Boosting efficiency through digitalization - almost no branch of industry can evade it. Also operators of press shops are increasingly networking their production. But - regardless of whether it's a single press or press lines - it's not always necessary to replace the entire plant in order to stay up to date Retrofitting existing lines, true to the principle of "sensible evolution instead of cost-intensive revolution", is often the order of the day.

Digitization in the press shop. Image Credit: IDS Imaging Development Systems GmbH

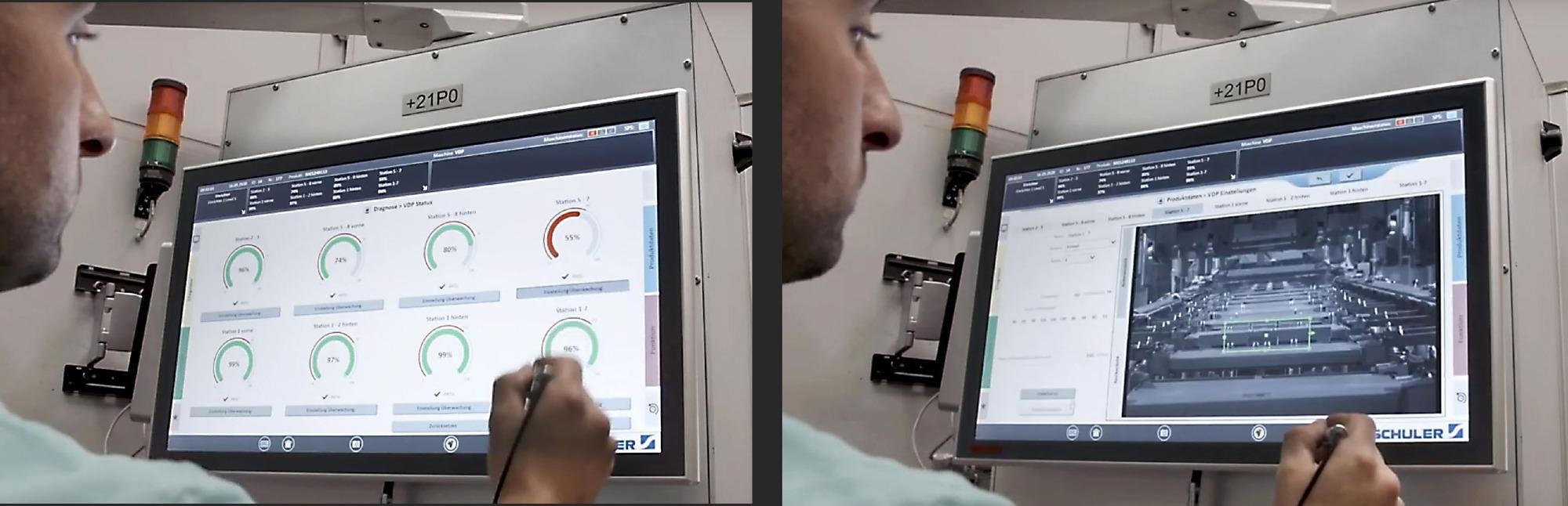

With Visual Die Protection, Schuler Pressen GmbH from Göppingen offers a solution for avoiding expensive die damage and its consequential costs in stamping and forming technology - retrofittable for existing lines. Equipped with industrial cameras from IDS Imaging Development Systems GmbH and intelligent software, the production process can be monitored as required.

