The perceived quality of smooth, defect-free surfaces is determined by the look and feel, colour and shape consistency of the surface. High quality finished surfaces are therefore a challenge for many industries, including automotive and aerospace components, domestic appliances, entertainment devices and consumer electronics.

Although inspectors are able to recognise a high proportion of surface defects reliably and quickly, visual evaluation is often subjective and depends heavily on several factors, including tiredness, lack of concentration and varying lighting conditions. The aim of surface inspection is to achieve an objective and reproducible evaluation of the surface deviations in order to quickly and reliably make decisions with respect to component tolerances.

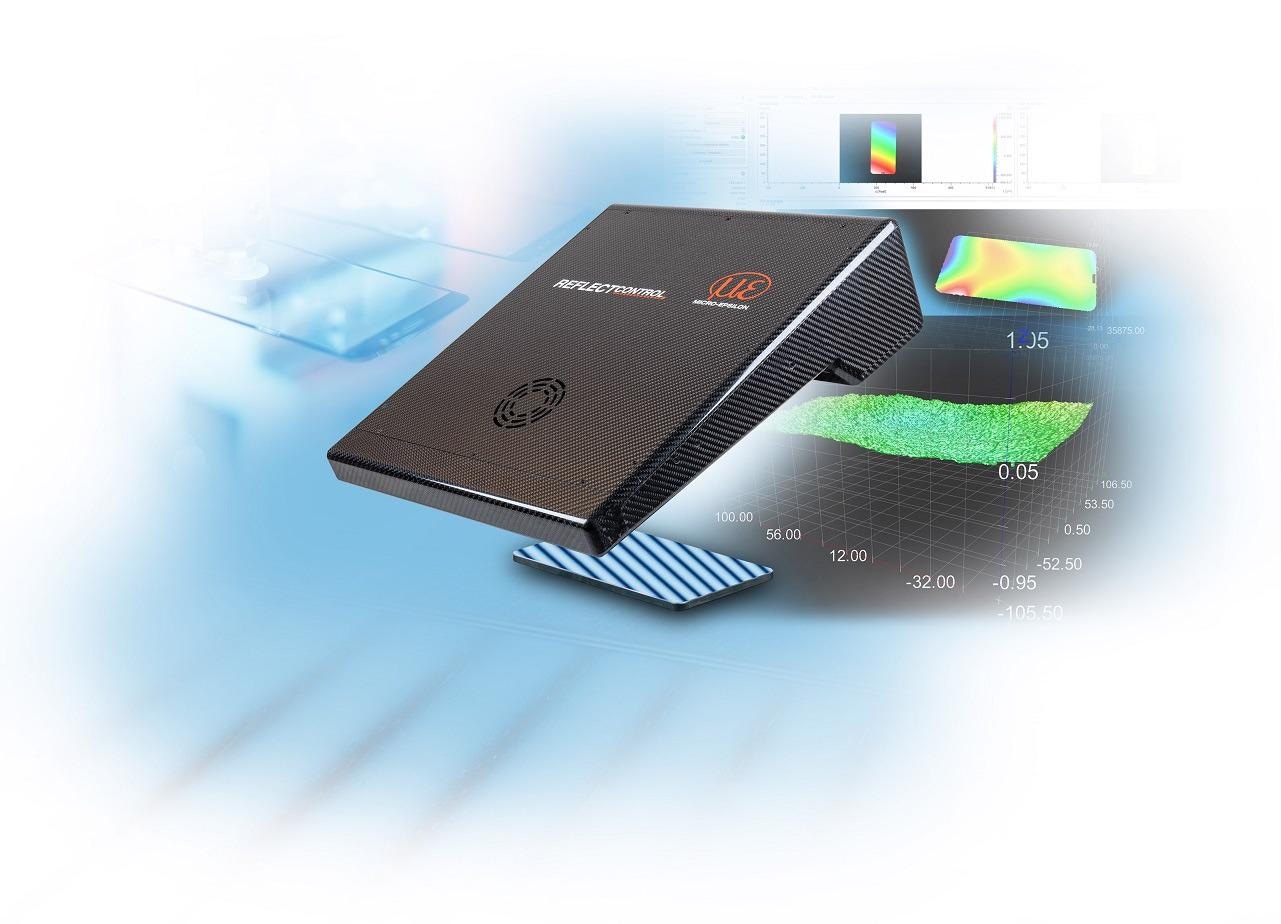

The new reflectCONTROL Sensor performs 3D surface inspections of glossy and shiny surfaces. Image Credit: Micro-Epsilon

The new reflectCONTROL Sensor performs 3D surface inspections of glossy and shiny surfaces. Image Credit: Micro-Epsilon

In order to help solve these challenges, Micro-Epsilon has introduced reflectCONTROL Sensor, a compact 3D non-contact surface inspection system for defect detection of reflecting surfaces such as polished or painted metals, glass, mirrors, painted plastics and galvanised surfaces.

Based on the deflectometry principle, reflectCONTROL Sensor projects a striped pattern onto the surface of the measurement object. Defects on the surface cause distortions of this striped pattern, which are then recorded by cameras and evaluated by software.

When inspecting flat surfaces, reflectCONTROL Sensor detects flatness deviations in the range of a few micrometers. Inspection cycles are less than two seconds per measuring position and the sensor provides a large measuring field. The sensor can be used in a stationary mode for monitoring processing/assembly lines or mounted on a robot to perform inline inspection. The sensor is therefore suitable for a variety of 100% inspection tasks including, for example, 3D shape inspection of wafers in semiconductor production, quality inspection of flat glass in smartphone production, and surface inspection of mirrors in automotive head-up displays.

reflectCONTROL options

The reflectCONTROL RC130 is intended for shape defect measurements of shiny objects. This sensor provides a 3D image of the surface which allows the topology of the components to be determined. The RCS130 model is specially optimised for measurement and inspection tasks in production and assembly lines. The sensor also has a GigE Vision interface that offers GenICam-compliant data.

The reflectCONTROL RCS110-245 with integrated controller is designed for stationary measurements or integration into machines. This compact sensor detects anomalies on shiny surfaces which are processed and displayed as reflectivity and curvature images by software. GigE Vision enables the transfer of surface images to a wide range of image processing software packages for further analyses.

Easy-to-integrate

The 3DInspect software offers a convenient user interface for reflectCONTROL sensors. This user-friendly software enables fast commissioning and evaluation of the sensor, set up and optimisation of parameters and ensures the correct positioning of the measuring object and sensor. The software can be used to create and manage parameter sets for different measuring tasks, as well as for starting data acquisition. The images obtained are visualised and can be saved for further processing. 3DInspect is particularly helpful for systems integrators, as it allows them to access all GenICam parameters, which simplifies the integration of the software.

reflectCONTROL is equipped with an easy-to-integrate Software Development Kit (SDK), which is based on the GigE Vision and GenICam industry standards including function blocks for network configuration and sensor connection; comprehensive sensor control; control of image transfer; management of user-defined parameter sets; and C++ example programs and documentation.