Sep 15 2010

Staubli, a leading fluid connector expert, declares that they have eradicated the hazard encountered by the compressed air circuit hose, by fabricating a novel connector design that can enhance the safety as well as durability, facilitating easy handling of the pipes.

RSI coupling

RSI coupling

Unplugging the pressure filled air-lines can be dangerous if the downstream pliable hose holds pressurised air resulting in intense whipping. The maximum speed of the hose whip in the range of 145km/h can be monitored and the plug that is connected to the hose can be vulnerable and may cause injury to the person close to it.

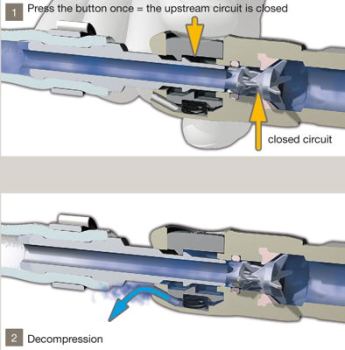

Disconnecting the latest RSI coupling from Staubli, is made easy by a press button which on pressing it stimulates a chain of processes inside the connection, enabling the unplugging process quite safely and easily. Initially, the compressed upstream air flow is shut, resulting in the decompression of the air flow downwards and in the final stage the plug disconnects automatically after reaching a low air pressure point. The air flow is completely regulated thus ensuring safety. The connectors satisfy ISO 4414 certification for the backlash protection during disconnection.

The RSI couplings permit the disconnection button installation in the most appropriate locations and the raised-button model enables performing gloves worn applications.

The leak-proof RSI connector is attainable with normal bores in the range of 5.5 mm, 8 mm or 11mm for each and operates with a pressure range up to 16 bars. The connection surface is fabricated out of a chromium and stainless steel combination which resists corrosion and furnishes hardness. The Staubli’s plug and socket connections assure a five-year warranty.