Jan 11 2018

Physicists at the University of Sussex have built a new wearable technology that would enable the monitoring of sick babies in remote parts of the world. Parents at home, apprehensive about the risk of cot death, could receive automatic updates about their new babies’ heart and breathing rates via their smartphones, using ‘fitness tracker’-style technology integrated into baby sleep suits.

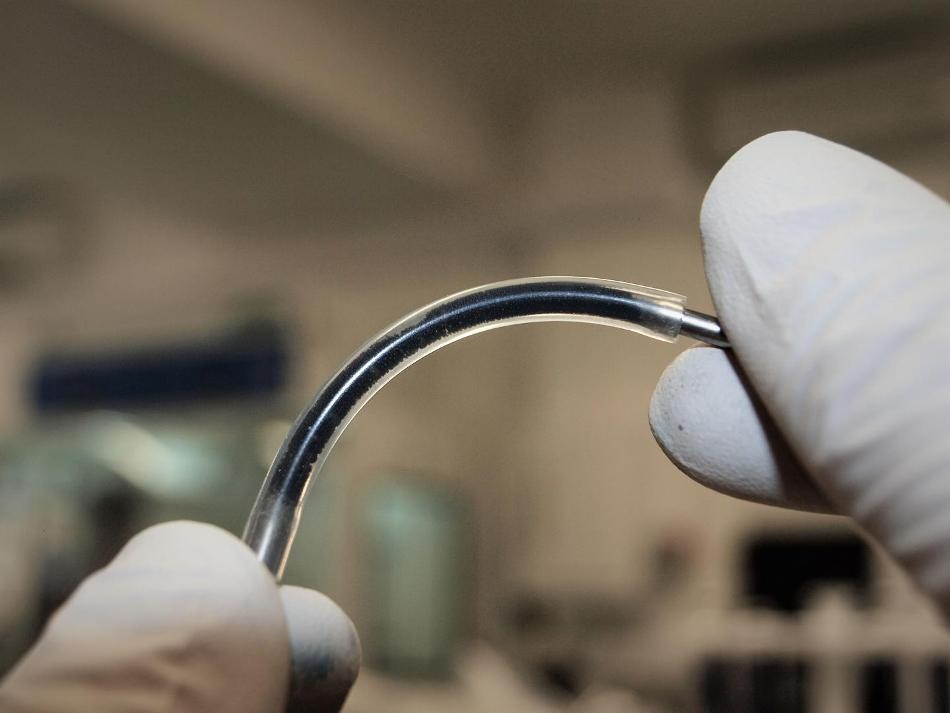

The graphene emulsion in the tube senses slight changes in pulse and respiration rates (Photo credit: University of Sussex)

The graphene emulsion in the tube senses slight changes in pulse and respiration rates (Photo credit: University of Sussex)

The modest sensors – the most sensitive liquid-based devices to have ever been built – could also be transformative for people dealing with life-threatening conditions such as sleep apnea. Furthermore, because graphene is economical to produce, the new innovation should be affordable.

Professor Alan Dalton, from the School of Mathematics and Physical Sciences, and his team of physicists at the University of Sussex have developed a liquid made from an emulsion of graphene, oil, and water, which conducts electricity. The innovation is described in a paper published in Nanoscale on 9 January 2018. A prototype has been developed and the team is in talks with commercial sponsors to fund additional research so that the product can be taken to the market.

The team was inspired to build this new health monitor after the Bill and Melinda Gates Foundation announced the need for new economical wearable health technologies for babies in situations where resources are limited.

Graphene is a 2D material composed of carbon atoms that is flexible, strong, and conductive. When a tube or channel containing the liquid is stretched, even by a small amount, the conductivity of the liquid alters. This means that the respiration rates and pulses of people wearing the device can be monitored.

Since the new liquid technology is highly sensitive, it picks up extremely small signals when attached to the body. So as to monitor the pulses of babies currently, clunky sensors have to be attached to babies’ tiny hands or feet, which repeatedly fall off. The information is then transmitted to a monitor by wires which can hamper the child’s movement.

Professor Dalton’s technological development would enable the monitoring to be accomplished wirelessly and non-invasively with a ‘fitness tracker’-like band – or even embedded within the fabric of a sensor vest that the baby can wear.

Professor Dalton says:

“Using the conducting liquid emulsions we have developed, we will produce cheap, wearable sensors based on graphene. The devices will be comfortable, non-invasive and can provide intuitive diagnostics of breathing and heart rate. We will eventually have a suit that the baby can wear which will read-out all vital information wirelessly. We hope to see this made available within two to four years.

"In the laboratory we have created a sensor that has the potential to drastically improve early detection of life-threatening symptoms such as sleep apnea or cardiac arrhythmia, where constant monitoring with conventional equipment is challenging outside of the hospital environment.

“Of course the ultimate potential is wider than that. Anyone interested in tracking their heart or respiration rates – joggers, for example – may be interested to wear this technology within their exercise gear.

"I came up with the idea for the new graphene emulsion at the core of this technology while making salad dressing – which is a type of emulsion – at home with my daughter. It’s amazing how, as scientists, we take inspiration from the everyday world around us.”

Dr Matthew Large, chief researcher on the project in the School of Mathematics and Physical Sciences, describes the latest development:

“What we’ve done is similar to how you might make a salad dressing; by shaking together water and oil, you make tiny droplets of one liquid floating in the other because the two don’t mix. Normally, the droplets would all collect together and the liquids separate over time, like the droplets in a lava lamp. We’ve resolved this by putting graphene in. The graphene, which is an atom thick, sits at the surface of the droplets and stops them from coalescing.”

Dr Large continues:

“What’s quite exciting about this new type of conductive liquid is how sensitive it is to being stretched. When the graphene particles are assembled around the liquid droplets electrons can hop from one particle to the next; this is why the whole liquid is conductive. When we stretch our sensors we squeeze and deform the droplets; this moves the graphene particles further apart and makes it much harder for the electrons to hop across the system. The sensitivity of this new kind of strain sensor is actually much higher than a lot of existing technologies, and it is the most sensitive liquid-based device ever reported, by quite a significant margin.”

Professor Dalton says:

“Graphene is very affordable as it can be produced using naturally occurring graphite, so this could be rolled out on a big scale. This is good news for health services because the new technology will not be expensive to make and buy. It also means it should be affordable to individuals.”

The paper titled, 'Functional liquid structures by emulsification of graphene and other two-dimensional nanomaterials', has been published in Nanoscale on 9 January 2018. It is authored by Matthew Large, Sean Ogilvie, Manuela Meloni, Aline Amorim Graf, and Giuseppe Fratta at the University of Sussex; Jonathan Salvage at the University of Brighton; Alice King and Alan B. Dalton, also at Sussex. The team is partnering with commercial partner Advanced Materials Development.