Nov 12 2020

Scientists from the Harvard John A. Paulson School of Engineering and Applied Sciences and the Wyss Institute for Biologically Inspired Engineering have now designed an ultra-sensitive, extremely durable strain sensor that can be integrated into textiles and soft robotic systems.

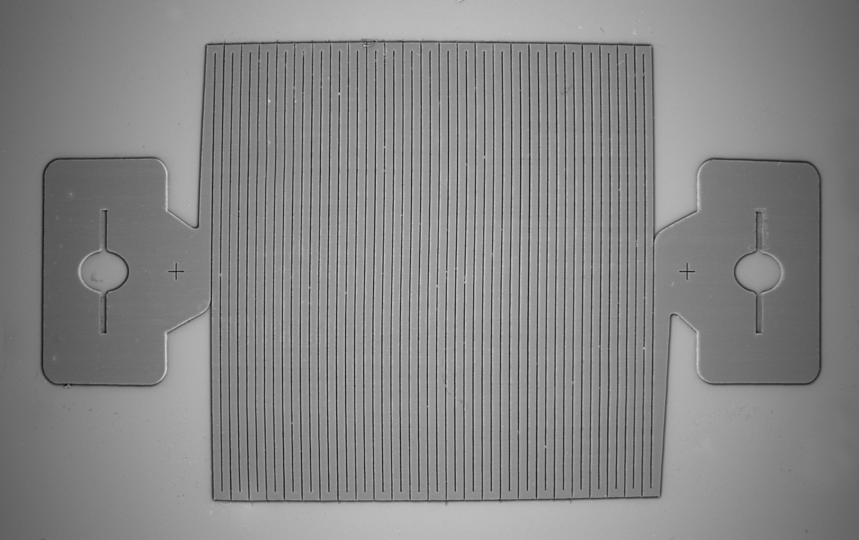

A close-up view of the sensor’s patterned conductive carbon fibers. The fibers are sandwiched between two prestrained elastic substrates. The overall electrical conductivity of the sensor changes as the edges of the patterned carbon fiber come out of contact with each other. Image Credit: James Weaver/Harvard SEAS.

A close-up view of the sensor’s patterned conductive carbon fibers. The fibers are sandwiched between two prestrained elastic substrates. The overall electrical conductivity of the sensor changes as the edges of the patterned carbon fiber come out of contact with each other. Image Credit: James Weaver/Harvard SEAS.

The study was recently published in the Nature journal.

Current soft strain gauges are really sensitive but also really fragile. The problem is that we’re working in an oxymoronic paradigm—highly sensitivity sensors are usually very fragile and very strong sensors aren’t usually very sensitive. So, we needed to find mechanisms that could give us enough of each property.

Oluwaseun Araromi, Research Associate, Materials Science and Mechanical Engineering, Harvard John A. Paulson School of Engineering and Applied Sciences

Araromi, the first author of the paper, is also a research associate at the Wyss Institute. Finally, the team developed a design that appears and acts quite similar to a Slinky.

A Slinky is a solid cylinder of rigid metal but if you pattern it into this spiral shape, it becomes stretchable. That is essentially what we did here. We started with a rigid bulk material, in this case carbon fiber, and patterned it in such a way that the material becomes stretchable.

Oluwaseun Araromi, Research Associate, Materials Science and Mechanical Engineering, Harvard John A. Paulson School of Engineering and Applied Sciences

The pattern is called a serpentine meander due to its sharp ups and downs that look like a snake’s slithering. The patterned conductive carbon fibers are then interspersed between two prestrained elastic substrates.

The sensor’s overall electrical conductivity gets altered as the patterned carbon fiber’s edges come out of contact with each other, just like the way the separate spirals of a slinky come out of contact with each other when both its ends are pulled. This process takes place even with very less strain, which is essential to the high sensitivity of the sensor.

In contrast to existing highly sensitive stretchable sensors, which are based on exotic materials like silicon or gold nanowires, this sensor does not need unique manufacturing methods or even a cleanroom. It can be created by using any conductive material.

The resiliency of the sensor was tested by the team by running it over with a car, hitting it with a hammer, stabbing it with a scalpel, and throwing it in a washing machine 10 times. The sensor remained unaffected after each test.

To show its sensitivity, the team integrated the sensor into a fabric arm sleeve and asked a volunteer to do various gestures with their hand, including an open palm, fist, and pinching motion.

The sensors detected even the small changes in the forearm muscle of the volunteer via the fabric, and a machine-learning algorithm was successful in classifying such gestures.

These features of resilience and the mechanical robustness put this sensor in a whole new camp.

Oluwaseun Araromi, Research Associate, Materials Science and Mechanical Engineering, Harvard John A. Paulson School of Engineering and Applied Sciences

This kind of sleeve could be utilized in applications ranging from virtual reality simulations and sportswear to clinical diagnostics for neurodegenerative diseases, such as Parkinson’s disease.

Harvard’s Office of Technology Development has filed to safeguard the intellectual property related to this project.

“The combination of high sensitivity and resilience are clear benefits of this type of sensor,” stated Robert Wood, the Charles River Professor of Engineering and Applied Sciences at SEAS and senior author of the study. “But another aspect that differentiates this technology is the low cost of the constituent materials and assembly methods. This will hopefully reduce the barriers to get this technology widespread in smart textiles and beyond.”

“We are currently exploring how this sensor can be integrated into apparel due to the intimate interface to the human body it provides,” noted Conor Walsh, the Paul A. Maeder Professor of Engineering and Applied Sciences at SEAS and co-author of the study. “This will enable exciting new applications by being able to make biomechanical and physiological measurements throughout a person’s day, not possible with current approaches.”

The study was co-authored by Moritz A. Graule, Kristen L. Dorsey, Sam Castellanos, Jonathan R. Foster, Wen-Hao Hsu, Arthur E. Passy, James C. Weaver, Senior Staff Scientist at SEAS, and Joost J. Vlassak, the Abbott and James Lawrence Professor of Materials Engineering at SEAS.

The study was financially supported through the university’s strategic research alliance with Tata. The 6-year, $8.4M alliance was established in 2016 to progress Harvard innovation in fields such as the internet of things (IoT), wearable technologies, and robotics.

Sensor for smart textiles survives washing machine, cars and hammers

Video Credit: Harvard John A. Paulson School of Engineering and Applied Sciences.

Journal Reference:

Araromi, O. A., et al. (2020) Ultra-sensitive and resilient compliant strain gauges for soft machines. Nature. doi.org/10.1038/s41586-020-2892-6.