Apr 8 2019

Although a finger print can act as identification to access a number of things, including locked doors, present-day scanners can be tricked with fake fingerprints or even analogous ones. However, that may soon change, thanks to a Japan-based collaborative research team.

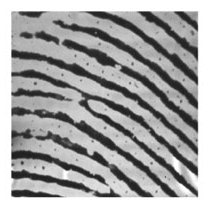

Proximity capacitance image of a fingerprint. The captured image clearly shows not only the fingerprint, but also sweat pores of the skin. (Image credit: Shigetoshi Sugawa, Tohoku University)

Proximity capacitance image of a fingerprint. The captured image clearly shows not only the fingerprint, but also sweat pores of the skin. (Image credit: Shigetoshi Sugawa, Tohoku University)

The researchers have created an innovative proximity capacitance imaging sensor, whose resolution and sensitivity are so high that a finger print scan can detect the sweat pores existing between the ridges, in addition to showing the swirls of a fingertip.

This novel prototype sensor was initially presented at the 2018 IEEE International Electron Devices Meeting in San Francisco, California, in December 2018. The Technical Digests of 2018 International Electron Devices Meeting featured an article elucidating the details of the novel sensor. Then, at a conference organized by the Institute of Image Information and Television Engineers (ITE) in Japan, the authors presented the study results and the new materials on March 22nd, 2019.

The most significant point of the developed sensor is its high capacitance sensitivity.

Shigetoshi Sugawa, Study Author and Professor, Graduate School of Engineering, Tohoku University

A majority of computer track pads and touch screen phones utilize a less sensitive capacitance sensor, in which the variations in electrical properties between a conductive tool (for example, a finger) and a sensor enable the device to respond to double clicking or scrolling. When the object is closer, the capacitance increases—double-clicking against lighter scrolling.

According to Sugawa, the capacitance sensor’s high sensitivity is obtained from the newly launched noise reduction technology. Pixels integrated in the sensor chip detect the capacitance between the detection electrodes and the sample. Every pixel includes a single detection electrode connected to it that is capacitively linked to a ground wire. Such electrical signals are changed into images of the samples. Earlier, the signals will detect background noise like thermal noise and noise owing to variability of pixels’ electrical components, which resulted in lower-quality images.

In order to overcome this problem, the team introduced reset switches to the detection electrodes and then used a voltage pulse to create a circuit that can track the source of noise. Through the reset switches, the systems are able to pick up the noise emerging at the detection electrodes. Once the reset switches are switched off, the voltage pulse alternates the two voltage levels thus efficiently cancelling out and eliminating noise from the system.

It is just like removing the black and white snow from a television without any signal inputs into a smooth and grey screen. Any deviation on a solid background can be sensed more easily.

This development is important to the general public because it can improve the efficiSency of analysis and control in the fields of electronic industry, authentication, life sciences, agriculture, and more.

Shigetoshi Sugawa, Study Author and Professor, Graduate School of Engineering, Tohoku University

Sugawa and the research team are now planning to improve the sensor for particular applications, like the non-contact inspection equipment of flat panels and printed circuit boards, and also a portable camera system integrated with the developed sensor chip.

The research team includes Sugawa, and also Rihito Kuroda, an associate professor, Manabu Suzuki and Masahiro Yamamoto, both graduate students with the Graduate School of Engineering of Tohoku University; Tetsuya Goto, an associate professor with the New Industry Creation Hatchery Center of Tohoku University; Hiroshi Hamori, president, Shinichi Murakami, and Toshiro Yasuda, at OHT, Inc.