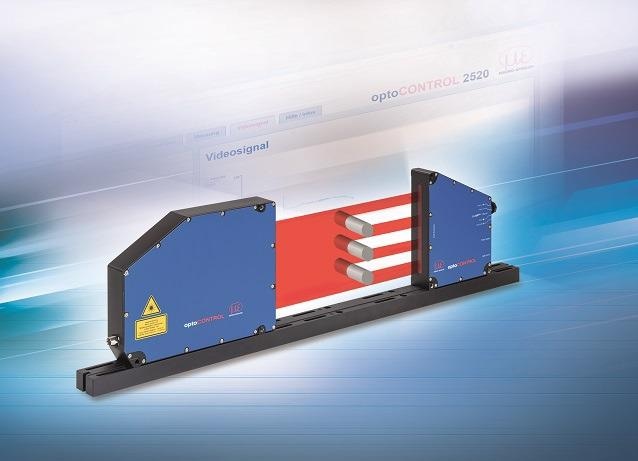

Precision sensor supplier Micro-Epsilon has extended its optoCONTROL 2520 series of optical laser micrometers with the optoCONTROL 2520-95, which provides double the measuring range (95 mm) of the existing optoCONTROL 2520-46. The increased range allows for measurements on larger diameter parts without the need to use or combine additional sensors.

The new optoCONTROL 2520-95 offers double the measuring range (95 mm) of the existing optoCONTROL 2520-46.

The new optoCONTROL 2520-95 offers double the measuring range (95 mm) of the existing optoCONTROL 2520-46.

The optoCONTROL 2520-95 is a compact laser micrometer characterised by its high accuracy, high repeatability and a large measuring range of 95 mm. The micrometer is flexible too; measurements can be taken at any position within the light curtain whilst preset optimum distances are selectable in the controller. Due to its high linearity (<± 15 µm), high repeatability (≤ 6 µm) and measuring speed (2.0 kHz), the sensor is suitable for all applications where large measuring ranges are required.

The optoCONTROL 2520 series outputs up to 2,500 measurements values per second depending on the measuring range. Measurement modes such as Edge Tracking, Diameter, Gap and Centre Axis can be selected, whilst the Segment mode allows multiple targets to be measured that are within the optical beam. An option with an angled (90-degree) flat receiver is also available on both ranges for measurements in confined spaces.

Configuration of the sensor is performed via the web interface, enabling parameters to be set up including video signal, filter and the various measuring modes. The optoCONTROL 2520 micrometers are equipped with an integral controller and are rated as laser class 1M. Analogue, RS422, Ethernet and EtherCAT outputs are provided to simplify integration of the sensor into the customer’s own production control environment. Profinet and Ethernet/IP can also be used via the IF2030 interface converters.

Glenn Wedgbrow, Business Development Manager at Micro-Epsilon comments: “The optoCONTROL 2520-95 is extremely versatile and so will find applications across many different industry sectors in the UK, from food and pharmaceuticals, to automotive and machine building. The micrometers can be set up in production lines to inspect continuous material or single parts. For example, in strip material processing applications and cutting machines, several strips can be measured simultaneously by using multi-segment measurement. In addition, the sensor is ideal for hose and extruder products, including bars and plastic pipes.”

Wear-free and a long service life

All optoCONTROL laser micrometers from Micro-Epsilon work without rotating mirrors and so are completely wear-free. The parallel light curtain is created by using special optics in the light source. High quality components in the receiving optics, including filters and lenses, enable the high accuracy of the micrometers.

The optoCONTROL 2520 series of laser micrometers from Micro-Epsilon offer high accuracy and measuring rates. The improved linearity, different measuring ranges and variable mounting distances between transmitter and receiver, allow for a wide range of dimensional measurement applications in production control, quality control and inline inspection.