Operations burdened with managing inventory in pie-shaped segments of silos now have a solution that provides very accurate volume data—thanks to new firmware for the 3DLevelScanner acoustic sensor.

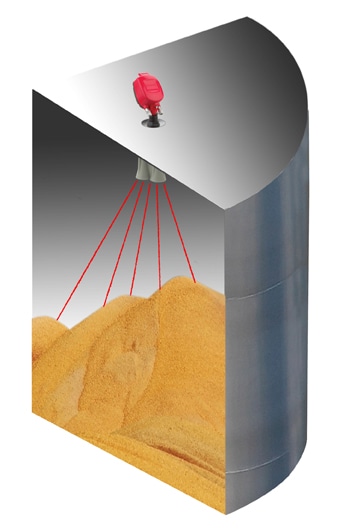

The 3DLevelScanner measures and models the topography of material contained in these unusually-shaped wedges. The newest firmware then applies the measured distances to a 3D model of vessel dimensions and converts it to a highly accurate volume measurement.

Other measurement sensors, such as non-contact radar, guided wave radar or weight and cable style sensors measure only a single distance in these formidably-shaped segments. The location of the filling or emptying points or lack of material flow may cause uneven piling of material, which could cause inventory estimates based upon a single measurement to be inaccurate. By comparison, the 3DLevelScanner maps the material surface accounting for variations then factors in the radius and height of the segment being measured, making the volume accuracy very precise.

Having accurate data about the amount and dollar value of material on hand can help reduce safety stocks, increase inventory turns, and pay for itself by freeing up cash that could be tied up in inventory. Additionally, buildup on the outer perimeter of the silo or along on the walls can be detected, accounted for in inventory, and addressed by maintenance if needed. The same 3DLevel Scanner can be used for either segmented or round silos, making it a versatile choice over its long sensor life.