Oct 6 2016

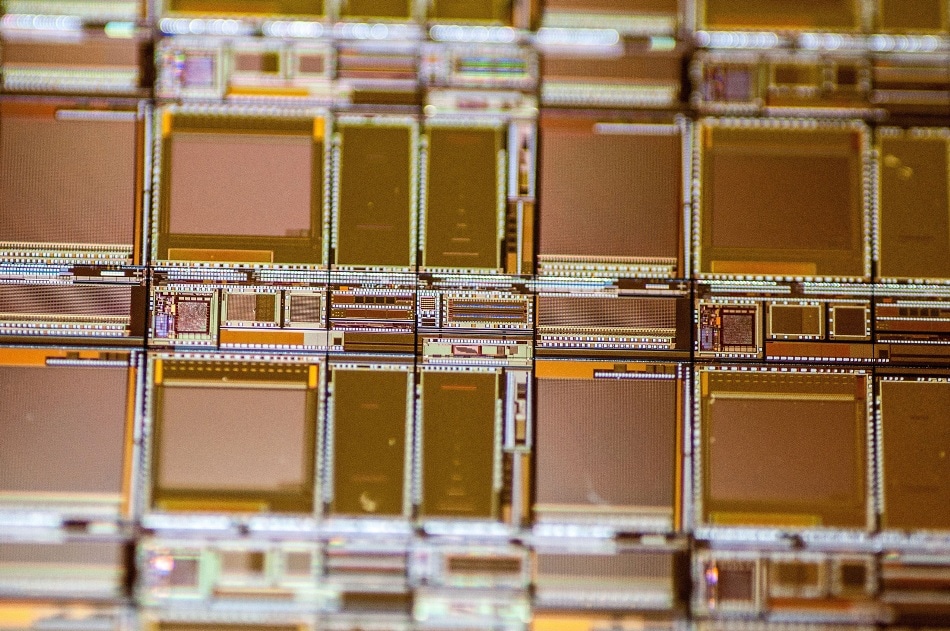

SPAD sensor chips are implemented in CMOS technology (Credit: Fraunhofer IMS)

SPAD sensor chips are implemented in CMOS technology (Credit: Fraunhofer IMS)

Developing technology that enables automated driving is the major focus of automotive industry research. Researchers at Fraunhofer have devised a new sensor system that can enhance the safety of passengers.

In the summer of 2016, news of the first major automated electric vehicle accident made the headlines. The accident occurred when the automated electric vehicle that was in the autopilot mode collided with a truck. The manufacturers of the vehicle stated that the front cameras were not able to properly perceive the oncoming semitrailer. Also, due to an inaccurate radar measurement, the emergency brakes were not activated.

A camera’s accuracy depends very much on the lighting available. In this case, it failed. The radar system recognized the obstacle, but couldn’t locate it precisely and mistook the truck for a road sign.

Werner Brockherde, Head of the CMOS Image Sensors Business, Fraunhofer Institute for Microelectronic Circuits and Systems IMS

Brockherde and team are depending on light detection and ranging technology (LiDAR), which the team has modified to suit this purpose. This technology, combined with other components, meets the needs for independent breaking, acceleration and steering. “LiDAR could have probably prevented the crash,” Brockherde states. The technology can complement the radar technology and camera presently employed in automated driving to get a full view of the driving environment, and a better perception on the traffic obstacles.

A LiDAR system emits pulsed laser beams that reflect on object surfaces. It uses time-of-light cameras to capture any signals, which are reflected back. The system can then deduce the position, relative speed and distance of surrounding cyclists, construction sites, vehicles, or pedestrians from the time taken for the light to travel to and from the obstacles. Using this data, the device can avoid collisions.

In a Flash, the Scene is Set

In order to capture the environment from 360 degrees, traditional LiDAR systems shoot one laser beam at a rotating mirror. This technology is used by Google in its driverless cars. However, a lot of car manufactures do not install these mirror-based systems, as they are heavy and prone to mechanical fault.

As a solution to this issue, Brockherde and team at Fraunhofer IMS employ ultrasensitive sensors that can obtain data on the vehicle’s complete surrounding by using only one laser flash and no mirrors. The team has named this new set of sensors “Flash LiDAR.”

These sensors use single photon avalanche diodes (SPAD), photodiodes created at Fraunhofer IMS.

Unlike standard LiDAR, which illuminates just one point, our system generates a rectangular measuring field.

Werner Brockherde, Head of the CMOS Image Sensors Business, Fraunhofer Institute for Microelectronic Circuits and Systems IMS

Compared to the photodiodes used in smartphones, SPADs possess one hundred times more sensitivity. Unlike in the original LiDAR system, both the electronic evaluation unit and sensor of the Flash LiDAR can be integrated on one chip, making it significantly sleeker and smaller. Car manufacturers can easily fit these systems behind a headlamp or the windshield. The ultimate goal of the research team is to make the Flash LiDAR capable of sensing road obstacles at a distance of up to 100 m.

“The first systems with our sensors will go into production in 2018,” Brockherde says. As these sensors operate in low light intensity, they can also be used in other application fields including analytics, medicine, and microscopy.