Jan 6 2020

Self-mending, stretchy materials have the ability to use body heat to produce electricity, which in turn can be used to perpetually power wearable electronics.

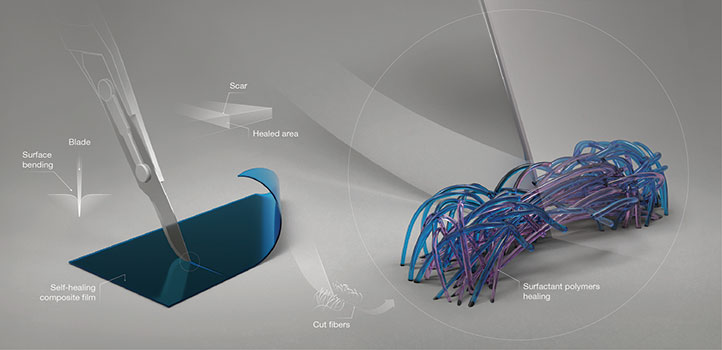

The mechanical and thermoelectrical self-healing process of the composite film. Image Credit: 2019 WILEY-VCH Verlag GmbH & Co.; Ivan Gromicho.

The mechanical and thermoelectrical self-healing process of the composite film. Image Credit: 2019 WILEY-VCH Verlag GmbH & Co.; Ivan Gromicho.

Researchers have carefully blended three curated organic compounds to create a prototype thermoelectric material that is not just self-healing and stretchy but produces its own electricity. The material is also sufficiently robust, enduring the stresses and strains of day-to-day use.

Sensors attached to the skin or used as implants are a more common means to collect biological data for medical and personal purposes. They have the ability to monitor crucial markers of human health including; blood pressure, heart rate, muscle motion, brain activity, the release of specific chemicals, and calories burned.

The aim of the research is to develop self-powered wearable technologies; however, these will necessitate a durable and reliable electricity source.

Thermoelectric materials make use of temperature gradients to produce electricity. They can power wearable technologies by utilizing body heat, thus avoiding the need for batteries. However, existing materials lack the strength, resilience, and flexibility to prevent permanent damage.

A research group from KAUST under the guidance of Derya Baran and Seyoung Kee has now combined PETOT:PSS (poly(3,4-ethylenedioxythiophene) doped with polystyrene sulfonate), an extremely conductive thermoelectric polymer with dimethyl sulfoxide, an organic compound that increases the performance of PETOT:PSS, and Triton X-100, a sticky, gel-like agent that boosts bonding of hydrogen with PETOT:PSS.

This final ingredient was essential for providing the stretchy and self-healing properties we needed.

Seyoung Kee, Researcher, King Abdullah University of Science and Technology

A 3D printer was used by the team to deposit the mixture into thick layers. The thermoelectric performance of these films was then tested under duress. Firstly, it was found that a temperature difference of 32 °C between both sides of the film produced the highest power output of 12.2 nW.

The self-healing behavior of the films was then tested by cutting them in half using a razor blade while an LED light was powered by the films.

Amazingly, the light did not go out during or after cutting. I repeated the cut ten times, but it continued to self-heal in less than one second and retained 85 percent of its power output.

Seyoung Kee, Researcher, King Abdullah University of Science and Technology

Moreover, when the film was stretched to about one-third longer compared to its original size, it still offered a stable power supply.

“Wearable electronics are under continuous strain, and their power supply is prone to breaking,” added Kee. “Our material can provide constant and reliable power because it can deform, stretch, and most importantly, heal itself.”

Although a power of 12 nW is not adequate to power various devices, other than maybe highly efficient transmitters and biosensors, the study demonstrates a promising start.

We have shown that such materials can be made easily using 3D printing, which is a very popular and practical technology. Next, we must find materials with even better thermoelectric properties so that we can generate greater power in the near future.

Seyoung Kee, Researcher, King Abdullah University of Science and Technology