In minimally invasive surgeries, catheters play a major role and facilitate interventions like insertion of implants, blood clot removal, or targeted administration of drugs.

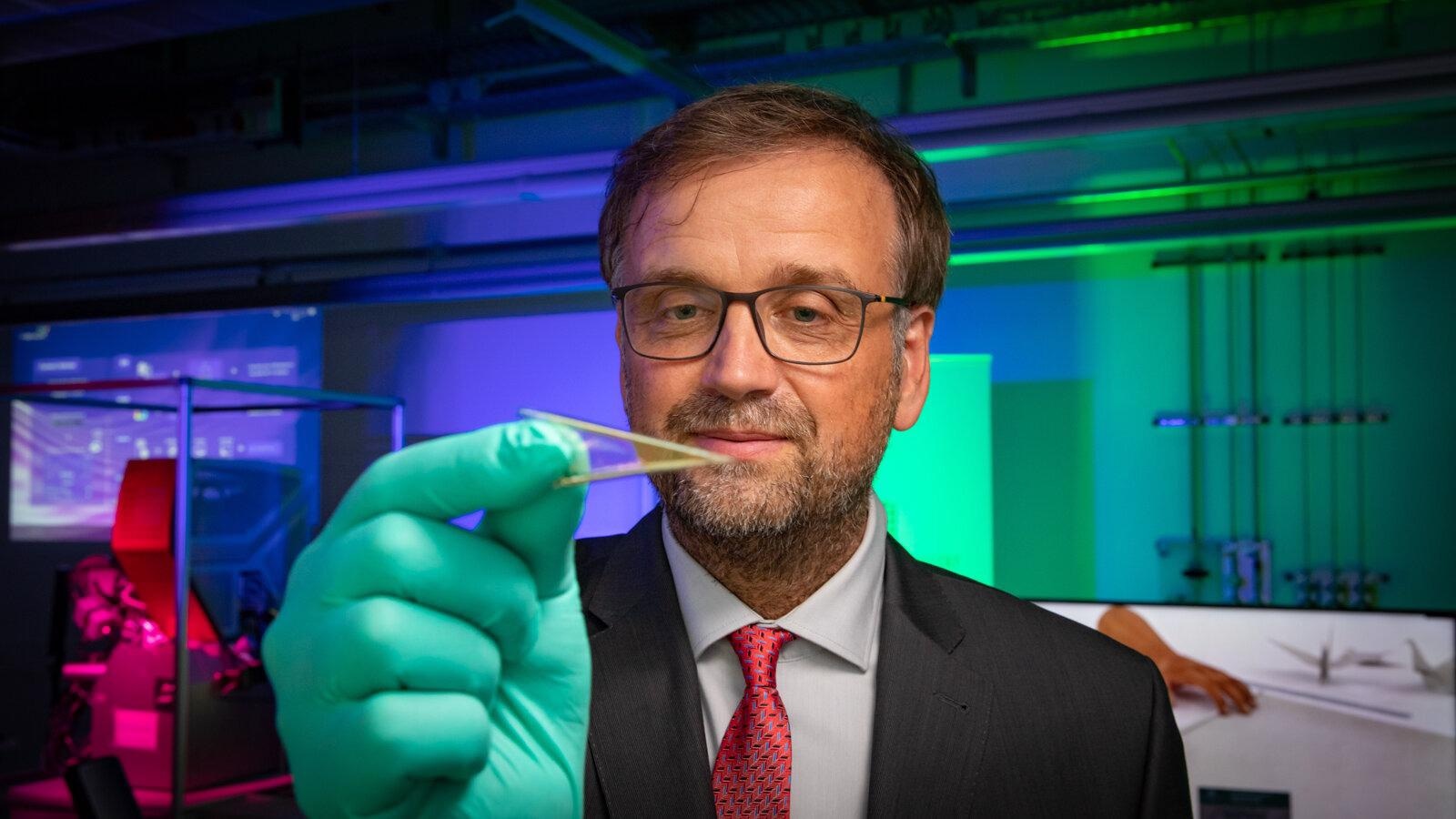

Prof. Dr Oliver G. Schmidt is a pioneer in the exploration and development of extremely small, shapeable, and flexible microrobotics. The photo shows him with an ultra-flexible microelectronic foil between his fingers. Image Credit: Jacob Müller.

