Kistler, a major supplier of high precision, piezoelectric sensors to the automotive sector, is launching KiNOVA, a noise, vibration and harshness (NVH) data acquisition and analysis system.

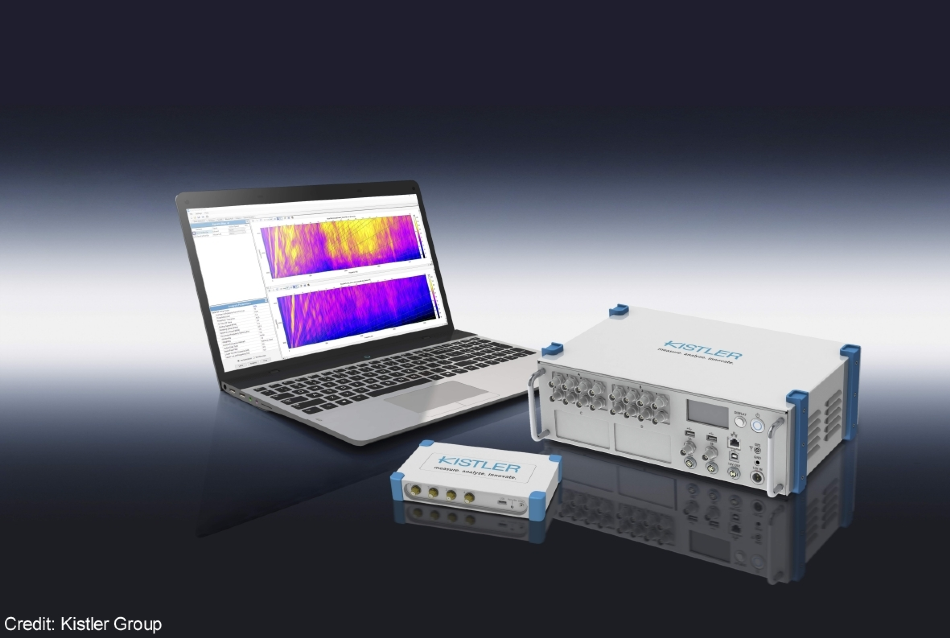

Kistler KiNOVA SYSTEM

Kistler KiNOVA SYSTEM

The new system provides a consistent level of precision throughout the measuring chain from sensor to analysis; a fully integrated and supported capability which extends from a wide range of sensors and powerful data acquisition hardware and sophisticated analysis software to on-site engineering support.

As legislation pushes for more efficient and environment friendly transportation and customer expectations regarding comfort increase, recent automotive developments has focused strongly on new and more efficient propulsion systems; hybrid and electric motors. The challenge for vehicle and powertrain manufacturers is not only to measure NVH with high accuracy, but also to analyse and interpret data in the most efficient way. To support this approach, the Kistler KiNOVA has been designed specifically to assist NVH engineers in the key phases of powertrain development and refinement no matter if it is a conventional, hybrid or electrical propulsion system.

Starting from the sensor, KiNOVA covers the complete workflow seamlessly - through measuring and analysing by means of the advanced application specific software: Using powerful and convenient application modules, the user can perform specific NVH testing on the powertrain. KiNOVA is compatible with a wide range of Kistler sensors and accelerometers and other third party sensors with IEPE / Voltage signals.

KiNOVA comes in two formats:

KiNOVA Lite: Ultra-portable, pocket-size and light-weight with 4 channels of voltage or IEPE inputs and analog inputs configurable for dynamic analysis or tachometer. Remarkable precision and signal conditioning with 24-bit resolution and 100 kHz sampling frequency combined with USB control and power. KiNOVA Capture software package provides data acquisition and signal processing tools comes as standard. The light-weight and USB-powered format makes KiNOVA Lite an ultra-portable device that does not compromise on accurate signal acquisition and processing and

KiNOVA Pro: A rugged and solid stackable unit with16 channels of Voltage or IEPE inputs that can be expanded to 32 channels per unit with 24-bit resolution, 100 kHz sampling frequency plus 2 dedicated tachometer channels. USB and Ethernet communications, a programmable standalone function, built-in solid state storage and internal battery deliver a flexible and powerful capability. The standard KiNOVA Acquisition software package provides comprehensive data acquisition and signal processing tools.

Both formats may be augmented with a range of specific solutions including;

KiSUITE HITS: Software for hammer impact testing for the KiNOVA Lite guides the user through all necessary steps to perform hammer impact tests.

KiSUITE NVH: The answer for all key needs of powertrain NVH engineering performing a broad range of functions to measure, analyse and process NVH for better and more efficient decision making.

KiSUITE SCA: Source Contribution Analysis allows identification and isolation of sources which contribute most to the response without the need for multiple intermediate FRF measurement.

Whether it’s conventional, hybrid or pure electric propulsion systems, KiNOVA can make a major contribution in the NVH area by supporting the development of advanced propulsion systems that not only meet legislative regulations but also provide the right sound and comfort experience.

The combination of the new KiNOVA data acquisition and analysis system and Kistler sensors delivers a powerful, new tool for engineers tasked with minimising unexpected noise and vibration under real world driving conditions.