How the P53 Ultrasonic Sensor improves professional cheese making by providing hygienic measurement of curd levels.

This new case study from Hoffmann + Krippner, Inc illustrates how the P53 Ultrasonic Sensor by PIL can improve hygienic conditions and equipment for safe and high-quality cheese making processes.

Any equipment used in food production must meet the highest standards of hygienic design; food safety and quality depend on it.

As shown in this case study, the hygienic ultrasonic sensor series P53 by PIL are used for level detection in a coagulator system designed by ALPMA (Alpenland Maschinenbau GmbH).

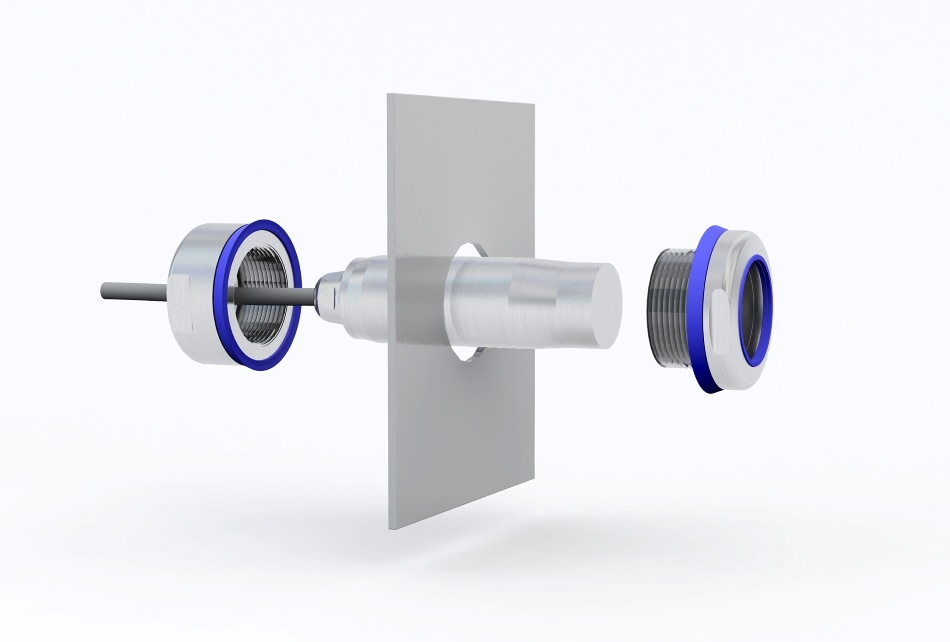

Fully encapsulated in edgeless a stainless-steel housing (rated up to IP68/IP69K) with a EHEDG-certified holder, the P53 ultrasonic sensor provides a highly accurate and reliable sensing solution that can withstand thorough cleaning with highly acidic and/or alkaline cleaners as well as high-pressure or jet-steam cleaners.

To learn how the P53 ultrasonic sensor is the perfect solution for safe and hygienic food production processes, please download the full case study here: https://www.hoffmann-krippner.com/pdfs/HK_CaseStudy_P53.pdf.

Learn more about the coagulator by ALPMA with the P53 ultrasonic sensor at https://www.youtube.com/watch?v=eFWpf1Lv2Xw.

Learn more about the complete production line for soft cheese with WALDNER and ALPMA equipment at https://www.youtube.com/watch?v=oqhVERmwLpQ.