Double sheet detection where consistent and reliable detection of one or more layers of materials such as; foil, paper, cardboard, labels, or even thin metal sheets can present complex challenges. If issues are not resolved they can lead to machine downtime, wasted materials, and in some cases, expensive repair costs. This can occur across a myriad of applications such as printing, packaging, automotive, and finishing industries.

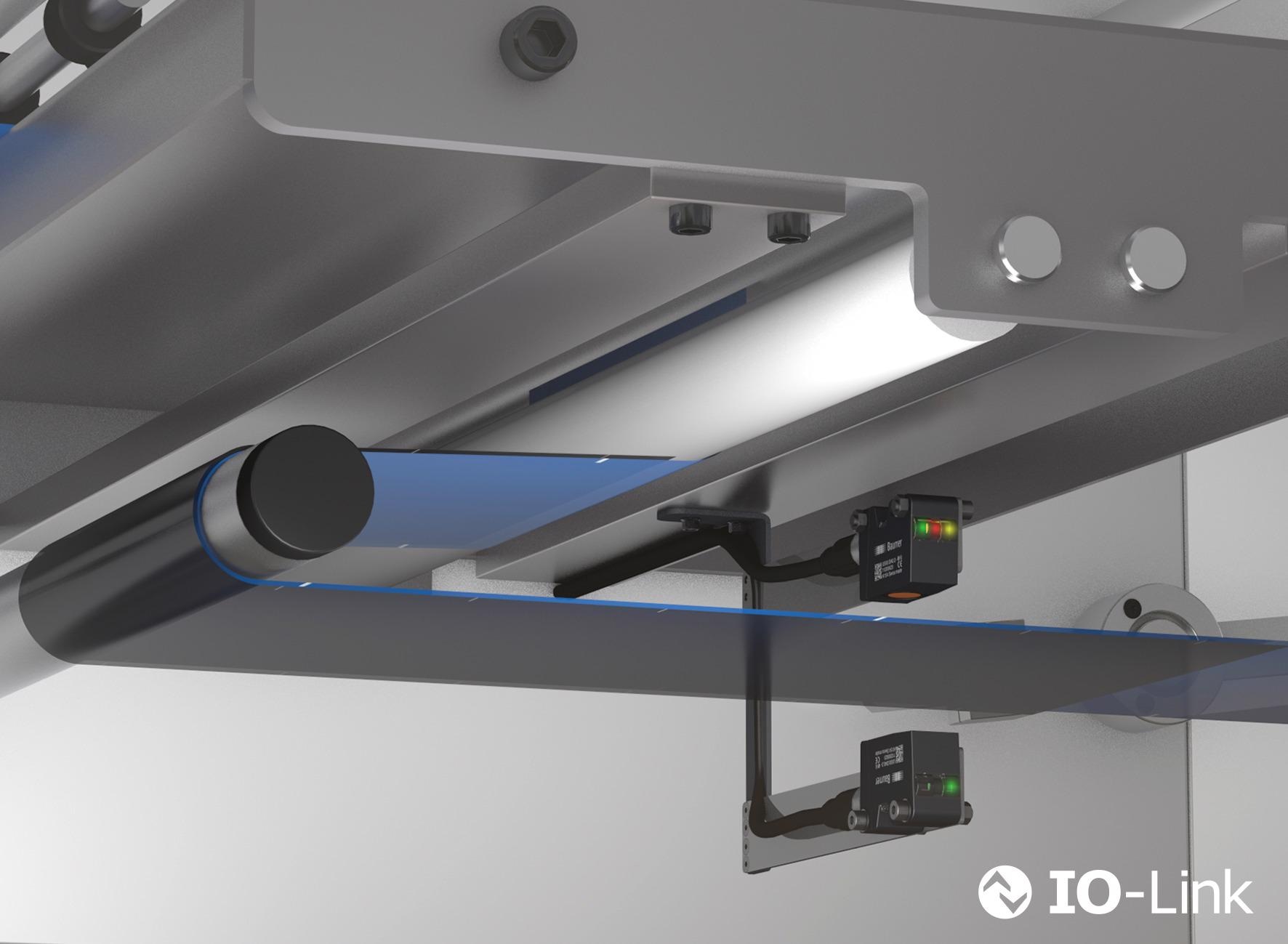

Image Credit: BAUMER

Ultrasonic sensors usually provide the best solution such as those available from sensing and instrumentation specialist BAUMER. The latest addition to their range of high-performance ultrasonic sensors the U300, U500, and UR18, represents two product families that offer effective and extremely flexible solutions for double sheet detection across a wide range of materials.

These new sensors offer important functions and adjustment options which means they can be adapted to suit many double sheet detection applications, the most important of which is a through-beam sensor. The receiver of the through-beam sensor is equipped with two binary switching outputs as well as an IO-Link interface and is designed to reliably detect the most common materials in the standard setting.

However, if critical material thicknesses occur the sensor can be adjusted for these more challenging demands through parameter configuration. In either IO-Link or switching mode, the sensor reliably detects one, two, or more layers of materials such as foil, paper, cardboard, labels, or thin metal sheets.

In addition to double sheet detection, the sensors can also be used for film tear detection, bonding surface detection, and also label detection which is where more diverse materials and varied thicknesses occur as well as more varied installation conditions.

These situations are no problem for Baumer ultrasonic sensors as the through-beam can be easily adjusted to suit the materials and other critical factors, such as distance.

Thanks to the IO-Link interface the application parameters can be quickly and easily adjusted to suit the sound-absorbing materials. This ensures reliable detection with the process values related to the material being displayed to enable the switching thresholds to be set accordingly.

To help with mounting the sensor, the transmitter housing and the corresponding receiver can also be selected depending on the installation site. Also, it’s possible to combine the cubic receiver (U500) with the cylindrical transmitter (UR18) which ensures optimum flexibility in the overall design of the detection system.

To emphasize the flexibility, ease-of-installation, and reliability of these sensors all the variants of the U300, U500, and UR18 available from Baumer mean that many other IO-Link parameters can be used by the through-beam sensor to suit the widest range of application requirements.