Sep 22 2010

Novotechnik launches an innovative angle sensor, RFA4000, which is capable of identifying the calibration angle by monitoring the direction of a magnetic field by employing a magnet, which can be integrated to a swiveling shaft in the course of operation.

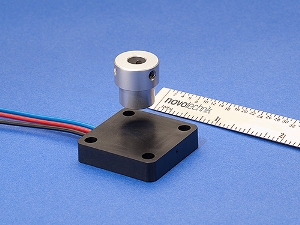

RFA4000 angle sensor

RFA4000 angle sensor

The direction of the magnetic field is altered from 0 to 360º angle format by means of an integrated IC. The processor embedded in the system inturn transforms the measured angle to a 0.25V to 4.75V or 0.5V to 4.5V radiometric readings. The working of RFA4000 is oriented on a non-touch technology basis, eliminating physical contact between the magnetic position definer and sensor thus providing wear-free operations.

The RFA400 provides a resolution with 12-bit capacity and their condensed size is in the range of 30 x 30 x 7mm3. The sensors have an extended mechanical durability and their linearity is within the range of ±0.5% with 0.1° repeatability. The SPI output series with a 14-bit resolution is also accessible. The system is shielded with quality thermal-immune plastic and sealed tosatisfythe IP67 standard criteria and thus is resistant to liquids, moisture dirt or dust.

The dual configuration of these unique sensor series and direction markers enhances the flexibility for integrating the sensors. The nominal operative shafts can be integrated with the sensors, since the sensing device employs non-contact methodology avoiding the use of bearings or shaft. Numerous non-magnetic elements can be deployed for taking the calibrations. The pc-board and leadwire coupling series are also accessible.

Various custom designed sensors can be obtained for a particular range of angular measurements along with magnetic markers for particular application purposes.