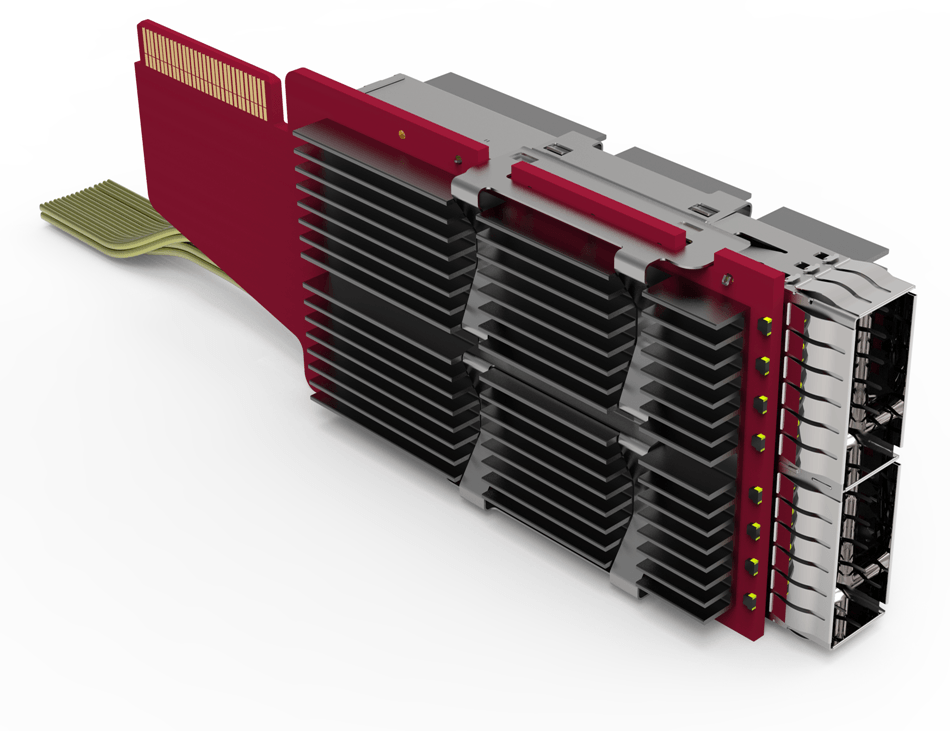

Molex, a global electronic solutions provider, highlights its new BiPass thermal management configuration cooling QSFP-DD modules up to 20W with a 15 degree Celsius change from the ambient temperature. First shown at DesignCon 2019, the Molex QSFP-DD thermal solution can cool a range of 15W to 20W in different configurations. The BiPass solution allows higher wattage modules to be cooled and will help designers on the path toward 112 Gbps.

As the industry is readying for the launch of next-generation copper and optical QSFP-DD transceivers, thermal management strategies are critical. During the demonstration, Molex showcased a QSFP-DD belly-to-belly BiPass configuration, QSFP-DD belly-to-belly SMT configuration, 2x1 QSFP-DD stacked configuration and 1x2 QFSP-DD BiPass in a vertical orientation with dual heat sinks. Running at 15 W, all configurations were able to cool at less than 25 degree Celsius delta T rise. The BiPass solution routes high-speed signals through Temp-Flex twinax cables enabling greater channel margin compared to PCB alone and allows for a second heat sink on the bottom side of the cage to make contact with the module, providing additional cooling.

“If you need to be able to cool a 15W module, there are a number of different solutions available today,” said Chris Kapuscinski, global product manager, Molex. “We now have the ability to cool higher wattage modules. The BiPass solution has the opportunity to save designers money as well as be a key enabler as we move forward with 112 Gbps PAM-4 implementations.”

The BiPass solution, allows designers to bypass the lossy printed circuit board by utilizing Temp-Flex high-speed twinax. Because of this, they can achieve lower insertion loss when going from an ASIC in a switch or a router to another server within a rack. Advances in heat sink technologies are enabling highly efficient, reliable and resilient thermal management strategies to support higher density in both copper and optical connectivity. From a future perspective, this great signal integrity performance and low insertion loss capability allows designers to use passive copper throughout the entire design.

“As demand for faster data rates grow, data center technology is evolving quickly, and thermal management technology must keep up. The BiPass solution allows for better temperature control of a system using advanced materials, the latest tools and cutting-edge technologies without compromising performance,” adds Kapuscinski.