Jun 5 2020

Physicists have developed the most sensitive strain sensor to date, with the ability to detect even a touch of a feather.

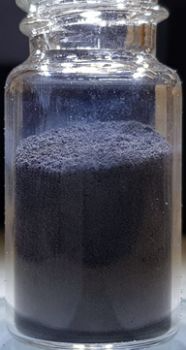

Photograph of G-balls resting in a glass vial. Each ball has a soft polydimethylsiloxane (PDMS) core and is coated with microscopic sheets of graphene. Image Credit: University of Sussex.

Photograph of G-balls resting in a glass vial. Each ball has a soft polydimethylsiloxane (PDMS) core and is coated with microscopic sheets of graphene. Image Credit: University of Sussex.

The Materials Physics Group at the University of Sussex designed the sensor that can extend to a higher strain of up to 80 times compared to existing, commercially available strain gauges. Further, the sensor can exhibit resistance changes 100 times higher compared to the most sensitive materials in research development.

The team is hopeful that the sensors could offer higher levels of sensitivity to wearable tech used to measure patients’ vital signs and to systems used for tracking the structural integrity of bridges and buildings.

The next wave of strain sensing technology uses elastic materials like rubber imbued with conductive materials such as graphene or silver nanoparticles, and has been in development for over a decade now. We believe these sensors are a big step forward. When compared to both linear and non-linear strain sensors referenced in the scientific literature, our sensors exhibit the largest absolute change in resistance ever reported.

Marcus O’Mara, School of Mathematical and Physical Sciences, University of Sussex

According to Alan Dalton, Professor of Experimental Physics at the University of Sussex, “This promising technology may prove especially useful in established fields such as healthcare, sports performance monitoring and rapidly growing fields such as soft robotics.”

Our research has developed cheap, scalable health monitoring devices that can be calibrated to measure everything from human joint motion to vitals monitoring. Multiple devices could be used across the body of a patient, connected wirelessly and communicating together to provide a live, mobile health diagnostics at a fraction of the current cost.

Alan Dalton, Professor of Experimental Physics, University of Sussex

The study was published in the Advanced Functional Materials journal and describes the method to integrate huge quantities of graphene nanosheets into a PDMS matrix in a structured, manageable fashion that leads to outstanding electromechanical properties.

According to the researchers, it is feasible to extend the technique to an extensive range of two-dimensional layered materials and polymer matrices. The sensors provide highly improved conductivity at all quantified loading levels with no evident percolation threshold.

Commercial gauge devices are hampered by comparatively low sensitivity and strain range, where gauge factors vary from 2 to 5 and highest strains of 5% or less, which leads to the increase in resistance by <25% and inhibiting high-strain sensing that is needed for bodily motion tracking.

The new sensor has the ability to detect strains below 0.1%, which is because of their higher gauge factor of approximately 20, and a strain of up to 80%, where the exponential response causes a change in resistance by a factor of over one million.

This enables both high-sensitivity low-strain sensing for high-strain measurement and pulse monitoring of chest motion and joint bending due to the record resistance change.

Commercial strain sensors, typically based on metal foil gauges, favor accuracy and reliability over sensitivity and strain range. Nanocomposites are attractive candidates for next generation strain sensors due to their elasticity, but widespread adoption by industry has been hampered by non-linear effects such as hysteresis and creep due to the liquid like nature of polymers at the nanoscale which makes accurate, repeatable strain readouts an ongoing challenge.

Dr Sean Ogilvie, Research Fellow in Materials Physics, University of Sussex

Ogilvie added, “Our sensors settle into a repeated, predictable pattern which means that we can still extract an accurate read-out of strain despite these effects.”

This study was supported by Alliance, a US-based rubber company.

“Alliance has a long history of innovation and it is vital for us to play an active role in leading edge rubber technology that uses a disruptive nanomaterial like graphene. It is critical that we partner with scientific leaders like Professor Alan Dalton at the University of Sussex,” stated Jason Risner, VP of Sales & Marketing, Alliance.

Risner added, “We are thrilled to see the products that could potentially come out of our partnership. Graphene is an astonishing material that can revolutionize our lives. Our company is proud to be on the cutting edge of something so new.”