Mar 21 2019

A unique sensor system designed in Saarbrücken, Germany is capable of not only carefully regulating drying processes in industrial ovens, but also delivering consistent air humidity measurements even at high temperatures and when other background vapors are present. Professor Andreas Schütze, project manager Tilman Sauerwald and their research team at Saarland University have created with partner companies a sensor system that efficiently checks industrial drying, baking, and cooking processes. The new system enhances product quality, enhances the production process and minimizes process energy demands. The project has been funded by the Federal Ministry of Education and Research’s priority funding program “KMU-Innovativ” that supports groundbreaking technology in small and medium-sized enterprises.

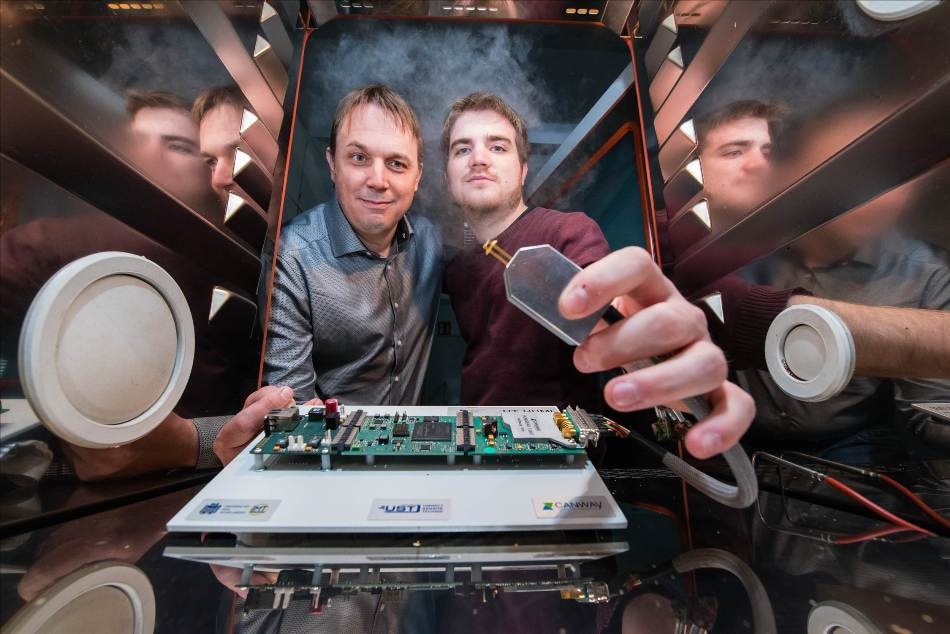

A sensor system that precisely measures air humidity even in hot industrial ovens: Project manager Tilman Sauerwald (left) and PhD student Henrik Lensch from the research team led by Professor Andreas Schütze. (Photo credit: Oliver Dietze)

A sensor system that precisely measures air humidity even in hot industrial ovens: Project manager Tilman Sauerwald (left) and PhD student Henrik Lensch from the research team led by Professor Andreas Schütze. (Photo credit: Oliver Dietze)

The engineers will be demonstrating their heat-resistant sensor system at the 2019 Hannover Messe (Hall 2, Stand B46) between 1st and 5th April.

When food is being steamed or baked as part of an industrial production process, it is crucial to keep a close watch on the humidity levels. If baked goods or bread lose a lot of moisture or lose it too rapidly, the end products will not have the desired properties. If, on the other hand, the humidity in the oven can be precisely controlled, the croissants will bake perfectly fluffy and the bread will have an appetizingly crisp crust. “Precision monitoring of humidity can have a crucial effect on the quality of the products. Knowing the humidity levels allows us to carefully control the temperature and air volumes during the production process, and thus also save on energy,” says Professor Andreas Schütze of Saarland University—an expert in the field of sensor and measuring technology. Exact measurements of moisture content are also important when drying textiles, wood, and coatings in industrial dryers—mainly to prevent heat damage to the materials.

When taking humidity measurements, it is vital that temperature variations are noted precisely, as improper temperature readings can render erroneous the humidity data. Another issue that has to be looked into is the fact that other gases are also discharged at the high drying temperatures used in industrial dryers and ovens. For instance, alcohol is released during the baking process and several volatile compounds are discharged when coatings or paints are cured or dried. Thus far, conventional humidity sensors have found it hard to monitor relative water vapor levels because of the presence of these other elements in the hot air. And these aerial compounds can considerably cut the lifetime of the sensors or even impair them. “In such cases, we talk about the sensor becoming poisoned,” explains Tilman Sauerwald, senior scientist in Schütze’s team. When all these aspects are taken together, it clarifies why the humidity measuring systems available till now have had limited service lives and have not been particularly precise or have been very costly.

Measurement technology researchers at Saarland University have built a sensor system that can establish the humidity in industrial dryers and ovens with extremely high accuracy even at very high temperatures and in the presence of background disturbances from other gases. The measurement technology used is intricate, but it does a lot more than just recording data on specific quantities.

We use a special ceramic sensor in combination with a Fourier transform impedance spectrometer. This allows us to make measurements across a large dynamic range and gives us excellent resolution over a wide range of temperatures.

Henrik Lensch, a PhD student, Professor Schütze’s Team, Saarland University.

The scientists measure the electrical impedance (i.e. the frequency-dependent resistance to current flow) at various frequencies and compute from this the equal resistance and corresponding capacitance values as well as a wide spectrum of other quantities. “The resulting spectral data then undergoes model-based analysis,” explains Tilman Sauerwald. The analyzer unit uses mathematical models to extract those factors that are applicable to the humidity measurements. The analyzer can identify and filter out those interference signals that have no connection with the humidity. Using this method, the sensor system can also detect when a fault condition or fault occurs.

The research project is a partnership between Professor Schütze’s team and the companies Canway Technology and UST Umweltsensortechnik.

The scientists will be seeking partners with whom they can develop their technology for novel applications.