Expanding upon MSA’s highly intelligent TruCal® sensor platform, the launch of its new industry-first Diffusion Supervision technology listens for and alerts plant technicians to blocked electrochemical sensor conditions.

MSA’s unique Diffusion Supervision technology automatically warns users when an electrochemical sensor inlet becomes blocked and unable to detect gas. This early warning feature gives industrial plant users peace of mind in knowing that toxic gas leaks can be detected between scheduled calibrations/visual inspections.

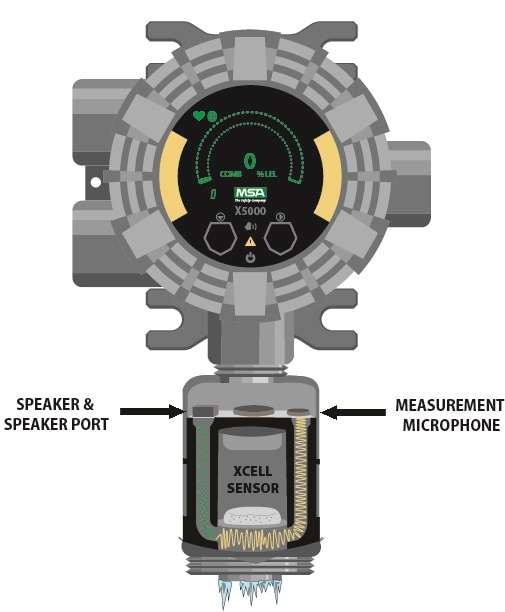

TruCal technology is enabled through MSA’s patented XCell® sensors and consists of Diffusion Supervision (DS) and Adaptive Environmental Compensation (AEC). Diffusion Supervision employs proprietary acoustic mechanical design and algorithms to measure sound across the sensor’s inlet every six hours. If the inlet is blocked with a material, such as ice, the difference in the sound is detected and the unit goes into fault after a 24-hour period. When the obstruction is removed, Diffusion Supervision detects the clearance and returns to normal operation.

Adaptive Environmental Compensation (AEC) corrects sensor drift and extends calibration periods using a pulse check four times a day. The pulse check uses TruCal’s patented technology to calculate gas response by applying an electronic pulse to the sensor and analyzing the response curve. Through proprietary algorithms, TruCal can quantify gains and losses in output sensitivity that result in accuracy adjustments during the pulse check without the use of calibration gas.

TruCal technology with DS and AEC capabilities checks that a sensor is free from obstruction and operating within its predetermined sensitivity limits and is corrected to account for drift or change since the last calibration or pulse check event. If the output signal has drifted outside of the acceptable range, the instrument notifies the user that gas calibration is necessary. With DS functionality, users will know within 24 hours if a gas sensor becomes blocked and unable to detect gas.

MSA’s industry leading TruCal technology features six advantages over legacy gas detectors to better protect people, equipment and facilities in hazardous industries. It validates that the sensor is operating normally and that the inlet isn’t blocked, as well as compensating for sensitivity drift due to changing environmental conditions. It also recommends when a full calibration should be performed and warns when a sensor needs to be replaced in the near future reporting the life and health status as “Good” or “Fair”, alerting technicians that the device is no longer able to monitor the area.

TruCal technology is found exclusively on XCell Hydrogen Sulfide (H2S) and Carbon Monoxide (CO) gas sensors for the Ultima X5000 and General Monitors S5000 gas monitors from MSA. This platform has integrated cutting-edge technology such as non-intrusive touch button operation, dual sensor capability, extended calibration cycles and Bluetooth® wireless communication offering benefits such as a low total cost of ownership and a completely new user experience making it years ahead of its time.

Process, plant and safety engineers can rest assured of accurate gas sensor functionality. TruCal technology automates much of the hard work previously performed by technicians. It provides continuous calibration to avoid missed or false alarms that can result in accidents or reduced productivity while at the same time freeing plant technicians to attend to other tasks throughout the plant, to reduce labor costs.