By Megan DaviesMar 20 2019

By Megan DaviesMar 20 2019Sensors facilitate the automation of production and logistic processes and are accordingly the basis for effective added value. Precise sensor technology forms the foundation for industry 4.0. So far, radar-based sensors play a peripheral role in industry. Yet, their rewards are obvious: Compared to optical sensors, radar systems are not influenced by challenging visual conditions and, opposed to X-rays, they pose no risk to health. The Fraunhofer Institute for Applied Solid State Physics IAF creates compact and high-resolution radar systems, which can considerably boost the efficiency of various industrial processes. The latest technologies will be showcased at Hannover Fair 2019 (Hall 2, Booth C22), between April 1st and 5th.

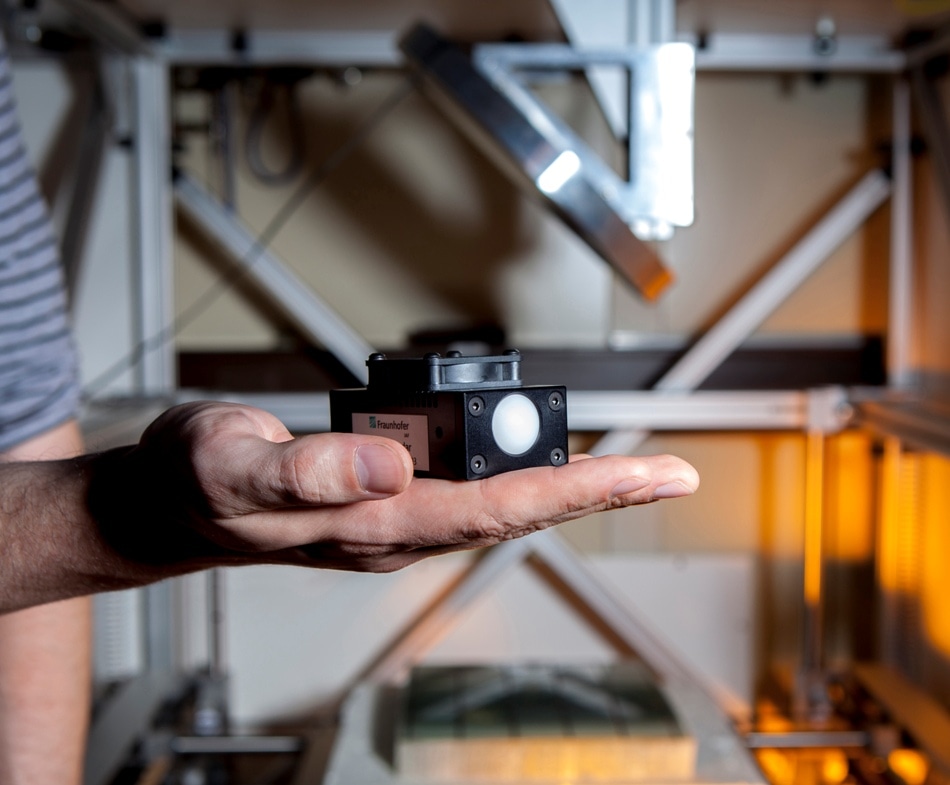

The compact W-band radar is able to precisely measure positions, spacings, distances, and velocities, even if the objects are barely visible or concealed. (© Fraunhofer IAF)

The compact W-band radar is able to precisely measure positions, spacings, distances, and velocities, even if the objects are barely visible or concealed. (© Fraunhofer IAF)

The radar systems created at Fraunhofer IAF function in the millimeter-wave range and are able to pierce through most non-metallic materials such as wood, cardboard, plastic, textiles or even smoke, dust, and fog. They can precisely measure spacings, distances, and speeds, even if the objects are hardly visible or hidden. The experts of Fraunhofer IAF make use of these properties of millimeter-waves to create high-resolution radar modules for industrial sensor systems. At the 2019 Hannover Fair, Fraunhofer IAF presents its compact W-band radar (75-110 GHz) which can examine packaged goods for content and wholeness remotely and in real-time. In this manner, it can sort out defective deliveries of goods prior to shipping and thus curtail return flows.