Application

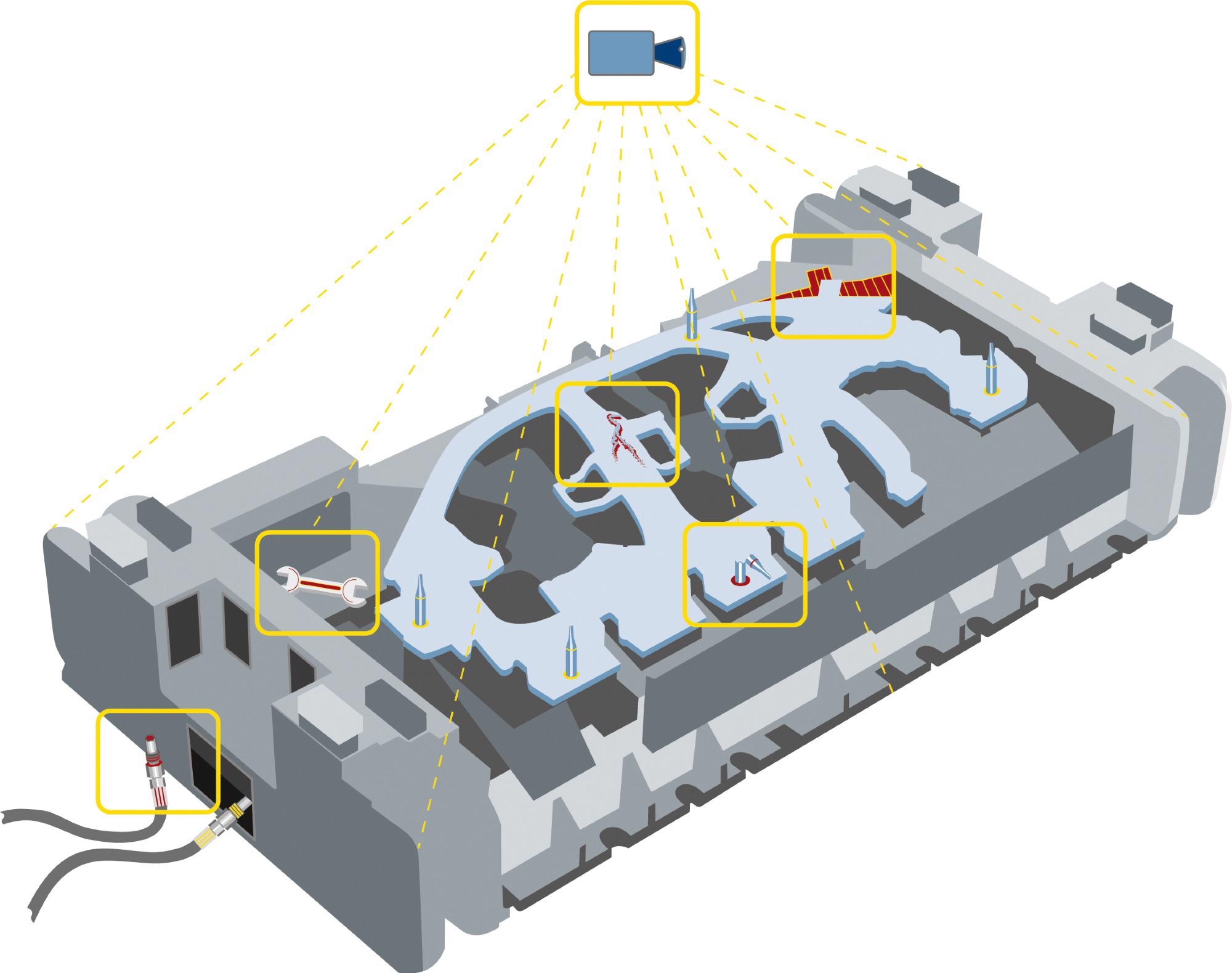

The principle of the system is simple: Visual Die Protection (VDP) detects possible causes of die damage in the press shop at an early stage and stops the line in fractions of a second before damage and downtime occur. Different monitoring functions can be set up for the various areas in the press installation space. This way, a wide range of error sources can be covered to prevent unforeseen incidents. The probability of failure is reduced and the safe operation of the systems is ensured.

The control functions range from checking the component position to foreign object detection and in-process inspections to the targeted monitoring of individual tool functions. For example, if a foreign object, such as a scrap of sheet metal from the previous press pass, is detected in the die, the press stops automatically so that the foreign object cannot push into the die surfaces or cause damage.

The system detects unexpected causes of faults and stops the press. Image Credit: IDS Imaging Development Systems GmbH

The system can be used for a wide range of monitoring tasks, even outside the actual pressing plant. Thanks to the easy retrofitting of existing systems and the wide range of applications, the monitoring functions can be set up in just a few minutes. Accordingly, customers benefit immediately from camerabased tool protection. That also applies to non-Schuler systems. With the help of product data handling, even monitoring of already set-up tools can be loaded and monitored from the first press stroke Camera

Camera

The image data on which the Schuler system is based is supplied by uEye CP industrial cameras from IDS. CP stands for "Compact Power" and symbolizes compact, visual power packs for industrial applications of all kinds. They offer maximum functionality with extensive pixel pre-processing and are perfect for multi-camera systems thanks to the internal 120 MB image memory for buffering image sequences.

The GigE cameras with a size of only 29 x 29 x 29 millimeters score particularly well in terms of light sensitivity, dynamic range and color reproduction. This makes them predestined for applications that need to deliver a perfect result even in low light conditions, such as in quality assurance or automation.

The quality of the image data convinced us. Even under rather unfavorable lighting conditions in press shops, the camera provides perfect source material for our inspection systems.

Christoph Pölzl , Project Manager in the Digital Solutions division, Schuler Pressen GmbH

For integration, the company used the IDS Camera Manager, a central and convenient tool for managing all uEye industrial cameras.

One or more IDS industrial cameras monitor the tool room. Image Credit: IDS Imaging Development Systems GmbH

Outlook

Visual Die Protection has been on the market since 2019 and has since established itself in stamping and forming technology as a reliable visual protective tool. With artificial intelligence and industrial cameras, it provides a clear view in the press shop.

For the future, we expect a continuously growing market.

Christoph Pölzl , Project Manager in the Digital Solutions division, Schuler Pressen GmbH.

In addition to process and tool monitoring, further applications in the area of in-process quality monitoring are added. The diagnostic tools for linking image and process data are also constantly being expanded. So the evolution continues and perhaps in the end it will lead to a small revolution?

About the camera family https://en.ids-imaging.com/ueye-industrial-cameras.html#ueye-cp