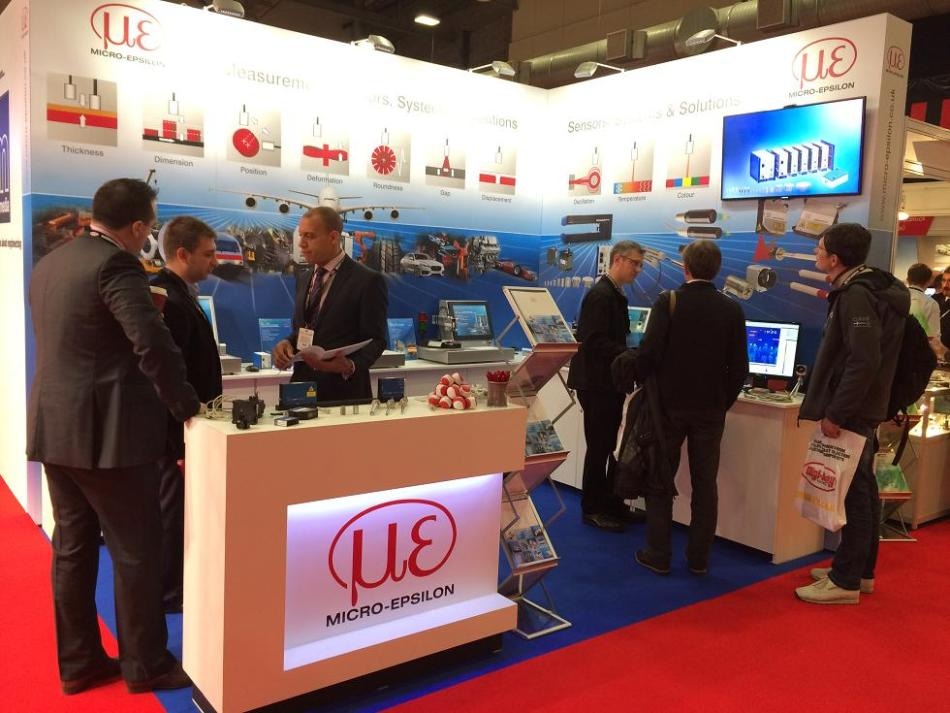

At the Advanced Engineering Show (31st October – 1st November 2018) at the NEC, Birmingham, Micro-Epsilon UK (stand F40) will showcase its full range of sensor technologies, including non-contact capacitive, eddy current and laser triangulation displacement sensors, as well as 2D/3D laser profile sensors, thermal imagers and color sensors. In addition, the stand will feature five interactive product demonstrations, including two color measurement systems:

For those with a need to measure color, the stand will feature a demonstration of the colorCONTROL ACS7000, an inline high speed color measurement system that measures the actual color of the target by identifying their coordinates in the color space. The system can be set up to continually monitor a production process and output the color measurement via Ethernet, EtherCAT or RS422. The demonstration system will show how precisely the colorCONTROL ACS7000 detects the color and intensity of a wide range of targets mounted on a turntable. Not only does the system recognize colors via a reference value (color comparison), it also ensures unique identification and measurement of all colors via the reflection spectrum. The demonstration shows how light intensity, surfaces/textures, and different materials influence the color measurement.

True color recognition

Visitors can also see a demonstration of the new colorSENSOR CFO200, a color recognition sensor designed for high precision true color measurement in industrial applications. The sensors stand out due to their high color accuracy, good reproducibility, high measuring rate and modern communications interfaces for easier network integration and Industry 4.0 capability. The CFO200 is suitable for a wide range of applications including color sorting tasks in food packaging (e.g. crown caps and labels), color inspection of interior parts in the automotive industry, recognition of color marks in the printing industry, quality control in packaging, cosmetics, medicine and plastic products.

Measuring gaps and edges

Also on the stand is a demonstration of the gapCONTROL non-contact laser profile scanner. This sensor is designed specifically for the measurement of gaps and edges. Users can quickly and easily set up and configure the scanner without requiring any specific knowledge or programming skills. Typical applications include measuring flushness, proximity, gap width and depth, height differences, center position, angle, collision avoidance and overlapping edges. The latest additions to the gapCONTROL series, the 2611 and 2911, are even more compact and provide additional functionality including the ability to measure even smaller gaps.

Injection molding temperature control

The moldCONTROL inline thermography system detects variations in quality by using a high speed, high resolution infrared thermal imaging camera. It records the entire component in up to six different views and examines it. The principle is simple: a thermoIMAGER TIM thermal imaging camera records the infrared radiation emanating from the mold and visualizes it. The temperature distribution provides a quality statement about incorrect temperature control of the mold, malfunction of the tool temperature, visible geometry errors and hidden defects. On the stand, the demonstration involves the temperature measurement of plastic injection molded LEGO bricks.

Laser triangulation at its best

Visitors can see a demonstration of the optoNCDT 1420 laser displacement sensor. The speed, size, performance and ease of integration of these sensors is unrivalled in the market today. The sensors are suitable for a variety of medium-to-high volume applications in automation, machine building and systems integration, particularly where conventional laser sensors have reached the limits of their performance capabilities. The sensors are extremely compact, lightweight and so can be mounted in tight spaces on machines or other difficult-to-access locations. Designed for high precision, high speed, dynamic displacement, distance and position measurement applications, the sensors offer an adjustable measuring rate up to 4kHz and an excellent price-performance ratio, particularly for high volume OEM applications.