With the VeriCal In-Situ Calibration Verification System for the ST00 Series Flare Gas Flow Meter from Fluid Components International (FCI), process and plant engineers can now eliminate the cumbersome task of traditional flow meter calibrations, which require shutting down the line, pulling the meter, installing a spare and sending the meter out to a lab to help meet air quality management regulations.

The ST100 Flow Meter is now available with either an optional integral VeriCal System or a Kit System, which can be used for retrofitting installed meters. This industry unique calibration verification system keeps installed meters at work for flare gas management in production, refining, storage and distribution applications.

Many flare meter installations, either per plant edict or for compliance with environmental regulations, require regular validation of calibration. Traditionally, this has required a tedious and costly project to remove the meter from service and return it to a lab, which is particularly frustrating if the meter is found to still be within calibrated specifications.

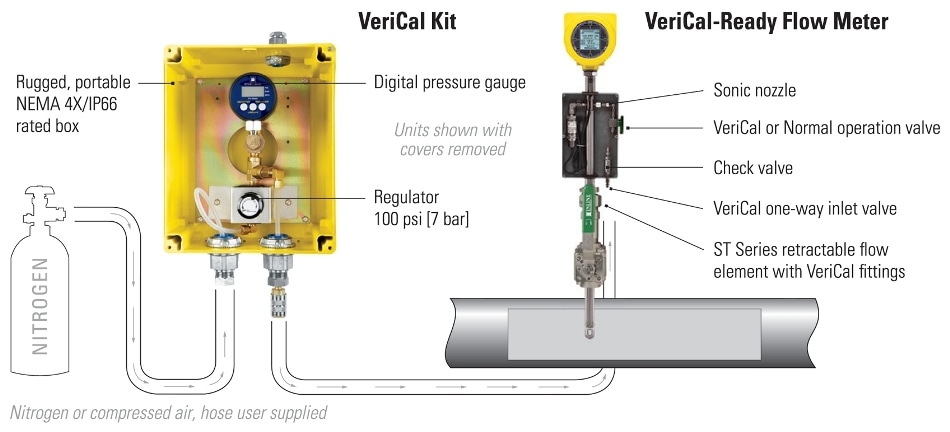

FCI’s exclusive VeriCal option eliminates the need for unnecessary de-installation. The VeriCal system provides a simple-to-use tool to verify the FCI flow meter is still within calibration without extracting the meter from pipe. The VeriCal system consists of a special VeriCal ready flow sensor, a portable VeriCal Kit (which can be used with any number of VeriCal-ready ST100 flow meters) and an additional benchmark calibration document to which field verification samples are compared

Setting a new industry benchmark in process and plant air/gas flow measurement, the ST100 Flow Meter offers the most feature-rich and function-rich electronics available. The ST100 Flow Meter’s performance delivers unsurpassed adaptability and value to meet plant gas flow measurement applications for today and tomorrow.

With a unique graphical, multivariable, backlit LCD display/readout, the ST100 Meter brings new meaning to the term “process information.” It provides the industry’s most comprehensive information with continuous display of all process measurements and alarm status, and the ability to interrogate for service diagnostics.

In-Situ VeriCal System for ST100 Flow Meter

The easy-to-use ST100 Meter stores up to five unique calibration groups to accommodate broad flow ranges, differing mixtures of the same gas and multiple gases, and obtains up to 1000:1 turndown. Also standard is an on-board data logger with an easily accessible, removable micro-SD memory card capable of storing 40 million readings.

With two multi-variable core model families, oil/gas engineers can choose from the ST and STP families. ST meters measure both mass flow and temperature, and the exclusive STP family adds a third parameter, pressure, making the ST100 the world’s first triple-variable thermal flow meter. Both families include single-point and dual-element models as configurations.

The ST100 Meter can be calibrated to measure virtually any process gas, including wet gas, mixed gases and dirty gases. The basic insertion style air/gas meter features a thermal flow sensing element that measures flow from 0.25 to 1000 SFPS (0.07 NMPS to 305 NMPS) with accuracy of ±0.75 percent of reading, ±0.5 percent of full scale.

Designed for rugged industrial processes and plants, ST100 Meter include service up to 850 ºF (454 ºC) and are available with both integral and remote (up to 1000 feet [300 meters]) electronics versions. The ST100 Meter is agency approved for hazardous environments, including the entire instrument, the transmitter and the rugged, NEMA 4X/IP67 rated enclosure. Global approvals in addition to a SIL 1 rating include ATEX, CPA, CRN, EAC/TRU CU, FM, FMc, FDT, GOST, IECEx, Inmetro and NEPSI.

The ST100 Flow Meter offers an extensive range of communications. No matter if the need is for 4-20 mA analog, frequency/pulse, alarm relays or digital bus communications such as HART, Fieldbus, Profibus or Modbus, the ST100 Meter is the solution.

Fluid Components International is a global company committed to meeting the needs of its customers through innovative solutions for the most challenging requirements for sensing, and measuring flow, pressure and temperature of gases.