Prof. Dr Oliver G. Schmidt is a pioneer in the exploration and development of extremely small, shapeable, and flexible microrobotics. The photo shows him with an ultra-flexible microelectronic foil between his fingers. Image Credit: Jacob Müller.

If the catheter procedure is less invasive, then the risk of medical complications is often lower and shorter recovery time. However, there are restrictions. For example, most sensors and actuators are still combined into electronic catheters manually.

Moreover, the placement and control of catheters in the body are restricted as the surgeon should externally maneuver the tiny instruments in a complex environment or manipulate through robotic assistance.

This has major drawbacks for miniaturization and using flexible structures that must adapt to the body for specifically gentle surgical use. Furthermore, combining additional functions and sensors into micro-catheters has been challenging, thus hampering their prospective applications.

Prof. Dr Oliver G. Schmidt, head of the Professorship for Material Systems for Nanoelectronics, designated Scientific Director of the Center for Materials, Architectures and Integration of Nanomembranes (MAIN) at Chemnitz University of Technology and former Director at the Leibniz Institute for Solid State and Materials Research (IFW Dresden), led researchers from IFW Dresden and the Max Planck Institute for Molecular Cell Biology and Genetics (CBG) to present the smallest ever flexible, microelectronic microcatheter.

Smart Functions—as Thin as a Hair: New Type of Biomedical Tool

The electronic components for sensors and actuators in this smart microelectronic tool, used for minimally invasive surgery, are already combined into the catheter wall from the outset.

Due to the special manufacturing method, the embedded electronic components have no effect on the size of our catheters, which can thus be as thin as a single hair.

Boris Rivkin, Study Lead Author, Chemnitz University of Technology

Rivkin is pursuing his doctoral graduation at Chemnitz and his dissertation at Leibniz IFW Dresden. The diameter of the instruments is only 0.1 mm and they are highly resilient, flexible, and biocompatible.

Using microchip technologies to manufacture the microcatheters allows us to generate completely new types of biomedical and multifunctional tools.

Dr Oliver G. Schmidt, Professor and Head of the Professorship for Material Systems for Nanoelectronics, Scientific Director of the Center for Materials, Architectures and Integration of Nanomembranes (MAIN), Chemnitz University of Technology

Smart tools such as these could find applications in, for instance, minimally invasive treatments of pancreatic surgery, aneurysms, or vascular malformations.

Flexible and Equipped for Diverse Applications: New Applications for Minimally Invasive Surgery

Prof. Schmidt and his colleagues combined magnetic sensors for navigation and positioning into the micro-catheter. Similar to a compass, the tracking depends on weak magnetic fields rather than contrast agents or harmful radiation. Thus, it can be used in deep tissue and under dense materials like skull bones.

The microelectronic microcatheter also combines a channel for fluids that can be used to deliver liquid embolic agents or microfluidic system drugs directly to the point of use. The catheter tip is provided with a minuscule gripping instrument that enables the catheter to clutch and move microscopic objects.

Potential applications of this tool are the removal of blood clots or minute tissue samples. Such a highly versatile use of embedded microelectronics is rendered viable by integrated electronic components that work based on the Swiss-Roll Origami Technology.

Using this technology, the researchers can develop very complex microelectronic sensors and actuator circuits on a chip, which can then be activated to roll up into a Swiss-Roll microtube structure. The several windings of the Swiss-Roll architecture considerably increase the usable surface area and monolithically combine microelectronics, sensors, and actuators into the small-sized wall of the tubular microcatheter.

Prof. Schmidt and his colleagues have pioneered this technology for some time. Very thin, shapeable polymer films have been useful for developing a microtube architecture that can geometrically adjust to various other objects, such as cuff implants as bioneural interfaces. This technology targets another application scenario—catalytic micromotors and platforms used in electronic components to develop microelectronic swimming robots.

The microelectronic microcatheter closes the gap between electronically improved instruments and the size demands of vascular interventions in submillimeter anatomies. More sensor functions can be added to widen the range of prospective applications in the future.

For instance, sensors used for biomolecule detection, analysis of blood gas, and identifying physiological parameters like temperature, blood pressure, and pH are viable. Thanks to this technology, completely new and versatile applications for minimally invasive surgery are now within reach.

Journal Reference:

Rivkin, B., et al. (2021) Electronically integrated microcatheters based on self-assembling polymer films. Science Advances. Available at: https://www.science.org/doi/10.1126/sciadv.abl5408.