Jun 8 2020

A team of researchers from the School of Engineering at Tufts University has created novel biomaterial-based inks that change color upon reacting to and measuring the chemicals discharged by the body (for example, in sweat and other possible bio-fluids) or in the surrounding setting.

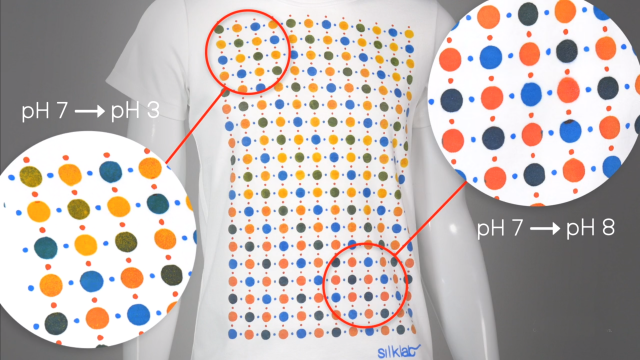

A T-shirt screen printed with pH-sensitive bio-active inks can provide a map of pH response on the wearer. Variations of bio-active inks can detect other molecules released by the body, or in the surrounding environment. Image Credit: Tufts University.

A T-shirt screen printed with pH-sensitive bio-active inks can provide a map of pH response on the wearer. Variations of bio-active inks can detect other molecules released by the body, or in the surrounding environment. Image Credit: Tufts University.

The biomaterial-based inks can be screen printed onto textiles such as shoes, clothes, or even face masks at high resolution and in intricate patterns, offering a comprehensive map of human exposure or response.

Reported in the Advanced Materials journal, the advancement in wearable sensing may concurrently detect and measure an array of molecules, biological conditions, and, potentially, microbes across the body’s surface using traditional uniforms and garments.

The use of novel bioactive inks with the very common method of screen printing opens up promising opportunities for the mass-production of soft, wearable fabrics with large numbers of sensors that could be applied to detect a range of conditions. The fabrics can end up in uniforms for the workplace, sports clothing, or even on furniture and architectural structures.

Fiorenzo Omenetto, Study Corresponding Author and Frank C. Doble Professor of Engineering, School of Engineering, Tufts University

When it comes to monitoring the health and performance of humans, wearable sensing devices have garnered a great deal of interest. A majority of wearable sensing devices have been developed by integrating electronics in wristbands, wearable patches, and other configurations that track either overall or localized physiological data, like blood glucose or heart rate.

Presented by Tufts University researchers, the study adopts a different, complementary method—that is, colorimetric, non-electronic detection of a conceptually very large number of analytes through sensing garments. These garments can be distributed to conceal extremely vast regions—right from a mere patch to the whole body, and beyond.

Biologically activated silk-based inks are the components that possibly constitute the sensing garments. Within these ink formulations, the soluble silk substrate can be altered by integrating numerous “reporter” molecules such as pH-sensitive indicators, or enzymes such as lactate oxidase to denote the lactate levels present in sweat.

While the former could indicate the health or dehydration conditions of the skin, the latter could denote the wearer’s levels of fatigue. Because of the versatility of the silk fibroin protein, several other derivatives of the inks can be produced by altering this protein with active molecules, like antibodies, enzymes, chemically sensitive dyes, etc.

The reporter molecules may not be stable on their own, but they can turn out to be shelf-stable when integrated into the silk fibroin in the ink formulation.

For screen printing applications, the inks are prepared by mixing them with a plasticizer (glycerol) or a thickener (sodium alginate). The bio-inks are screen printable and can be employed just like any ink created for screen printing applications; hence, it can be applied to clothing and also to numerous surfaces, like paper, plastics, and wood to create patterns that range between hundreds of microns and tens of meters.

Although the color changes indicated by the inks can offer a visual cue with regard to the absence or presence of an analyte, the use of camera imaging analysis scanning various other materials, including the garments, can collect more accurate data on quantity as well as high-resolution, sub-millimeter mapping.

The new technology is based on previous studies performed by the same group of scientists who produced bioactive silk inks developed for inkjet-printing applications to produce laboratory gloves, paper sensors, and petri dishes that can point to bacterial contamination by altering colors.

The screen printing approach provides the equivalent of having a large, multiplexed arrangement of sensors covering extensive areas of the body, if worn as a garment, or even on large surfaces such as room interiors.

Giusy Matzeu, Study First Author and Research Assistant Professor of Biomedical Engineering, School of Engineering, Tufts University

Matzeu continued, “Coupled with image analysis, we can obtain a high resolution map of color reactions over a large area and gain more insight on overall physiological or environmental state. In theory, we could extend this method to track air quality, or support environmental monitoring for epidemiology.”

The fact that the technique employs standard printing methods also paves the way to creative applications—something that was investigated by Laia Mogas-Soldevila, an architect and fresh PhD graduate at Tufts University in Omenetto’s SilkLab.

Mogas-Soldevila has also contributed to produce attractive tapestries, showing them in museums throughout Europe and the United States. The interactive displays enable visitors to spray different types of harmless chemicals onto the fabric and observe the changes occurring in the patterns.

This is really a great example of how art and engineering can gain from and inspire each other. The engineered inks open up a new dimension in responsive, interactive tapestries and surfaces, while the 1,000-year old art of screen printing has provided a foundation well suited to the need for a modern high resolution, wearable sensing surface.

Laia Mogas-Soldevila, Architect, Tufts University

The study was funded by grants from the U.S. Army Natick Soldier Research, Development and Engineering Center (W911QY-15-2-0001), the Office of Naval Research (N00014-19-1-2399), and a gift from the Stavros Niarchos Foundation.

Journal Reference:

Matzeu, G., et al. (2020) Large-scale patterning of reactive surfaces for wearable and environmentally deployable sensors. Advanced Materials. doi.org/10.1002/adma.202001258.