Small-cap, deep-tech company Archer Materials Limited has announced the building of a lab-on-a-chip device named A1 Biochip™.

Having recently hired lab-on-a-chop Biotechnologist Dr. Rebecca Soffe, the Archer team have made a step-change in advancing its graphene-based biosensor technology development to newly commence its lab-on-a-chip A1 Biochip™. Developing the biochip in-house should allow Archer to accelerate commercialisation of the biochip with a clear path to market.

A new commercial agreement now allows Archer to access the world-class semiconductor chip prototyping foundry for all its technology development, providing Archer with the opportunity to build its biochip in the same facility as its 12CQ quantum computing chip.

Commenting on the A1 Biochip™ development, Archer CEO Dr Mohammad Choucair said: “It is a global challenge to develop innovative biodevices that make the complex detection of disease safer and more reliable. Archer’s A1 Biochip™ technology aims to simplify disease detection at the point of care to potentially address an emerging multibillion-dollar industry.

“Archer’s biochip development involves miniaturising medical lab tests onto an integrated circuit, a single chip, that is only a few millimetres in size. This is incredibly difficult, and there are very few people the world that can do this type of work, however Dr Soffe has already made exciting advances on this front in only a few weeks since joining Archer”.

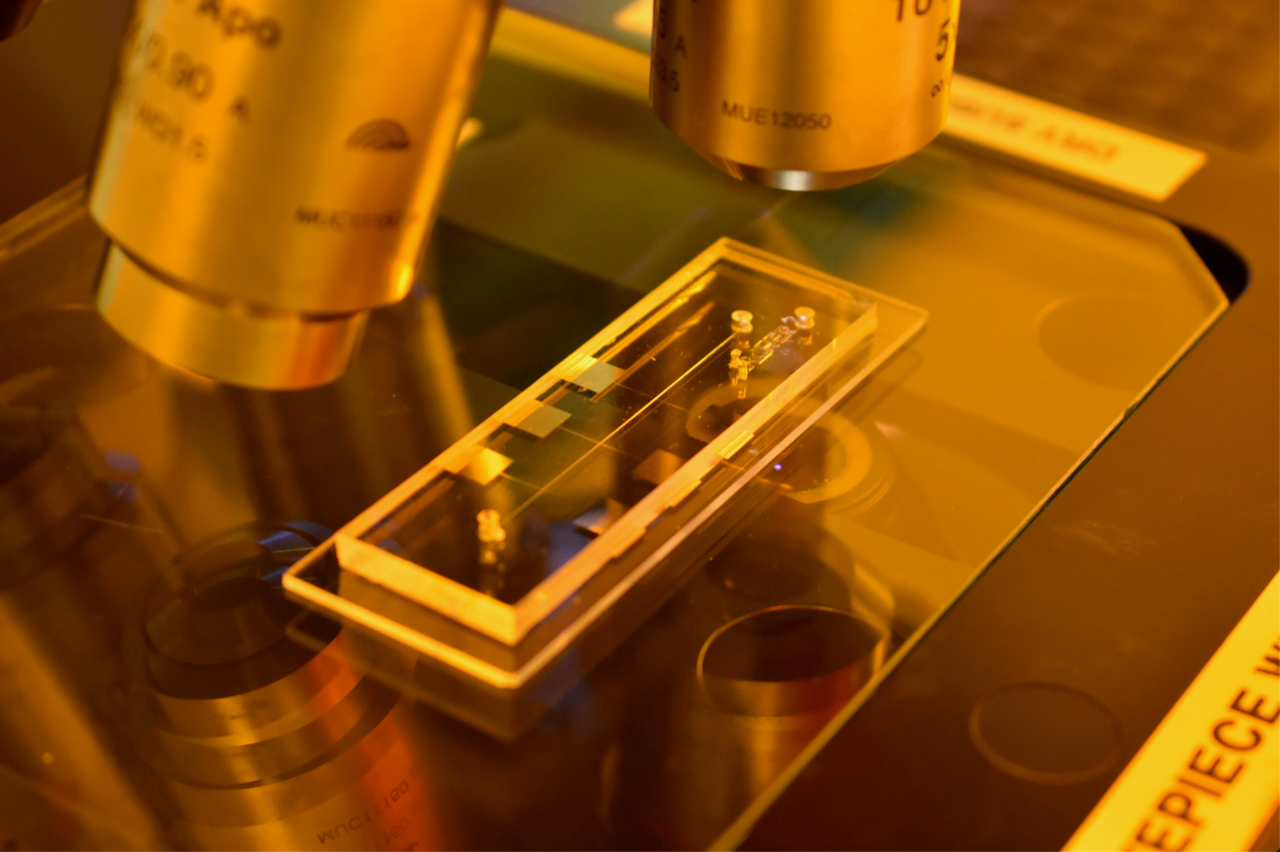

The first componentry of Archer’s A1 Biochip™ include on-chip microfluidic channels that allow for gas or liquid sampling (typical biological specimens) and miniaturised electrodes for the biosensing areas (microfabricated using gold and titanium). Further development will involve designing these components for further miniaturisation (micron to nanoscale), and are intended to incorporate graphene materials; both aspects which are required to validate commercial advantages of ultra-sensitivity and device integration.

The immediate next technology validation steps will be performed in the foundry and focus on translating the biochip components onto silicon wafers. This would enable the possibility of high-volume chip production and integration onboard electronic devices – both required for any future retail applications of the A1 Biochip™.