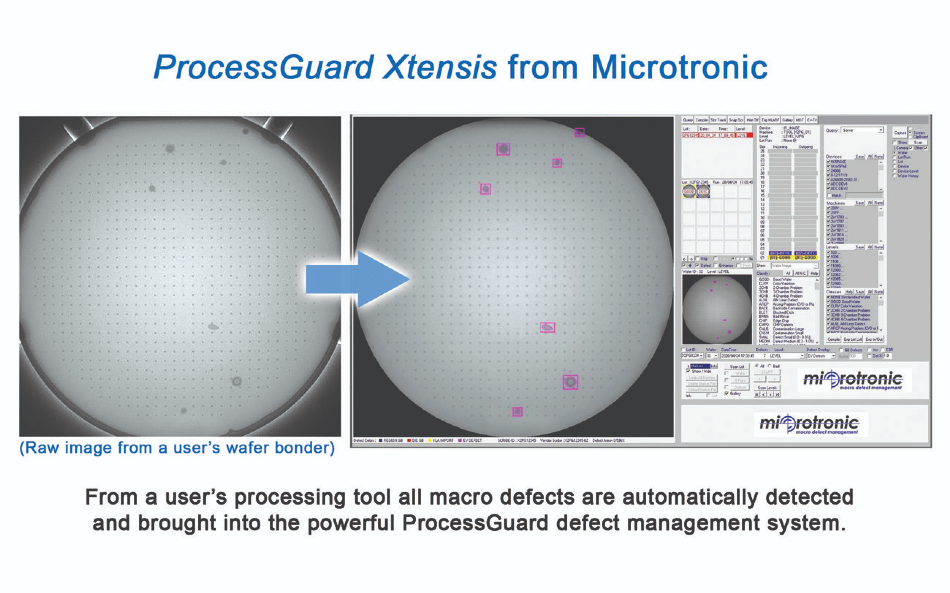

Microtronic, maker of high-speed full-wafer macro defect inspection systems and software, has just announced an innovative new way to automatically detect and manage wafer processing defects, beginning at the source – from inside specific types of processing tools. The new capability is called “ProcessGuard Xtensis” because it extends the power of “ProcessGuard” defect management to much more process equipment in the fab. Microtronic will be giving “live” demonstrations of the new system at the virtual SEMICON West 2020 exhibition.

“The key to ProcessGuard Xtensis – or PGX – is a very smart and fast new analytical software module we call the Trans-Imager,” said Microtronic CEO Reiner Fenske in making the announcement. “In real-time, Trans-Imager is able to extract and automatically analyze wafer images from within a processing tool – without the need for recipes. It detects macro defects, classifies wafers and transfers all the data into Microtronic's ProcessGuard software – which provides a rich array of additional defect management and analysis capabilities, both immediate and long-term. It extends ProcessGuard intelligence to many processes that previously had no way to detect defects.”

Fenske noted that the core of ProcessGuard Xtensis is the company’s well-known ProcessGuard software, which is in daily use worldwide and has already processed hundreds of millions of wafers. ProcessGuard compiles a comprehensive database of wafer defect information from the subject processing tool and allows users to analyze, organize, store and retrieve the details of every wafer run through the tool – by lot, date and time. The ProcessGuard database can also integrate notes and supplemental data from other defect inspections, microscopic analyses and more. All of this information can be quickly and easily accessed by everyone in the fab.

The company pointed out the importance of PGX speed and intelligence in spotting process excursions immediately – allowing corrective actions to be taken quickly, to reduce scrap and maximize yields. The software also provides important new reliability-enhancing controls. For example, the user can ink-out a "guard-band” safety zone around certain defects to ensure that potentially marginal die do not evade final test and reach the customer. Previously, ProcessGuard capabilities had only been available with EagleView™, Microtronic's popular macro defect inspection system. Now, with the development of the Trans-Imager, the power of ProcessGuard can be extended to individual processing tools directly.

Trans-Imager can be linked to a number of different types of processing equipment, such as bonders, etchers, metal deposition, CMP and more. Some of these tools may already have internal cameras that record the processing of each wafer; however, if a particular tool does not have a built-in camera, Microtronic can install one and link it to the Trans-Imager. In addition to wafer processing equipment, the Trans-Imager can also receive images from SEMs and optical microscopes, making it much easier to organize, file, store, and retrieve microscope images.

Microtronic has stated that it will be installing ProcessGuard Xtensis capabilities on tools currently residing within fabs, and it also will be working directly with equipment manufacturers who wish to offer PGX as an option on their new processing systems. For additional information, visit www.microtronic.com.