Extremely precise even under challenging visual conditions

Until now, commonly optical sensors, like lasers, are being employed for presence detection during manufacturing processes. The challenge, in this case, is that lasers do not function in environments where there is less visibility and cannot measure through optical barriers. The W-band radar, however, provides very precise distance measurement regardless of the visibility condition and with a sub-millimeter precision. Besides presence detection, radar technology formed at Fraunhofer IAF offers a broad range of applications: “Our radar sensors can be used wherever contact-free material inspection or highly precise distance measurement under difficult conditions such as heat or restricted vision is needed”, explains Christian Zech, scientist at Fraunhofer IAF. At present, Freiburg’s Fraunhofer Institute is working on several projects to adapt its radar technology for particular industrial requirements.

Safer human-robot collaboration

Zech’s project team adapts the radar for human-robot partnership, which will help to enhance the wellbeing of people. Humans and robots will be expected to gradually interact directly with each other in tight spaces of production settings in the future. Safety systems are essential to guarantee the safety of people continuously. Simultaneously, a comparatively uninterrupted movement of the robot must be made possible for full efficiency. Therefore, the researchers work on a new solution for the safety of people founded on compact high-resolution radar systems that survey the collaboration space, measure dynamic safety zones, and alter the speed and movement of the robots according to the situation. With these resources, a robot can adjust its own movement according to human actions without disturbing its task, and hence, ensures a safe and efficient partnership. “Such a radar safety system can utilize the maximum possible movement speed at minimal distance. This leads to a faster, and thus more efficient, collaboration between humans and robots”, sums up Christian Zech, project manager of “RoKoRa”.

Saving energy in the iron and steel industry

The steel sector is one of the largest energy-intensive sectors. Thermoprocessing plants and industrial furnaces guzzle nearly 40 % of the total industrial energy demand. So as to remain globally competitive, the steel sector needs to boost the efficiency of current production plants and markedly bring down energy consumption. To achieve this, a multi-disciplinary consortium including Fraunhofer IAF develops a radar-based measuring technology for hot rolling mills: This radar sensor technology not only facilitates a strong high-resolution detection of positions and distances of flat steel, but also for exact and contact-free measurements of speeds and lengths. “Rough conditions dominate hot rolling mills – extremely high temperatures, dust, high humidity, and steam complicate the use of optical measuring systems. High-resolution radar sensors control precise band and process sizes and thus ensure a reduction of defective goods, which corresponds to increased profit. This saves resources and energy”, explains Benjamin Baumann, project manager of “Rad-Energy” on the part of Fraunhofer IAF.

Longer-lasting wind turbines

Millimeter-wave radar technology can not only establish dimensions of materials, but can also penetrate them, for instance, to locate flaws and their precise positions within materials. The researchers of project “InFaRo” have developed an innovative testing technique for wind turbine rotor blades that can spot imperfections as early as during manufacture. This boosts their quality considerably and also saves operating and production costs.

The production, assembly, and working of wind turbines are being advanced in each generation. The rotor blades created from fibrous composite materials in sandwich design, built as hollow parts, are required to endure extreme forces while in operation. The size expansion of rotor blades from 40 m (2006) to over 80 m (2014) results in ever growing demands on their manufacturing. Fractures and cracks in blades result in huge material damage and inefficient power plants and even pose a risk to life.

We develop an innovative measuring system based on radar and thermography, to detect even smallest material defects such as delamination, folding or air inclusions during production. This ensures an increase in safety and efficiency of wind turbines, while at the same time lowering their cost.

Dominik Meier, Project Manager and Scientist, Fraunhofer IAF.

Direct material inspection has a number of advantages: The quality of the rotor blades increases considerably, wind turbines become more hard-wearing and downtimes because of flaws can be brought down to a minimum.