Mar 10 2017

Since Tesla is equipping all its vehicles with the same sensor suite for self-driving, the company doesn’t have the luxury to install racks of sensors hanging around its cars like other firms developing self-driving technology only on test vehicles.

Credit: Electrek

Credit: Electrek

Instead, they are putting a lot of effort into integrating the sensors, which became clear with the cameras on the second-generation Autopilot hardware suite. But they went even one step further with their latest ultrasonic sensors.

Tesla uses ultrasonic sensors as proximity sensors, for its Autopilot, and for its auto-presenting and Falcon Wing doors on the Model X.

The latter application pushed Tesla to develop new sensors, or new ways to hide the sensors, because CEO Elon Musk didn’t like the idea of a visible sensor in the middle of a door. He said when unveiling the Model X:

“We actually developed a new ultrasonic sensor that is able to do sonar through metal. In order to avoid having a puck, which is ordinally needed for ultrasonic sensors and not aesthetically good in the center of a door, we actually developed ultrasonic sensor that can literally see through metal.”

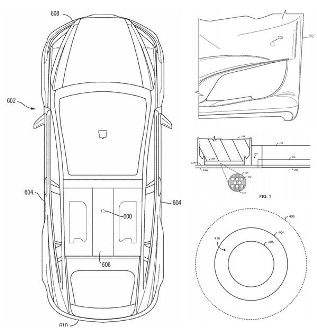

Electrek obtained the patent application for the method to integrate the ultrasonic sensor after it was released last week. The company applied for it back in August 2015, just a month before Tesla unveiled the Model X and Musk made the comment.

The application lists the method:

- generating ultrasonic waves through a panel by an ultrasonic sensor, the ultrasonic sensor having a coupling element that interfaces between the ultrasonic sensor and an inside surface of the panel, the coupling element comprising a matrix material that is reinforced with a filler;

- damping acoustic waves in the panel using a damping material placed against the inside surface and not where the coupling element interfaces between the ultrasonic sensor and the inside surface;

- absorbing airborne acoustic waves using an acoustic foam, wherein the damping material has an opening in which the coupling element interfaces between the ultrasonic sensor and the inside surface, wherein the opening is larger than the coupling element so that an area of the inside surface exists between the coupling element and the damping material, and wherein the acoustic foam is positioned so as to substantially cover the area of the inside surface; and

- receiving an echo return wave through the panel using the ultrasonic sensor.

Lots of work not to get that “puck”. The “matrix material” is made of Silicone, according to the patent.