pressure to generate a shock wave in the NPL 1.4 MPa shock tube

Manufacturers of petrol and diesel engines are continually seeking to improve the accuracy of the pressure measurements necessary to develop better engines. For petrol engines, intake manifold and in-cylinder pressure measurements are used to determine combustion efficiency. Diesel engine manufacturers aim to improve injector performance by direct measurement of pressures at the injectors. Sensor performance is critical under these demanding applications where the combustion of air/fuel mixtures causes flame fronts that reach temperatures of 2000 °C, and the detection of events such as engine knocking requires sensor response times that are measured in microseconds.

The accuracy of current pressure sensors is limited by not having the means to calibrate them under conditions that match those that will be encountered in use and, in particular, by only calibrating the sensors at static pressures. Parameters such as the resonance frequency of the sensors and associated fittings (e.g. mounts, connectors and pipe work), and damping and rise-times have to be estimated through computer modelling, increasing uncertainty in the sensor output under normal working conditions.

To address this problem, NPL's shock tube facilities are able to calibrate these sensors under the dynamic pressure conditions that they experience in real-world conditions. Dynamic calibration requires a source with known characteristics in both amplitude and frequency. A shock wave generated in a shock tube has a rise time of the order of 1 nanosecond, and the amplitude of the pressure step generated upon reflection of the wave from the end face of the tube can be calculated. This makes it an ideal candidate for a pressure calibration standard if it can be verified that the magnitude of the pressure step can be determined accurately from ideal gas theory using readily measured parameters such as shock wave velocity and static temperatures and pressures.

NPL has manufactured and characterised two shock tubes, of 1.4 MPa and 7 MPa capacity, investigating the effect of diaphragm material, thickness and configuration, and driven section length, on their performance.

The facility is now operational and providing traceable dynamic calibrations for pressure sensors. It has already been used by a major transducer manufacturer to investigate the dynamic characteristics of a range of their pressure sensors and associated instrumentation. In addition to the applications in the development of automotive engines, the facility has the ability to investigate the performance of gas turbines and also for the calibration of instruments used in blast studies.